About Shuliy-Recycling Machinery Manufacturer

We are a professional manufacturer of environmental protection and recycling equipment, committed to delivering efficient and reliable solutions to customers worldwide. With over 10 years of experience, we provide a full range of services—from equipment design to after-sales support—to help clients build stable and efficient recycling systems.

Our main products include plastic recycling machines, tire recycling machine, paper recycling machines (egg tray machines), metal recycling equipment, and fiber recycling systems, turning various waste materials into reusable resources.

Waste Recycling Plants-Complete Recycling Solutions

We provide customized recycling solutions for our customers, not only offering individual machines but also focusing on complete line planning and system integration. Whether it’s a small recycling facility or a large-scale industrial project, Shuliy can deliver efficient and reliable recycling systems covering a wide range of fields, including plastic recycling (film, rigid plastics, PET bottles), paper recycling (egg tray production line), metal recycling (waste metal compression and processing), and fiber recycling (used clothes, cotton waste). We help our clients achieve environmentally friendly and efficient resource reuse.

Plastic Film Recycling Machine | Plastic Film Recycling Granulation Line

- Applicable Raw Materials: cement bag, waste agricultural film and greenhouse film, packaging films, woven bags, shrink wrap, stretch film, rubbish bag, jumbo bags, in-house (post-industrial) film waste, etc.

- Plastic Material: PP, LDPE, HDPE, LLDPE, PVC

- Final Product: Recycled plastic granules (suitable for film blowing, injection molding, etc.)

- Production Capacity: 100-500KG/H, support for customization.

Plastic Pelletizing Machine | Plastic Recycling Process

| Plastic Recycling Plant

- Applicable Raw Materials: HDPE bottles, food containers, appliance shells, trash cans, plastic barrels, plastic containers, battery cases, and various injection-moulded hard plastic materials or products.

- Plastic Material: PP, PE, ABS, PVC, PS

- Final Product: Uniform plastic granules for reprocessing or reuse.

- Plastic Granulation Process: Crushing-Washing-Dewatering-Pelletizing-Cooling-Pellet cutting.

PET Bottle Recycling Machine | PET Recycling Line

- Applicable Raw Materials: Various types of PET bottles, including mineral water bottles, carbonated drink bottles, juice bottles, liquor bottles, dairy beverage bottles, and edible oil bottles (PET material).

- Recycling Type: Post-consumer recycling, In-house recycling

- Final Product: Clean PET flakes (rPET), suitable for pelletizing, bottle-to-bottle recycling, and polyester filament production

- Process: Label removal → Crushing → Bottle cap and flake separation → Hot washing → Friction washing → Rinsing → Drying

- Capacity: 500–6000 kg/h, meeting the production needs of various PET bottle recycling plants.

Styrofoam Recycling Machine | Foam Recycling Machine

- Applicable Raw Materials: EPE foam sheets and rolls, EPE protective foam, fruit nets, pearl cotton, EPS foam boards, EPS foam packaging from electronics and appliances, Foam boxes and foam trays, etc.

- Process: Compression, crushing → melting → Extrusion → Pelletizing.

- Final product: Recycled pellets, suitable for producing new foam products or plastic items.

