This plastic dryer machine is a device used to remove water from plastics in the recycling process. After washing, plastics usually contain a large amount of water and must be dewatered to ensure the quality and performance of the final product.

Waste plastics are washed during the recycling process, and inadequate drying may lead to quality problems such as bubbles, cracks, and discoloration in the product. Plastic scrap dryer machines are essential in waste plastic granulation lines and plastic recycling washing lines.

Advantages of Plastic Dryer Machine

The plastic dewatering machine separates water from plastic pellets or sheets by centrifugal force at high rotational speeds, ensuring that the plastic is dry and thus improving the efficiency of subsequent processing and product quality. The advantages of the centrifugal dryer are as follows:

- Efficient dewatering: Through high-speed rotation and centrifugal force, the plastic dewatering machine can quickly remove water from the plastic.

- High dewatering rate: the dewatering rate of the horizontal dewatering machine is up to 98%, and after adding a drying pipe, the moisture can be controlled at 0.5%-1%, which significantly improves the overall drying efficiency.

- Widely used: Suitable for dewatering of various plastic materials, such as PET bottle flakes, PE/PP films, hard plastic flakes, etc.

- Various dewatering machine options: Horizontal and vertical dewatering machines are available for different plastics, which can be used individually or in combination to flexibly respond to different production needs.

Working Principle of Plastic Scrap Dryer Machine

The plastic dryer machine quickly separates the water in plastic through the centrifugal force generated by high-speed rotation. After the material enters the dewatering machine, it is subject to the strong centrifugal force of the rotating cylinder, and the moisture is thrown out and discharged through the drainage port.

Applications of Plastic Chips Dryer Machine

This plastic dryer machine has a wide range of applications and can be used in production lines such as plastic recycling granulating lines and PET bottle washing lines, and is suitable for drying a wide range of plastics such as PP, LDPE, HDPE, PVC, ABS, PS, and PET.

Plastic Dryer Machine Parameters

The hot mode of the plastic dehydrator model is SL-550, and its specific parameters are as follows:

- Outer diameter: 550 mm

- Length: 1000 mm

- Filter aperture: 4 mm

- Processing capacity: 1000kg/hour

- Dehydration rate: 98%-99%

- Drying pipe: the material of the contact material part is 304 stainless steel, controlling the moisture to less than or equal to 0.5%-1%.

In addition to this, we have other models to adapt to various output needs and can also be customized according to customer requirements.

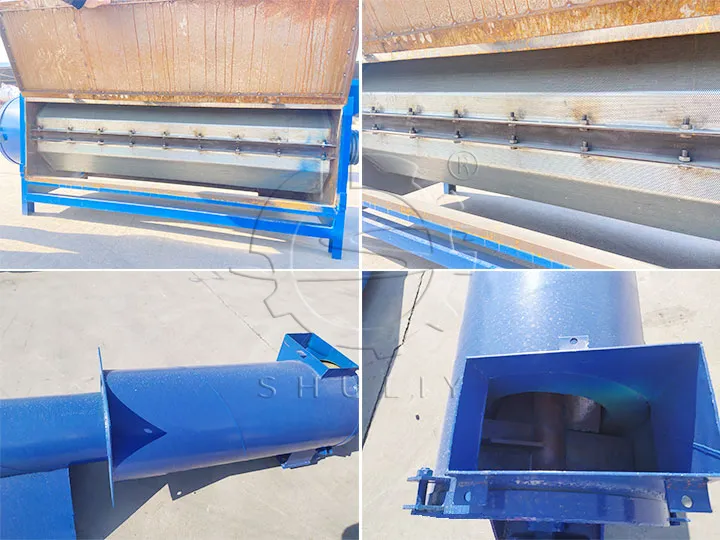

Two Types of Plastic Dryer Machine From Shuliy

Vertical Dewatering Machine

The vertical dewatering machine is widely used for lifting all kinds of plastic films, waste woven bags, agricultural films, plastic bags, and other materials from the plastic washing tank. It is usually installed at the end of the plastic rinsing tank and is mainly used in the production process such as plastic film granulation line.

Horizontal Dewatering Machine

The horizontal dryer is usually used in waste plastic granulation lines for hard plastic and PET washing plants, the materials that can be processed are waste plastic drums, plastic toys, plastic baskets, PET bottles, and so on. The machine adopts cyclone discharge, which serves to decelerate the speed and prevent the material from splashing out and injuring people.

Successful Cases Of Plastic Dewatering Machine

PET Flakes Dryer Machine Sent To Nigeria

The Nigerian customer chose a complete PET bottle washing recycling line, equipped with a wind separator after the PET flakes dryer machine according to the customer’s requirements.

Plastic Flake Dewatering Machine Shipped To Indonesia

Indonesian customers chose our plastic flake dewatering machine. The material to be dewatered by the customer was 1cm sized LDPE flakes and the customer wanted to dewater the material to a moisture content of less than 0.5%. We customized the screen size of the dewatering machine to prevent leakage and equipped it with drying pipes according to their specific requirements.

Technical Support From Shuliy

If you encounter any problems with the use, Shuliy Machinery will provide you with technical support. Whether it is the operation, maintenance, or troubleshooting of your equipment, our professional team is always ready to help you. With years of experience and expertise, we ensure that your plastic dryer is always in top condition.

If you are interested in our high-efficiency plastic dryer machine, please feel free to contact us. You can also leave a message on our website to express your interest and questions. We will reply to you as soon as possible with the information you need.