The EPE foam pelletizing machine is equipment that heats and melts EPE foam material and extrudes it into pellets. The processed recycled EPE plastic granules can be recycled and reused. It has the characteristics of high output, low noise, stable performance, and easy operation.

Our EPE pelletizing machines can be customized in terms of model and output according to the specific needs of our customers. We offer a wide range of models of EPE granulators to meet the needs of different sizes and application scenarios.

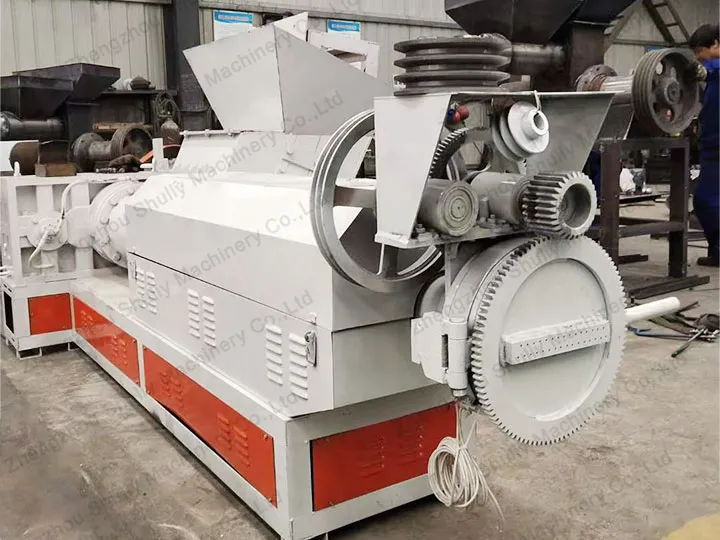

Introduction of EPE Styrofoam Pelletizing Machine

EPE styrofoam pelletizing machine is designed for the recycling and processing of Expanded Polyethylene (EPE) waste. Through a highly efficient extrusion and pelletizing process, this machine can convert waste EPE foam into uniform, high-quality recycled pellets with an output of up to 150-200kg per hour.

It not only helps to reduce the production cost but also effectively reduces the accumulation of waste materials and realizes the recycling of resources. It is suitable for the recycled manufacturing of packaging materials, fillers, and insulation materials, and is ideal for enhancing the recycling efficiency of enterprises.

Features of EPE Foam Granulator

- Integrated Crushing and Feeding System – The machine comes with a built-in crusher for efficient material processing.

- High Production Capacity – Capable of producing 150-200kg/h of recycled granules.

- Energy Efficient – Designed for low power consumption while maintaining high efficiency.

- Stable Performance – Ensures consistent output quality with advanced extrusion technology.

- Versatile Application – Suitable for recycling various EPE foam waste into reusable granules.

Applications for EPE Foam Pelletizing Machine

EPE, also known as pearl cotton, is a new type of environmentally friendly packaging material. Due to its better performance, lower cost, beautiful appearance, and better effect compared to traditional materials, EPE pearl cotton has been widely used in various industries. EPE is an environmentally friendly packaging material that not only does not pollute the environment but can also be recycled and reused.

An EPE foam pelletizing machine is a special machine for crushing and granulating waste EPE foam such as used pearl cotton, pearl cotton scraps, recycled pearl cotton products, used crawl mats, etc.

Working Principle of EPE Foam Granule Machine

Feeding and cutting: The waste EPE material is first fed into the feeding system of the EPE foam granule machine. Due to the softness of the EPE material, the feeding system is equipped with a cutting device that cuts large pieces of EPE material into appropriately sized fragments.

Heating and melting: The cut EPE pieces enter the heating zone through the screw extrusion system. The temperature in the heating zone is controlled by heating and gradually increases to melt the EPE material.

Extrusion: The molten EPE material is pushed by the screw and extruded through the die to form a continuous plastic strip.

Final Recycled EPE Pellets

EPE Styrofoam Pelletizing Machine Details

The EPE granulator consists of a feeder, a control cabinet, a heating device, a motor, a die head, etc. The set is well-supported and can be produced automatically and continuously.

Our hot model SL-160, machine size 3400*2100*1600mm, inlet size 780*780mm, power 30kw, capacity 150-200kg per hour, heated by the heating ring.

EPE Foam Granulator Export Case

Recently, we exported an EPE foam granulator to a customer in Suriname. The customer plans to process collected waste foam into reusable granules. With a production capacity of 150-200kg/h, this machine will help improve recycling efficiency and reduce material waste. The equipment has already been shipped to the customer’s factory in Suriname, where it will soon be put into operation.

For more details, you can click on this article to view: Foam Granulator Aids Suriname in EPE and EPS Recycling

Recommend Plastic Strip Cutting Machine

The EPE foam pelletizing machine and plastic strip cutting machine are often used in combination. The granulator melts the foam by heating it and extruding it into strips. The plastic strip cutting machine cuts the long strips of plastic into granules for storage and reuse.