Our complete plastic bottle recycling line is the ideal solution to start your plastic bottle recycling business. This plastic bottle recycling machine is used to convert dirty PET bottle bales into clean PET flakes.

We offer standard washing capacities from 500kg/h up to 6000kg/h, and can also customize a PET bottle washing line with smaller or larger capacities to suit your needs.

For queries about PET bottle recycling machines, whether it’s about a quote or operational details, feel free to leave your questions in the message box on the website. Our professional sales manager will contact you in the shortest time to provide you with detailed product information and a quotation program.

Introduction of PET Bottle Recycling Line

The plastic bottle recycling machine is mainly used to recycle waste PET bottles, such as mineral water bottles, beverage bottles, etc. Through crushing and cleaning, the final product is clean and transparent flakes. These bottle flakes can be further processed into fibers, PET strapping, PET clear film, or granules.

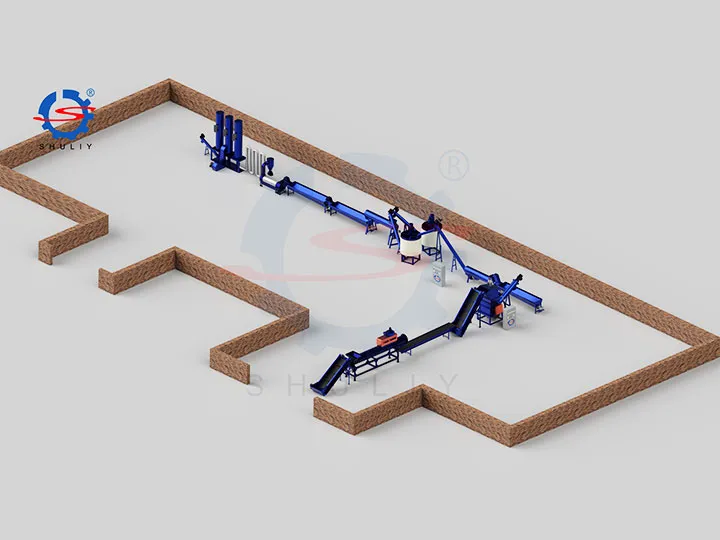

The equipment of the whole plastic bottle recycling line includes a PET bottle label remover machine, PET plastic crusher, hot water washing tank, frictional washing machine, horizontal dryer, and so on. The whole PET bottle washing plant is highly automated, and each step of the equipment is carefully designed and strictly controlled to maximize the quality of the final PET bottle flakes.

Working Video of Plastic Bottle Recycling Machine

Raw Material and Final Products of PET Bottle Washing Line

So what materials can our PET bottle recycling machine recycle? Next, we will continue to introduce them to you.

PET plastic has a wide range of applications in the packaging field. It is widely used not only for packaging beverages, mineral water, tea drinks, etc. But also for food, chemical, pharmaceutical packaging, and many other fields.

After a series of processing steps such as de-labeling, crushing, and washing, waste PET bottles are finally recycled into clean, uniform, and unadulterated high-quality PET bottle flakes. Our plastic bottle recycling line is capable of producing high-quality PET bottle flakes in pure white and light blue colors to meet the market demand for high-end recycled materials.

These high-quality recycled PET bottle flakes can be sold to plastic product manufacturers, textile companies, and packaging companies for use in making new plastic bottles, food containers, fiber products, and more.

Working Process of Plastic Bottle Recycling Line

Recycling PET requires a series of sorting and cleaning processes to turn our waste into recycled material that can be used to make new PET plastic products.

Work process: Remove bottle label-crush-clean/separate bottle caps-hot washing-friction washing-drying-storage. We can optimize the recycling process according to the throughput as well as the degree of soiling of the material, e.g. by adding one or two rinsing steps after friction washing to ensure the cleanliness and quality of the recycled material.

By optimizing the treatment process in each step, our plastic bottle recycling line not only improves the recycling efficiency but also ensures the high quality of the finished products, providing customers with the best quality recycled materials.

3D Video of PET Bottle Recycling Plant

The video below details the entire recycling process of our 1000kg/h PET bottle washing line. In addition to this, we also offer other solutions with different throughputs, such as 500kg/h and 3000kg/h, to meet the diverse needs of our customers.

Main PET Bottle Recycling Machine

PET Bottle Label Remover Machine:

The PET bottle label remover machine is a device that peels off the label paper on various types of PET bottles. The separation efficiency of this machine can reach 98%-99% for round bottles and 90%-93% for flat bottles, which can reduce the PVC content in PET bottle flakes to ≤100-300mg/kg.

PET plastic crushers can efficiently crush waste plastic bottles and break them into uniform-size PET flakes, which is convenient for subsequent washing.

The blades of the machine are made of 9CrSi material and the screen size is 16-18mm, which can be adjusted according to the specific needs of customers.

The sink float plastic separation utilizes density to separate caps or residual labels from PET bottle flakes, controlling polyolefin content to ≤200-300 (mg/kg).

By using hot water and detergent, this PET bottle flakes hot washing machine effectively removes residual adhesive, impurities, and more. The water temperature is 85-90 degrees and the washing time is 30-45 minutes.

