The PET plastic crusher is one of the important equipment for plastic bottle recycling lines, which can efficiently crush waste plastic bottles and break them into uniform-size PET flakes. In plastic bottle recycling, this step is very important because plastic bottles are large and not easy to recycle directly. The shredded plastic facilitates further recycling and transportation of the material.

We have a wide range of PET bottle crusher machines with different models, outputs, or appearances for you to choose from, and we can also customize them according to your requirements. If you want to get a reasonable quotation, you can leave a message on our website.

Introduction of PET Plastic Crusher

A PET Plastic crusher is a machine that crushes plastic bottles and other waste plastics into pieces. Shuliy’s plastic bottle crusher is uniquely designed and precisely manufactured to effectively crush waste pet bottles. We have many models for you to choose from.

You can choose to use the machine alone or form a PET bottle washing line with a PET label remover machine, PET bottle flakes washing machine, a hot washing tank, etc., thus greatly improving production efficiency.

Features of PET Bottle Crushing Machine

- The PET bottle crushing machine can be filled with water to crush the plastic bottles while washing.

- The PET bottle shredder is made of alloy steel with high material hardness and durability.

- The output of the shredder also depends on the size of the screen, which ranges from 14-18mm for plastic shredders.

- The number of movable and fixed knives in the PET plastic crusher varies depending on the model.

Raw Materials and Final Products of PET Plastic Crusher

The recycled plastic bottles are first flattened and packed, which makes them easier to transport, and then the flattened drink bottles are passed through a PET plastic crusher and turned into small pieces of plastic.

The plastic is then washed to remove any dirt, labels, dirt, etc., and the final product is a clean shard. The pieces can then be further processed into plastic pellets, which can be used as raw materials to produce new plastic products.

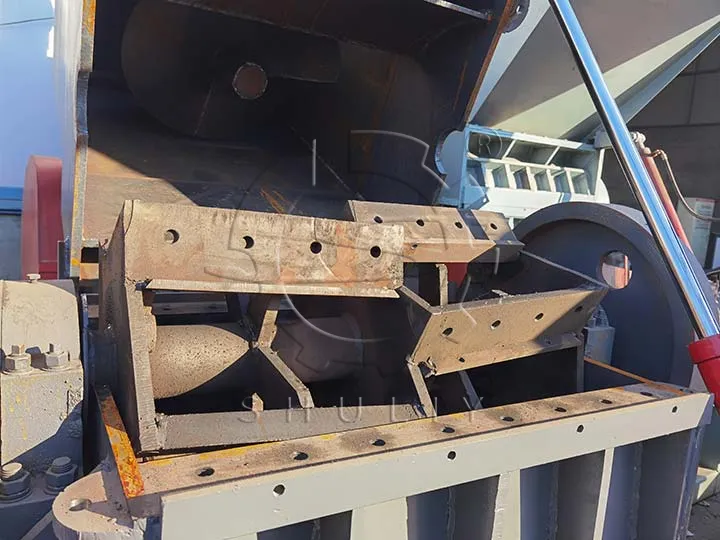

Working Principle of Plastic Bottle Crusher

There are fixed and moving knives inside the PET bottle crushing machine. The plastic bottle enters the crusher and is cut according to the angle formed between the fixed knife and the moving knife.

Video of PET Bottle Crushing Machine

Parameters of PET Plastic Crusher

| Model | SL-60 | SL-80 | SL-100 | SL-120 |

| Height (m) | 1.8 | 2.6 | 2.6 | 2.6 |

| Capacity (kg/h) | 500 | 1000 | 1500 | 3000 |

| Motor (kW) | 22 | 37 | 75 | 90 |

| Thickness of the knife (mm) | 30 | 40 | 40 | 40 |

| Plate thickness (mm) | 16 | 20 | 30 | 30 |

Global Cases of Plastic Bottle Shredder

PET Bottle Crusher Machine Sent To Nigeria

Shuliy Machinery recently customized a PET bottle washing line for a customer in Nigeria, the equipment includes a PET label remover machine, a PET bottle crusher machine, several PET bottle flakes washing machines, and so on.

Plastic Bottle Shredder Shipped To Saudi Arabia

Saudi Arabian customers bought PET bottle recycling machines such as a plastic bottle shredder and PET bottle flakes washing machine in our company, which is a customized production line for this customer, with an output of 1000kg/h. According to the customer’s raw material is dirty and old, it is equipped with three sink float separation tanks.

Machine Maintenance of PET Bottle Crushing Machine

To prolong the life and efficiency of the blades, the shredder blades should be sharpened for 2 to 3 days or 20 tons of work. The service life of a set of blades is 3 to 4 months. Shuliy Machinery can be equipped with a knife sharpening machine according to your requirements.

Get In Touch With Us For A Quote!

If you have a large number of PET bottles that you want to recycle, or you are planning to start a PET bottle recycling business, we can provide you with the most suitable PET bottle recycling machine. You can leave a message on our website and our professional team will give you the most affordable and reasonable offer!