With the increasing development of the modern recycling industry, Shuliy Machinery provides personalized service based on the actual needs of customers and customizes integrated plastic washing and pelletizing solutions for customers. Shuliy Machinery has manufactured plastic film recycling machines for over ten years and exported them to many countries such as Kenya, Malaysia, Germany, Saudi Arabia, etc.

The equipment of the plastic film recycling line includes a waste plastic crushing machine, plastic washing tank, plastic film dryer machine, automatic feeding machine, PP PE granule extruder, cooling tank, and pellet cutting machine. If you are interested in our plastic recycling machinery, welcome to contact us and we will provide you with the perfect solution.

Introduction of Plastic Granulating Line

The whole waste film recycling line is suitable for crushing, washing, pelletizing, and packaging PE/PP film, woven bags, laminated film, cement bags, waste agricultural film, shrink wrap, drip irrigation belts, and other waste materials with different pollution levels.

Our plastic recycling equipment has been optimized in every step of the process from crushing and washing to pelletizing, which significantly improves production efficiency. The following is an introduction for you.

3D Video of Plastic Film Recycling Line

Features of Plastic Film Recycling Machine

- Our plastic film recycling plant has a wide range of applications and is capable of processing all kinds of waste plastic film materials.

- Each machine in the production line is optimally designed to ensure high-quality production output.

- Pelletizing lines are also designed with the flexibility to be customized according to the type of raw material, production requirements, and the size and layout of the plant, ensuring maximum adaptability to different production needs.

Common Raw Materials of Plastic Washing Pelletizing Line

Our film recycling machine can recycle all kinds of PP LDPE LLDPE PVC BOPP and other kinds of plastics, including but not limited to:

- Waste agricultural film and greenhouse film

- Nonwoven material

- Shrink wrap

- Stretch film

- Rubbish bag

- Bubble wrap

- Laminated film

- Film rolls

- In-house (post-industrial) film waste

- Jumbo bags

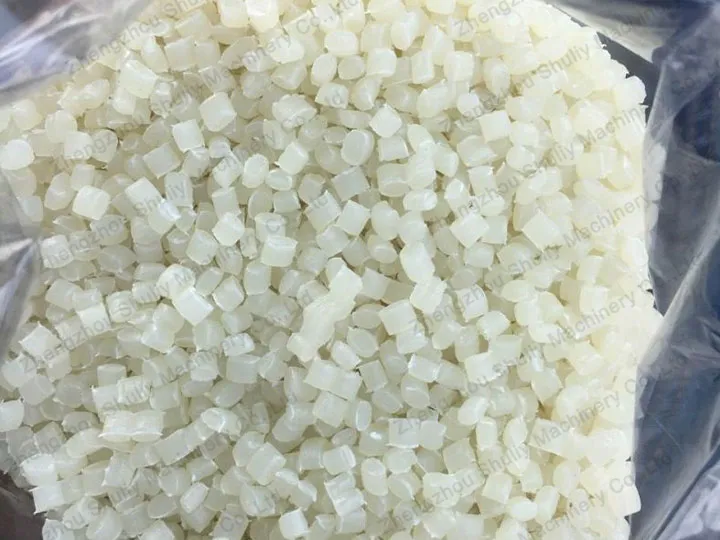

Final Plastic Granules of Plastic Film Recycling Line

Plastic Pelletizing Process

The raw materials are crushed by a plastic film shredder and then enter a plastic washing tank for thorough washing. Wet plastic film fragments are dried by a vertical dewatering machine and then heated to melt into a paste.

The granulator for plastic recycling will produce hot strips that are cooled by a cooling tank and enter the pellet-cutting machine. At this point, they are evenly cut into small granules. Finally, these recycled particles will be stored in a plastic pellet storage silo.

The equipment of the plastic film recycling line can be flexibly configured according to the raw materials and needs of customers.

