The plastic film granulator is an efficient plastic waste regeneration equipment, specialized in converting all kinds of plastic waste, such as plastic bags, woven bags, agricultural films, raffia grass, etc., into high-quality plastic granules. Its core process and structural composition ensure a stable production process and high-quality finished products.

We have different models and outputs of granulators for plastics to meet the different needs of different customers, and we can also customize complete solutions according to requirements. Leave the raw materials you want to process on our website and we will recommend the right plastic recycling machine for you.

What are the Raw Materials of Plastic Film Granulators?

Our plastic film pelletizing machine is specially designed for processing PP and PE materials, including plastic bags, woven bags, agricultural films, raffia bags, and so on. All of them are reliably processed in our plastic film recycling machine, which converts them into useful recycled plastic pellets.

Process and Structure of Plastic Film Pelletizing Machine

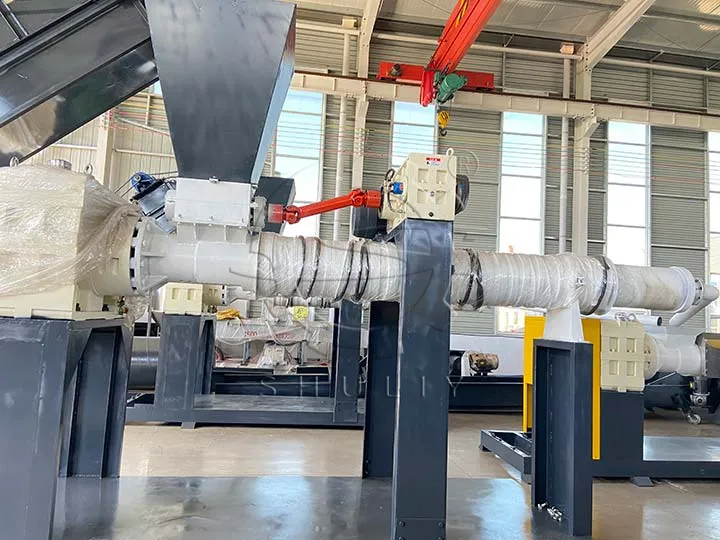

The plastic film recycling machine employs some key components for an efficient plastic waste regeneration process. It includes components such as the feeder, automatic feeder, reducer, heating device, screw, motor, and die head.

The automatic feeder ensures a smooth supply of material, the heating device is used to heat and melt the material, and the gearbox and motor work in tandem to power the screw, which pushes the material forward and finally extrudes it through the die head.

Video of Plastic Granules Machine

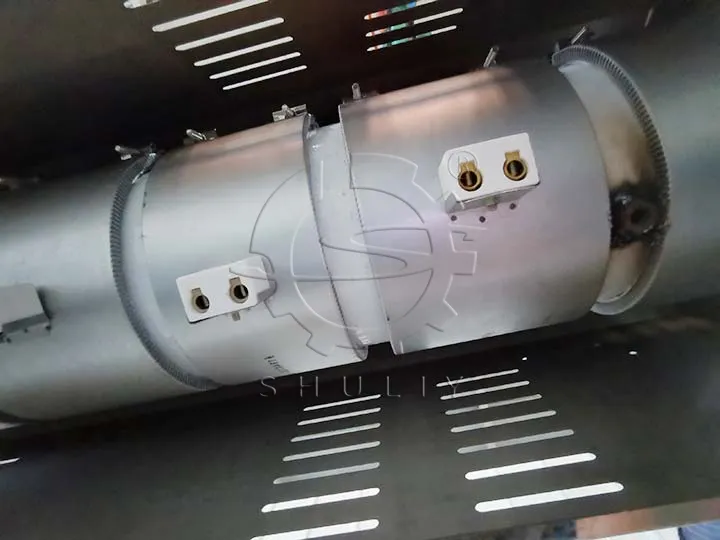

Heating Device of the Plastic Film Granulator

Electromagnetic heating: The most effective and longest-lasting heating method.