- Capacity: 100-200KG/H

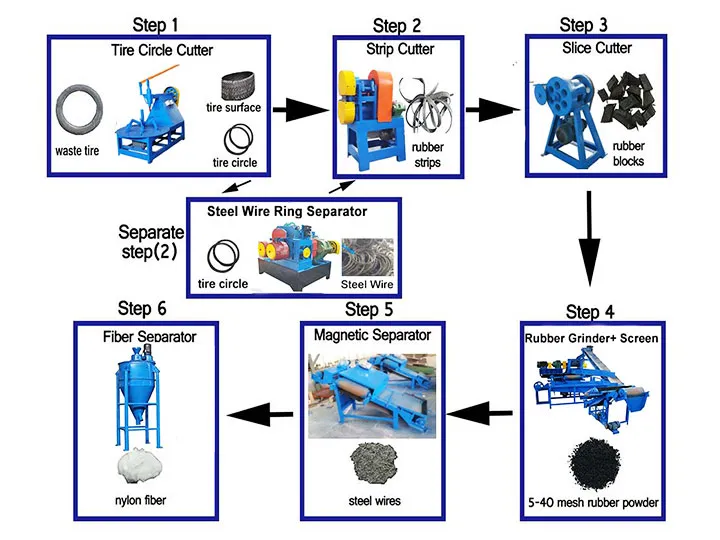

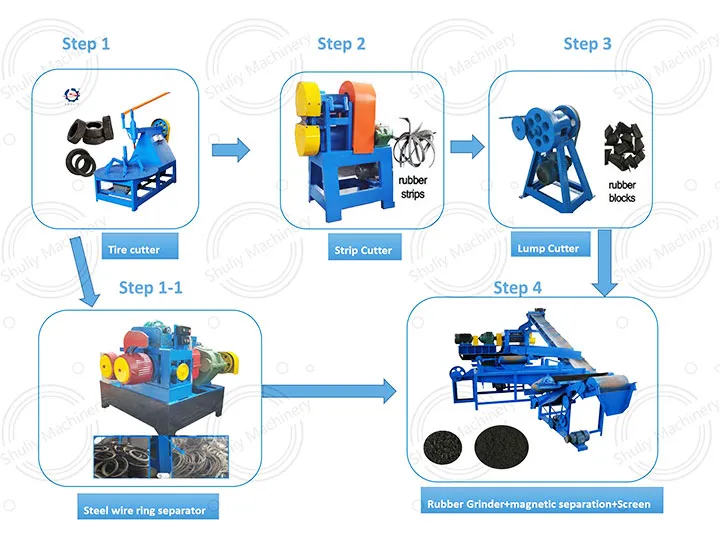

Rubber Powder Production Line | Tire Recycling Machine

- Tyre types handled: Passenger car tires, light truck tires, medium truck tires, and bus tires, as well as OTR tires such as mining vehicle tires, large loader tires, and bulldozer tires.

- Production Line Solutions: semi-automatic rubber powder production line, automatic tyre recycling line, OTR waste tyre recycling plant.

- Final Product: Rubber powder, rubber granules, steel wires.

- Related Machines: tire sidewall cutter, tyre strip cutting machine, tire block cutter, tyre wire removal machine, tire debeader, tire dismantling machine, tire shredder, rubber cracker mill.

Egg Tray Production Line | Paper Tray Making Machine

- Applicable Raw Materials: Old newspapers, used book paper, corrugated cartons, waste cardboard, office waste paper, paper trimming scraps, and waste pulp boards.

- Process: Pulping → egg tray molding → drying system → hot pressing → packing.

- Final product: Egg trays (30-cell, 20-cell, 10-cell, and other specifications), egg cartons, fruit trays (apple trays, pear trays, peach trays), industrial packaging trays (appliance packaging trays, electronic product inlays), food service trays (disposable paper plates, coffee cup holders), and agricultural trays (seedling trays, nursery cups), etc.

- Capacity: 1000-8000pcs/h

Hot Product-Start Your Plastic Recycling Business

We provide professional, high-efficiency single plastic recycling machines and solutions tailored to your specific raw materials. Here we present the key machines commonly used in the recycling of plastic films, rigid plastics, PET bottles, and foam materials, helping you quickly understand the equipment configurations required for different recycling solutions.

Whether shredding, washing, or pelletizing, we provide the right machines for plastic film recycling.

- Plastic Film Shredder: Shreds plastic film into small pieces.

- Washing Tank: Removes dirt and impurities.

- Plastic Dewatering Machine: Dries the material.

- Plastic Film Granulator: Melts and extrudes cleaned plastic film into continuous strands.

- Cooling Tank: Cools the plastic strands.

- Pellet Cutting Machine: Cuts strands into uniform pellets.

For buckets, pipes, HDPE bottles, and other rigid plastics, machines are designed based on material type.

