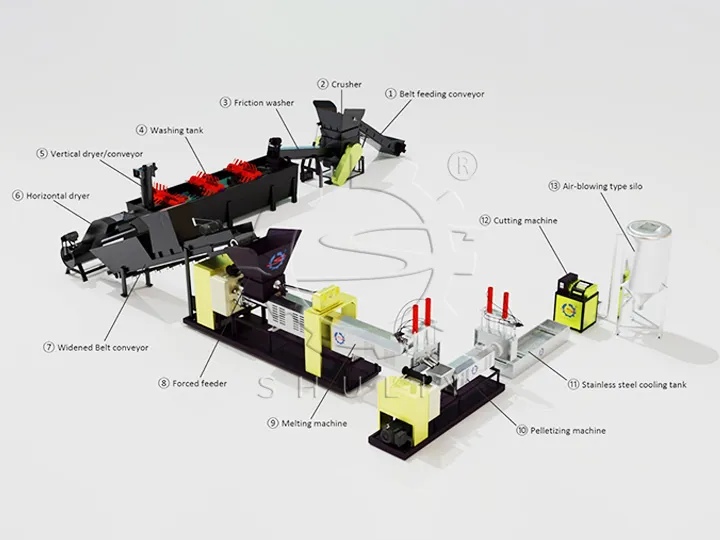

This PP PE flake recycling line is mainly used for the recycling and pelletizing of hard waste plastics. The equipment of this plastic pelletizing line includes a waste plastic crushing machine, plastic scrap washing machine, horizontal dryer, plastic pellet machine, plastic Dana cutter, etc.

Shuliy Group can match different plastic waste recycling machines according to customers’ different production needs, applications, and raw materials, and help customers design their plants and reasonably arrange their machine displays. Below we will detail how to process waste plastics into recycled granules.

Advantages of Our Granulation Units

- Excellent pellet quality, uniform size, stable performance, suitable for reproduction.

- The design of our granulation line is flexible, and the layout of the line can be customized according to customer needs to optimize space utilization.

- The equipment is optimized for high productivity.

- Provide customers with perfect pre-sale, sale, and after-sale service, including equipment installation, debugging, training, and so on.

Working Video of Plastic Pelletizing Line

The video below is a feedback video given to us by Côte d’Ivoire, who wants to recycle HDPE bottles into pellets. Our plastic recycling machine can also recycle PP PVC ABS PS and other waste plastics.

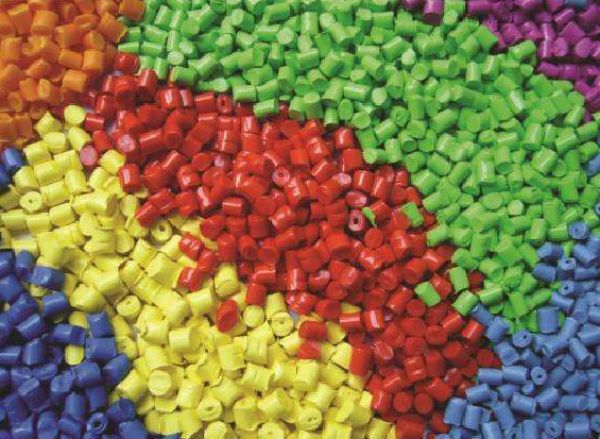

Raw Materials and Final Products

The PP PE flake recycling line is dedicated to recycling hard plastics such as plastic drums, PP disposable cups, food containers, appliance shells, plastic tubs, plastic boxes, plastic flakes, etc. This plastic waste recycling plant recycles plastic waste into recycled plastic pellets.

Plastic Granulation Process

Plastic pelletizing process is the process of converting waste plastics into reusable plastic pellets. It generally consists of the following steps:

- Crushing: Crushing waste plastics into small pieces for subsequent processing.

- Washing: Remove impurities, oils, etc. from the plastic pieces to ensure the purity of the raw material.

- Drying: The cleaned plastic pieces are dried to remove moisture in preparation for subsequent melting.

- Strip pelletizing: The dried plastic is fed into the extruder, heated and melted, and then extruded and molded into plastic strips.

- Cooling: Plastic strips need to be cooled to allow them to cure and mold.

- Cutting pellets: The cooled plastic strip is further cut into small pellets.

- Storage or packing: Store or package cut plastic granules for transportation and use.

3D Video of Plastic Pelletizing Line

Related Equipment for PP PE Flake Recycling Line

Conveyor: Conveyor PP PE materials into the waste plastic crushing machine.

Plastic crusher: The crusher plastic machine crushes PP PE waste plastic into small pieces.

Water can be added during the crushing process, which can play the role of cleaning friction while crushing plastic, and at the same time, it can reduce tool wear and extend the service life of the blade. So this waste plastic crushing machine has been praised and recognized by foreign customers.

Rinsing tank: The rinsing tank is made of stainless steel and is used to clean the crushed material. The plastic scrap washing machine has many teeth plates that force the plastic pieces forward.

Horizontal dryer: The horizontal dewatering machine is specially designed for dewatering hard plastic chips.

High-speed centrifugal dehydration, automatic discharge, dehydration rate of more than 98%, and a very high degree of automation.

