Cement bags, commonly made of plastic, are often overlooked as a potential recyclable material. However, many are unaware that a film granulator can be used to recycle discarded cement bags, transforming them into useful plastic pellets. This not only aids in waste reduction but also contributes to the sustainable utilization of resources.

This article will give you an introduction to how to use the plastic film recycling machine to recycle cement bags.

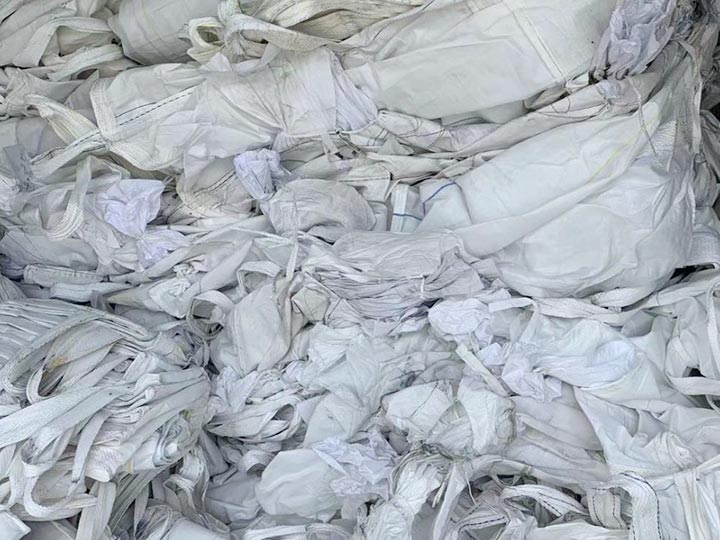

Step 1: Collecting Discarded Cement Bags

The first step is to collect discarded cement bags. These bags can typically be found at construction sites, landfills, or recycling centers. Ensure that the bags are clean and free from mud or other debris to facilitate further processing.

Step 2: Crushing and Washing

The collected cement bags are first crushed into small pieces using a plastic bag crusher machine, which helps to increase the efficiency of the film granulator and ensures the uniformity of the granules. The bags are then washed to remove adhering dirt and residue and to ensure purity of the material.

Step 3: Using a Film Granulator

Now it’s time to utilize a plastic film recycling machine. The film granulator heats and melts cement bags, converting them into granular plastic. Precise control of temperature and pressure in the pellet making machine is crucial to ensure the quality of the final plastic pellets.

Step 4: Packaging and Reusing Plastic Pellets

Once the pellets are formed, they can be packaged and stored for future use or sale. Finally, these recycled plastic pellets can be reused. They can be used to make new plastic products such as pipes, rubbish bags, furniture, etc. In this way, discarded cement bags are turned into a useful resource, and the environmental impact of plastic waste is reduced.

Recycling cement bags using the film granulator is a viable environmental practice. It helps reduce the amount of waste and extends the life of the plastic material. By following the above steps, we can better recycle and reuse the waste cement bags and get useful recycled plastic pellets.