Plastic Film Recycling Line Video

Equipment Introduction of Plastic Film Recycling Line

Plastic Crusher

The plastic crusher is mainly used for crushing and cleaning waste plastic products such as used agricultural films and woven bags. The machine uses blades made of 60Si2Mn material, and the cutting knife is specially treated to crush the material into small pieces in a short time.

After the raw material enters the plastic film shredder, it undergoes high-speed rotation to crush large pieces of plastic. And the crushed plastic is filtered through the screen for output. Sieve mesh aperture size between 40-50mm.

Rinsing Tank

The plastic rinsing tank is used to clean the impurities such as mud and sand attached to the surface of waste recycled plastic pieces. It is made of stainless steel or iron plates and is available in a variety of models.

There are many stirring wheels in the tank that force the plastic chips to move forward and transfer the material in the pool from one end to the other end of the pool. The drain port is optimized and designed to be 200mm large diameter for fast drainage and improved productivity.

Vertical Dewatering Machine

The vertical dewatering machine is mainly used in the conveying process after crushing and rinsing to replace manual material retrieval and increase the function of cleaning and automatic high-speed dewatering, thus achieving the remarkable purpose of saving labor and electricity consumption, while matching with automatic conveying device to form an automatic assembly line production.

Automatic Feeding Machine

The forced feeder is an essential auxiliary equipment for film, woven bags, and other recycled plastic pelletizing machines. The material is bitten by the screw of the feeding device and continuously and evenly supplied to the host machine to swallow in.

The speed control system can adjust the amount of feeding control, to replace the manual feeding operation, to avoid uneven manual feeding, prone to safety accidents, to achieve the purpose of saving, safety, and efficiency.

Plastic Granulator Machine

The plastic film pelletizing machine is the most important equipment in the plastic film recycling line, which melts the plastic at high temperatures and then extrudes it into long strips to achieve granulation.

The dried plastic chips enter the plastic film pelletizing machine, melt by the heating system, flow out from the main machine outlet, and then enter the auxiliary machine. Under the extrusion of the auxiliary machine, it is extruded from the die head.

Cooling Tank

The plastic cooling tank is mainly used to cool the soft strip plastic materials extruded from the plastic recycling pellet machine and harden them. It is made of stainless steel, which ensures no rust and corrosion when in contact with water for a long time.

Pellet Cutting Machine

The plastic granule cutting machine is to cut plastic strips into plastic granules. The size of the pellets cut out is even. The plastic pellet cutter is easy to operate and has superior performance. The rotary knife adopts a hard alloy hobbing knife with high wear resistance, which is suitable for cold-drawing granulation of various plastics.

Storage Bin

The stainless steel plastic granule storage silo is suitable for storing plastic pellets. It can automatically blow the produced plastic granules into the bin through an induced draft fan, which is convenient for packing and saves labor.

Detailed Information on Plastic Film Recycling Plant

| Capacity | 100-500kg/h |

| Applicable plastic materials | PP LDPE LLDPE PVC BOPP CPP OPP POF film |

| Raw materials | PP raffia bags, waste agricultural film, greenhouse film, nonwoven material, shrink wrap, stretch film, bubble wrap, laminated film, film rolls, in-house (post-industrial) film waste, jumbo bags, plastic strapping, drip irrigation belt |

| Finished products | Recycled plastic granules |

| Customizability | Can be customized |

| Optional equipment | Horizontal dryer, mobile silo, smoke removal device, strip blowing machine, strip shaking machine |

| Installation method | Online guidance or on-site assistance |

| Warranty | 1 year |

Successful Cases of Plastic Washing Pelletizing Line

Plastic Film Recycling Line Shipped to Oman

Shuliy Machinery has made a deal with an Omani customer for a plastic film recycling line and the machine has been successfully delivered to Oman. We look forward to its successful operation in Oman.

1000kg/h Plastic Granulating Line Successfully Installed in Saudi Arabia

The Saudi Arabian customer purchased a complete plastic washing pelletizing line from Shuliy Machinery, which is mainly used for recycling plastic film, woven bags, etc. The whole plastic film recycling line was successfully installed and operated with the on-site assistance of our technical manager.