Shuliy Machinery’s PET bottle washing plant is ideal for kick-starting the plastic bottle recycling business. This highly efficient machine processes baled PET bottles and converts them into non-polluting PET flakes. These high-quality plastic flakes can be sold to polyester staple fiber manufacturers, thereby realizing significant revenues.

The production capacity of this PET bottle cold washing line is 500kg/h-6000kg/h. Depending on your specific needs, we can also design and supply customized set-ups with additional machinery and increased capacity to ensure that our PET bottle washing plant perfectly meets your production requirements.

PET Bottle Recycling Machine Application Areas

PET bottle washing plant is mainly used for recycling PET bottles such as carbonated beverage bottles, mineral water bottles, fruit juice bottles, food bottles, cleaning products bottles, and so on. Finally, you will get clean PET bottle flakes. Washed PET bottle flakes can be used as a high-quality recycled plastic raw material for the manufacture of new bottles, plastic sheets, fiber products, and other plastic products.

Shuliy Machinery’s PET recycling machine is the ideal solution for processing discarded PET bottles into PET flakes. By utilizing our high-tech plastic recycling machinery, the produced PET flakes not only maintain a high level of cleanliness but are also entirely free from contamination.

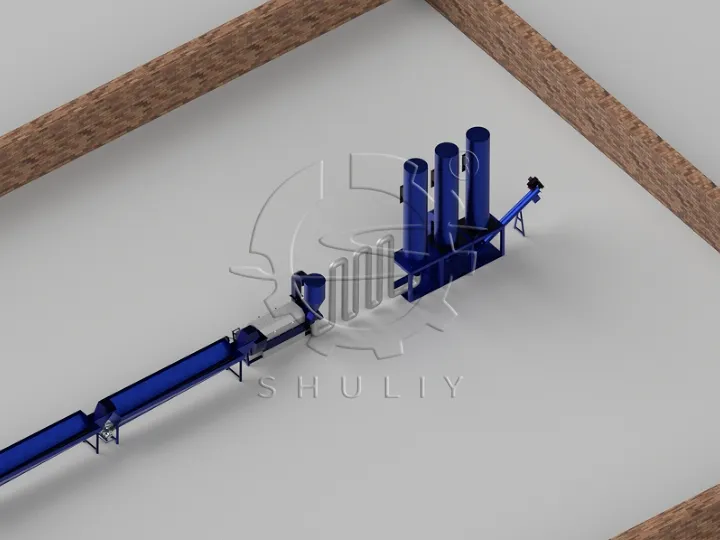

PET Bottle Washing Plant Description

PET cold washing line is a kind of production line equipment specialized in cleaning waste PET bottles, mainly through cold water washing to remove the impurities and pollutants on the surface of bottles. The entire cold-washing process does not involve a heating step and relies on strong friction and multiple rinsing to ensure the cleanliness of the bottle flakes.

The PET bottle washing plant usually includes a label remover machine, a PET crusher, a friction washer, a plastic float sink tank, a centrifugal dewatering machine, and other equipment. Through this cold washing method, glue, labels, and other contaminants can be effectively removed from PET bottles, providing high-quality raw materials for subsequent recycling or granulation.

Working Process of PET Recycling Plant

The workflow of the PET flakes washing line consists of several steps to ensure that waste PET bottles are thoroughly cleaned and efficiently processed. First, the waste PET bottles are fed into the label remover machine through a conveyor belt to remove the labels from the bottles.

Next, the bottles enter the PET bottle crusher and are crushed into small bottle flakes. Bottle flakes then enter the plastic float sink tank for initial cleaning in cold water to remove surface impurities and dirt.

After cold washing, the bottle flakes are passed through a friction washer for further cleaning to ensure that residual contaminants are thoroughly removed.

Finally, the cleaned bottle flakes are dewatered through a centrifugal dewatering machine and then enter the packaging process to become clean, uniform, high-quality finished PET bottle flakes.

Video of PET Bottle Washing Plant

Introduction of PET Bottle Cold Washing Line Machines

Bale opener: Used to break up hydraulically baled PET bottle bricks and place them on a conveyor belt. This machine is suitable for washing lines of 1000kg/h or more.