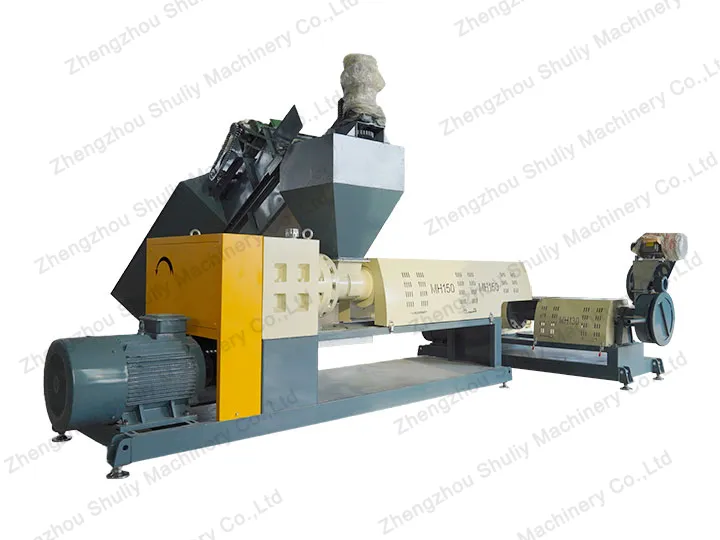

Plastic Pelletizing Machine: This machine is used to melt the plastic pieces and extrude them into strips.

The plastic pellet machine is the most central equipment in the PP PE flake recycling line. The dehydrated plastic pieces enter the main machine of the granulator to be heated and melted, and the melted plastic is extruded into strips through the mold head in the auxiliary machine.

Cooling Tank: The cooling tank is made of stainless steel and is used to cool and harden the soft strip plastic extruded from the plastic granules making machine.

Pellet Cutting Machine: This machine is used to cut the cooled plastic strips into plastic granules.

The plastic Dana cutter adopts high-speed rotating blades, which can achieve efficient cutting, a high degree of automation, adjustable cutting size to meet the needs of different customers, a simple overall structure, and easy maintenance.

Storage Bin: The storage bin is made of stainless steel for the final bagging of plastic pellets. The elevated bin can reduce floor space and save labor. The size of the plastic granule storage silo can be customized according to the customer’s requirement, and the size is optional.

Parameters of The Extrusion Line

| Capacity | 100-500kg/h |

| Applicable materials | Plastic drums, PP disposable cups, food containers, appliance shells, plastic tubs, plastic boxes, plastic flakes, etc. |

| End product | Plastic granules |

| Plastic pellet size | About 3mm |

| Auxiliary equipment | Strip blowing machine, strip shaking machine, vibrating screen |

| Delivery date | 20-25 days |

| Installation | Online or on-site assistance |

| Warranty period | 1 year |

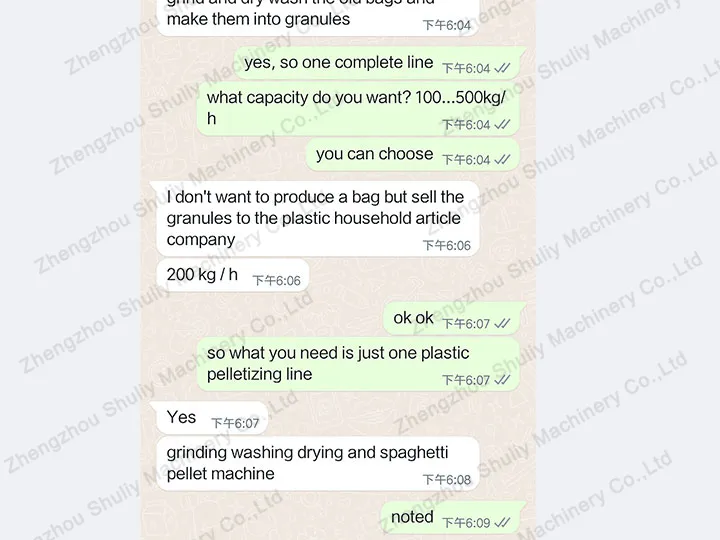

Successful Cases of PP PE Flake Recycling Line

Plastic Waste Recycling Plant Shipped to Côte d’Ivoire

This customer from Côte d’Ivoire is an old customer of ours, and this time he plans to purchase a brand new plastic waste recycling plant. Out of recognition for us, the customer chose us again.

After detailed communication and negotiation, Shuliy successfully reached a transaction agreement with the client. At present, the machine has been successfully delivered to Côte d’Ivoire.

More details: Plastic Flake Pelletizing Line Solutions Shipped to Côte d’Ivoire

Two Plastic Pelletizing Lines Sent to Ethiopia

Ethiopian customers have ordered these two plastic pelletizing lines for crushing and granulation of LDPE and HDPE plastics, respectively. Here is the shipping video we took for the customer.

Applications of Recycled Plastic Pellets

Plastic waste is everywhere in daily life. It can be made into pellets, recycled and reused, and applied in various aspects of life.

But the application areas are different. For example, convenience bags made from recycled granules cannot be used for food packaging, while some pellets processed from PVC may contain toxins themselves, so there will be restrictions on their application.

Generally speaking, primary and secondary materials can be used for film blowing, wire drawing, etc., while tertiary materials can only be used for injection molding. Using recycled materials to make plastic products saves resources and reduces solid waste pollution.

Factory Display of Plastic Recycling Machine Plant