- Hard Plastic Shredder: Crushes rigid plastic, sieve size customizable.

- Washing Tank: Removes dirt and impurities.

- Plastic Dewatering Machine: : Efficiently removes moisture.

- HDPE Granules Making Machine:: Special feeding design ensures smooth pelletizing.

- Cooling Tank: Cools the plastic strands.

- Pellet Cutting Machine: Cuts strands into uniform pellets.

A complete solution to process waste PET bottles into high-quality PET flakes.

- PET Bottle Label Removing Machine: Removes bottle labels.

- Plastic Bottle Shredder: Crushes PET bottles.

- Sink Float Plastic Separation: Separates caps and labels from flakes.

- PET Flakes Hot Washing Machine: Cleans glue and oil residues.

- Friction Washer: Deep cleans flakes.

- Dewatering Machine: Dries the flakes.

- Air Separator: Removes light impurities.

- Plastic Bottle Baling Machine: Compress and bundle plastic bottles.

Different solutions based on your raw material and processing method.

Tire Recycling Solutions for Your Business

We offer a variety of tire recycling solutions, introducing each machine within production lines. Every tire recycling machine can be used independently or combined into a complete waste tire recycling plant, and configurations can be tailored to your needs.

Three solutions are available for different capacities:

Specially designed for large OTR (Off-The-Road) tires, with larger tire shredders and rubber cracker mills:

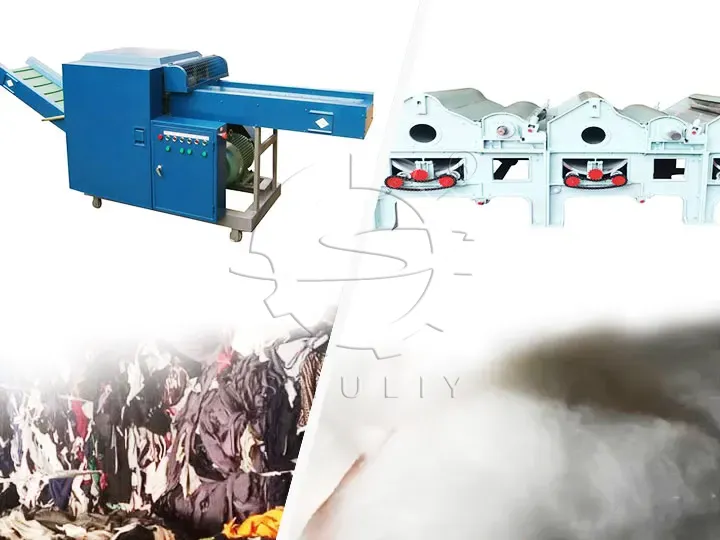

Other Recycling Equipment: Paper, Fiber, Metal

In addition to plastic and tire recycling machines, we also offer a wide range of solutions for paper, fiber, and metal recycling. Each machine can be used independently or integrated into a production line to achieve efficient recycling and reuse.

Ideal for recycling waste paper into pulp and forming paper trays such as egg trays.

- Pulping Machine: Converts waste paper into pulp.

- Egg Tray Forming Machine: Forms pulp into egg trays or paper trays.

- Drying System: Dries the wet trays after forming.

- Hot Press Machine: Increases the strength and smoothness of the trays through high-temperature pressing.

- Packing System: Packs finished trays for storage and transport.

- Cardboard Shredder: Cuts cardboard into mesh or shredded materials for packaging.

Designed for recycling waste fiber to improve reuse efficiency.

Efficiently processes various scrap metals for recycling.

Case & News

Why Choose Us?

Every client’s material and capacity needs are different. We provide fully customized machinery configurations to fit your exact requirements.

From plastic to tires, paper, metals, and fibers—we offer complete recycling systems across multiple industries, all in one place.

Using high-quality materials and advanced manufacturing processes, our machines ensure high-efficiency operation, low failure rates, and long service life.

We’re not just a supplier—we’re your partner. From pre-sale consultation to installation, training, and after-sales service, we support your business growth at every stage.