Tumbler screen: Suitable for large output PET bottle washing plants, its function is to separate PET bottles from stones, metals, and impurities by rotating. To improve the quality and purity of recycled PET bottle flakes.

Label removing machine: It is designed to remove PVC labels from PET bottles with a de-labeling rate of over 98%. In the case of flattened bottles, the de-labeling rate is more than 95%.

The machine can effectively reduce the PVC content to less than or equal to 100-300mg /kg.

Automatic plastic bottle crusher: This plastic recycling machine is used to crush PET bottles into PET flakes.

The blade material of this machine is 9CrSi and the screen size is 16-18mm, which is adjustable.

Sink float separation tank: This plastic recycling machine is used to separate PET flakes from PP/PE bottle caps. During the cleaning process, PET plastics sink while PVC labels and PP/PE bottle caps float. The machine can control polyolefin content ≤200-300(mg/kg).

Friction washer machine: Friction washing utilizes the friction generated at high speeds between PET flakes to effectively clean debris. The machine is usually placed at 45 degrees to facilitate better drainage.

Horizontal dryer: Dehydrators use centrifugal force to shake off water from PET flakes. The drying degree of this machine can reach 95-98%.

PET Bottle Recycling Machine Features

- The high level of automation reduces your labor costs and guarantees a high processing capacity: 500-6000 kg/h.

- The whole plastic bottle recycling plant can be designed to suit the dirtiness of the flakes and ensure the quality of the final product.

- If your waste plastic bottles are dirty and have a lot of adhesive or oil on the surface, we offer you a PET bottle hot washing line, which can effectively remove the oil or adhesive.

- Supports multiple washings to ensure the purity of PET bottle pellets to produce high-quality recycled bottle flakes.

- Easy to install and maintain, and can be expanded and customized to meet production needs.

Parameters of PET Bottle Washing Plant

Production Capacity

Standard output ranges from 500kg/h – 3000kg/h and can be customized according to customer requirements.

Configurations

- The main equipment includes a PET bottle label remover, PET crushing machine, sink float separation tank, friction washing machine, dewatering machine, and so on.

- Optional equipment: bale opener, tumbler screen, drying pipe, winnowing machine, etc.

Raw Materials and Finished Products

- The PET bottle washing plant can recycle all kinds of PET bottles such as carbonated beverage bottles, mineral water bottles, juice bottles, and so on.

- The finished product is clean, unadulterated recycled PET bottle flakes. The finished bottle flakes can be directly used in the production of recycled PET products, such as textiles, packaging materials, building materials, and so on.

Warranty Period

The equipment warranty period is one year, providing lifelong technical support and after-sales service.

Equipment Installation

Provide detailed installation guides and operation manuals, and dispatch technicians to the site for installation guidance and operation training if necessary.

Delivery Date

The usual delivery date is 30-60 days after signing the contract, depending on the customer’s demand and the quantity of equipment.

PET Bottle Cold Washing Line Sent to Congo

Our customer from Congo plans to open a PET bottle washing plant, and after careful communication and inspection, they purchased a complete PET bottle cold washing line from Shuliy.

Plastic Bottle Washing Line Installation Project in Nigeria

The Nigerian customer purchased two plastic recycling lines from Shuliy Machinery, one of them is a plastic bottle recycling plant, which has been running successfully with the assistance of our engineers in installation.

Related PET Bottle Washing line

You can also choose our plastic bottle hot washing line if you have dirty raw materials or want a cleaner end product. This PET bottle washing plant returns to a hot washing tank that removes stains that are difficult to remove with cold washing.

PET Bottle Washing Machine Price

Shuliy Machinery is a PET bottle recycling machine manufacturer. Our plastic bottle recycling plant has been well received by many customers, and we give you the opportunity to improve the highest quality PET bottle recycling machinery at an affordable price so that you can operate your PET bottle washing plant successfully.

Please contact us to discuss the PET bottle washing machine price and ordering details.