The barrel wall of the PET friction washing machine is a rubbing plate design with strong friction. During its work, the internal screw rotates at high speed to make the stains attached to the bottle pieces fall off. The machine is typically placed at a 45-degree angle to facilitate better drainage.

The plastic dryer machine is used to remove water from PET bottle flakes with dryness of up to 95-98%. The back can be connected to the drying pipe, which is made of 304 stainless steel and can control the moisture at 0.5%-1%.

1000kg/h Plastic Bottle Recycling Plant Specifications

Taking a 1000kg/h plastic bottle recycling plant as an example, the specific parameters of each equipment are as follows:

| Item | Specifications | Qty |

| Plastic bottle label remover | Voltage: 380V, 50HZ, 3-phase electric Power: 15+3+1.5kw Barrel length: 4.3m, diameter: 0.63m Round bottle off-label rate 98% PVC content/(mg/kg) ≤ 100-300 (mg/kg) | 1 |

| PET bottle shredder | Voltage: 380V, 50HZ, 3-phase electric Power: 37+1.5KW+1.5kw Tool: 9Crsi Production: 1000KG/H Screen size: 18mm Knife plate thickness: 40mm | 1 |

| Sink float separation tank | Voltage: 380V, 50HZ, 3-phase electric Power: 3KW Outer wall thickness: 4mm Blade thickness: 6mm Equipment size: 5000 * 1000 * 1000mm Control polyolefin content ≤ 200-300 (mg/kg) | 3 |

| PET flakes hot washing machine | Voltage: 380V, 50HZ, 3-phase electric Motor 4kw Electromagnetic heating power: 80KW Height: 2000mm, diameter: 1300mm Outer wall thickness: 4mm Bottom thickness: 8mm | 2 |

| Plastic friction washer | Voltage: 380V, 50HZ, 3-phase electric Power: 7.5KW Barrel length: 3000mm, diameter: 400mm Blade thickness: 6mm | 2 |

| PET flakes dryer machine | Voltage: 380V, 50HZ, 3-phase electric Power: 15KW Remove moisture and achieve a drying degree of around 95-98% | 1 |

| Drying pipes | Voltage: 380V, 50HZ, 3-phase Diameter 159mm, length 15m Heating power 30kw Motor 7.5+3kw The contact material part is made of 304 stainless steel Moisture content (%) ≤ 0.5-1%“ | 1 |

| Winnowing machine | Voltage: 380V, 50HZ, 3-phase Diameter 0.8m, height 4.5m Motor 2.2kw * 3 Auxiliary fan: 0.75 * 3 Elevator motor 3kw Used to remove residual small trademarks and dust Outer wall thickness: 3mm Blade thickness: 6mm Impurity content/(mg/kg) ≤ 300-500 Powder content/(mg/kg) ≤ 2000-3000 | 1 |

Drying ducts and winnowing machines are used in production scenarios with high volumes or high demands on the final product. We can also equip PET bottle bale breaker and trommel according to the customer’s requirement, the whole recycling process is very complete, which can guarantee the quality of final PET bottle flakes very well.

FAQs of PET Bottle Washing Line

What is The Output of This Production Line?

The output of Shuliy’s PET bottle washing line ranges from 500-6000kg/h.

Can the PET Bottle Washing Plant Be Customized?

Yes, Shuliy can customize production lines based on customer raw material conditions and customer needs.

How Many Times Do Plastic Flakes Need To Be Washed?

If your raw materials are dirty, you can choose to clean them multiple times, such as choosing two plastic washing tanks or two frictional washing machines.

Successful Project of Plastic Bottle Recycling Line

Plastic Bottle Recycling Line Shipped to Mozambique

Our company successfully exported a 1000kg/h PET flakes washing line to Mozambique. Our customer in Mozambique, who has been in the plastic bottle recycling business for many years, was ready to buy a new PET flakes washing line and the customer contacted us through our website. The customer is very satisfied with our service and the machine. If you have the same need, please feel free to contact us.

PET Bottle Washing Line Successfully Running in Nigeria

A Nigerian customer who purchased a plastic bottle recycling line from Shuliy Machinery has recently shared a feedback video with us. The plastic bottle recycling line is now operational and in production!

Plastic Bottle Recycling Line Exported To South Sudan

We are pleased to announce the successful export of a plastic bottle recycling line to South Sudan. The recycling line, with a capacity of about 500 kg/h, helps the South Sudanese customer to process waste PET bottles into recycled PET bottle flakes. Here is a picture taken when the machine was tried out.

How To Buy And Install PET Bottle Recycling Machine?

The process of purchasing and installing the plastic bottle recycling line is simple and efficient. First of all, you can contact our sales team through our website or customer service hotline to provide your specific needs and recycling volume requirements.

We will recommend the most suitable recycling equipment model for you and provide you with a detailed quotation and technical parameters. Once the order is confirmed, our team will arrange the production and logistics transportation of the equipment.

Upon arrival of the equipment, our professional technicians can go to your plant for installation and commissioning to ensure the normal operation of the equipment and training of your operators. Our after-sales service team is always ready to provide you with technical support and maintenance services to ensure the smooth operation of your plastic bottle recycling line.