Ceramic heating: It is also the heating method chosen by most customers. Ceramic heating elements provide even heating distribution, ensuring that raw materials are heated evenly during processing.

Recommended Related Equipment

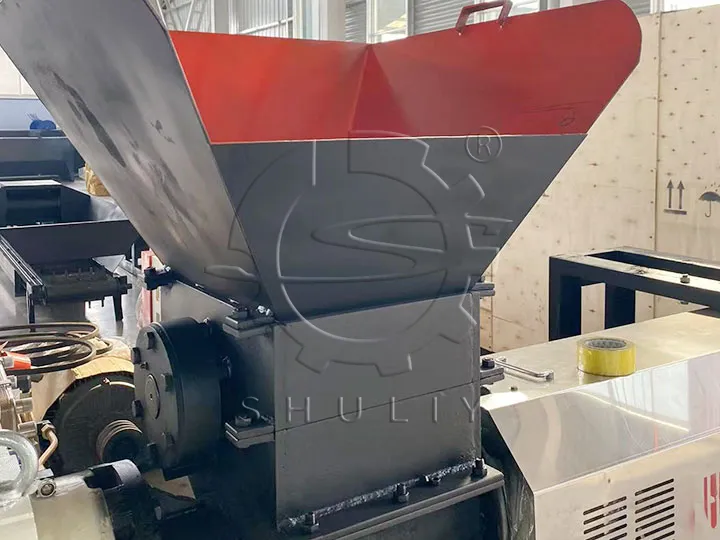

Automatic Feeding Machine

The function of a force feeder is to feed raw materials in a uniform and continuous manner into plastic film granulators. It ensures that the raw materials can be maintained in a stable supply during processing through a special structure and control system, thus avoiding possible problems of poor material flow, build-up, or intermittent supply.

This helps to maintain the continuity and stability of the production process, improve production efficiency, and ensure uniform and consistent quality of the finished product.

Plastic Film Crusher

The plastic film crusher, also known as a plastic bag crusher machine, is a specialized equipment whose main function is to crush plastic film and decompose it into fragments.

This type of machine is usually used in plastic recycling granulating lines, mainly used to treat waste plastic films, to facilitate the subsequent processing of these waste plastics and conversion into recycled plastic pellets.

FAQs of Plastic Film Granulator

What Types of Plastic Waste Are This Machine Suitable For?

The plastic film pelletizing machine is suitable for the regeneration of various plastic waste materials such as plastic bags, woven bags, agricultural films, and Lafite straw bags.

How to Ensure The Stability of Plastic Pellets Quality?

By carefully designed die heads and heating systems, we ensure that the plastic is evenly heated and extruded during the processing, thereby ensuring the quality stability of the plastic granules.

How to Maintain And Clean The Plastic Film Recycling Machine?

Regularly cleaning screws die heads, and other components to ensure the internal cleanliness of the plastic film granulator helps maintain its normal operation.

What Is The Output of This Plastic Granules Machine?

The plastic film recycling machine can reach 100kg to 1000kg per hour. We can also customize the equipment with larger output according to the specific needs of customers to meet the requirements of different production scales.

Global Cases of Plastic Film Granulating Machine

Plastic Film Granulating Machine Sent To Sri Lanka

Customers from Sri Lanka chose Shuliy’s SL-180 plastic film granulating machine for processing waste PP PE film. Below is a picture we took of the machine for our customer before it was shipped.

Granulators For Plastics Sent To Ghana

Ghanaian customer chooses our plastic film granulator for processing waste plastics into plastic pellets for sale. This granulator for plastics is our new machine with a new appearance and better performance.

Shuliy Plastic Film Granulator for Sale

Shuliy Machinery is committed to providing you with high-quality and efficient plastic film recycling machines. If you are interested in our plastic recycling machines, please leave a message on our website or contact us through WhatsApp. We will provide you with details such as the plastic granulator price, pictures, and videos.