The plastic crusher can be applied in the waste plastic recycling industry, plastic molding and processing industry, etc. It is an important piece of equipment in the plastic recycling granulating line. Plastic waste shredder machines can crush all kinds of plastics made of PP, PE, HDPE, PVC, and ABS, such as plastic barrels, plastic baskets, plastic films, plastic toys, etc.

Shuliy Machinery is an experienced plastic shredder machine supplier, this plastic recycling shredder of ours has been well received by customers from many countries, including but not limited to Somalia, Nigeria, Cote d’Ivoire, Botswana, Ghana, Kenya, Mozambique, Saudi Arabia.

We can offer you a complete solution, a reasonable offer, and a caring after-sales service.

Plastic Recycling Shredder Application

Introduction of Plastic Crusher

It can crush all kinds of waste plastic products. The pellets can be directly extruded by a plastic pelletizer machine as a raw material for production.

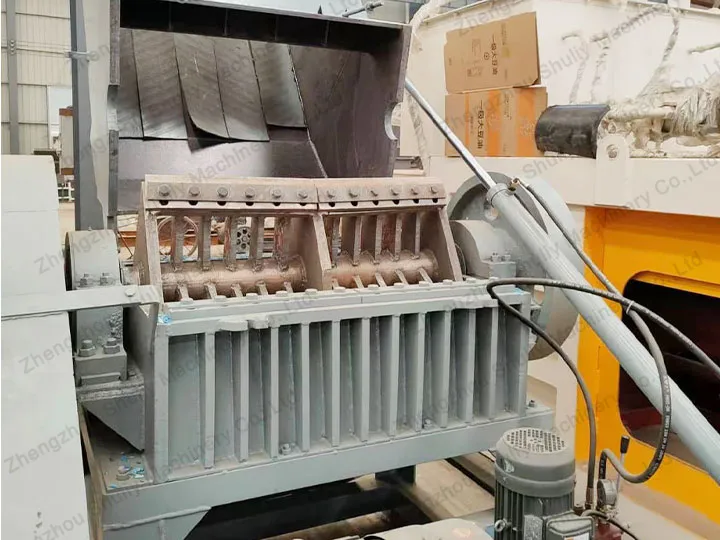

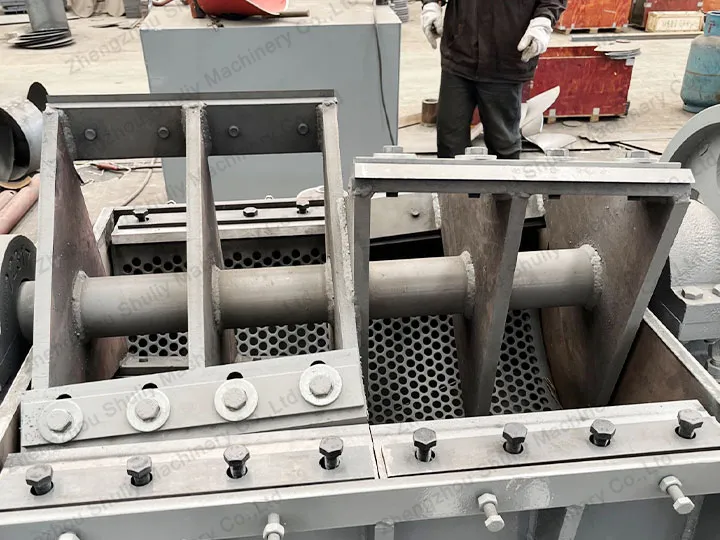

This equipment adopts an alloy steel blade, which has a long service life. At the same time, the plastic crusher adopts a separate design, which is easy to repair and clean, and has a double-layer structure.

It is equipped with sound insulation materials, and the noise is very low so the bearing rotates well for a long time. The drive equipment adopts a medium-speed motor, with low noise and low energy consumption. The motor is equipped with an overload protection device and a power supply chain protection system.

Raw Materials of Plastic Shredder For Recycling

The waste plastic crushers can be used to crush and recycle plastic pipes, plastic oil drums, paint drums, all kinds of plastic household garbage, plastic housings, drip irrigation tapes, shopping bags, agricultural films, used woven bags, and all other waste plastics.

Working Principle of Plastic Shredder Machine

When the plastic shredder machine is working, the motor drives the internal blades to rotate at high speed.

During the high-speed rotation of the moving and fixed knives, an angle is generated, and the blade that forms the angle will cut plastic, thereby crushing large pieces of plastic.

The crushed plastic fragments will be filtered through a sieve and output to the discharge port.

Features of Plastic Recycling Crusher

- Blades: HSS, Mn65, 9Crsi, SKD-11

- Compressive strength: >300MPA

- The distance between the moving knife and the screen is about 1.5-2cm, and the film material is close to 0 distance.

- The crushing process can be added to water, so that the plastic in the crushing plays a role in cleaning friction, and at the same time can reduce tool wear, extending the service life of the blade.

Parameters of Plastic Waste Shredder Machine

| Model | SLSP-600 | SLSP-800 | SLSP-1000 |

| Motor power | 30 kW | 45 kW | 55 kW |

| Capacity | 600-800kg/hour | 800-1000kg/h | 1000-1200kg/h |

| Material of knives | 60Si2Mn | 60Si2Mn | 60Si2Mn |

| Number of Knives | 10pcs | 10pcs | 10pcs |

| Box width | 600cm | 800cm | 1000cm |

How to Maintain the Plastic Recycling Crusher?

- After use, be sure to clean the plastic recycling crusher thoroughly to ensure that there are no residues inside or outside.

- Avoid impurities from entering the inside of the plastic shredder machine to prevent clogging and damage to the blades.

- Regularly check the lubrication of the plastic shredder machine to ensure that all moving parts are kept adequately lubricated to reduce friction and wear.

- Regularly check the blades for wear and tear, if you find that they are excessively worn or damaged, they need to be replaced promptly.

- Regularly check electrical wiring and connections to ensure there are no damaged or loose wires to prevent electrical failure.

Global Cases of Plastic Crusher

Shuliy plastic recycling equipment has been exported to many countries such as Ghana, Saudi Arabia, and Kenya. Customers find us through our website, and our sales manager will communicate with them to discuss various details of the machine. Customers have given us a lot of positive feedback after completing the installation, and quality and service are guaranteed.

Contact Us Now: Plastic Shredder Machine Supplier

Shuliy Machinery offers a wide range of plastic recycling shredders for a wide range of applications, which can shred all kinds of plastics with a full range of models. In most cases, this machine is the first step in recycling waste plastics.

As many wastes are recyclable, you may need subsequent equipment to reprocess them and then make more profit, such as plastic scrap washing machines, plastic scrap dryer machines, plastic granulators, and so on. You can view our case studies or send us a message now.