Plastic extruder pelletizer is used to process plastic waste or raw materials into pellets for the production of various plastic products. However, the output of plastic recycling granulators can be influenced by numerous factors. Understanding these factors is essential for optimizing the production process. This article will delve into the factors that can affect the output of plastic extruder pelletizer and provide corresponding solutions.

Quality and Type of Raw Materials

- Material Quality: The quality of plastic raw materials directly impacts the output. High-quality materials are usually more easily processed into pellets, while lower-quality materials may result in reduced output.

- Solution: Choose high-quality plastic raw materials that meet manufacturing requirements.

Temperature Control of Plastic Extruder Pelletizer

- Heating System: Temperature control is critical in plastic pelletization. Incorrect temperature settings can lead to inadequate melting of materials or excessive heat generation, affecting output.

- Solution: Regularly inspect and calibrate the heating system of the plastic recycling granulator to ensure temperatures are within the appropriate range.

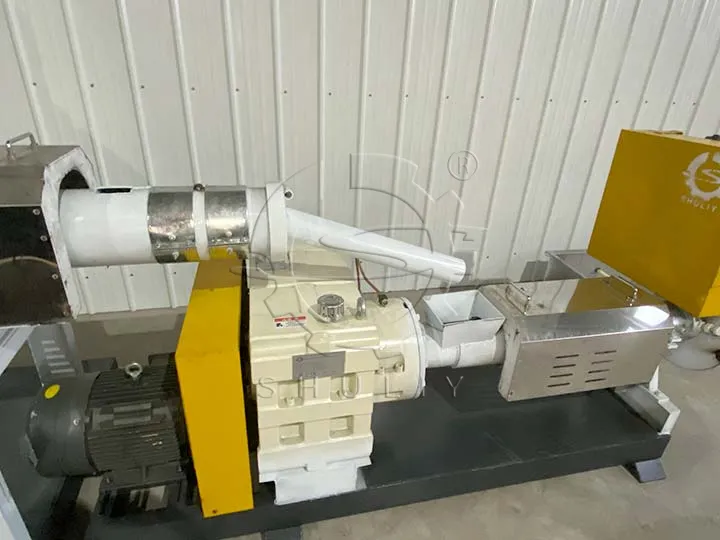

Screw Design and Condition

- Screw Design: The design and dimensions of the screw can affect output. Inappropriate screw designs may not efficiently extrude materials.

- Screw Wear: Wear and tear on the screw can decrease extrusion efficiency.

- Solution: Select suitable screw designs, and routinely inspect the screw’s condition, replacing worn screws as needed.

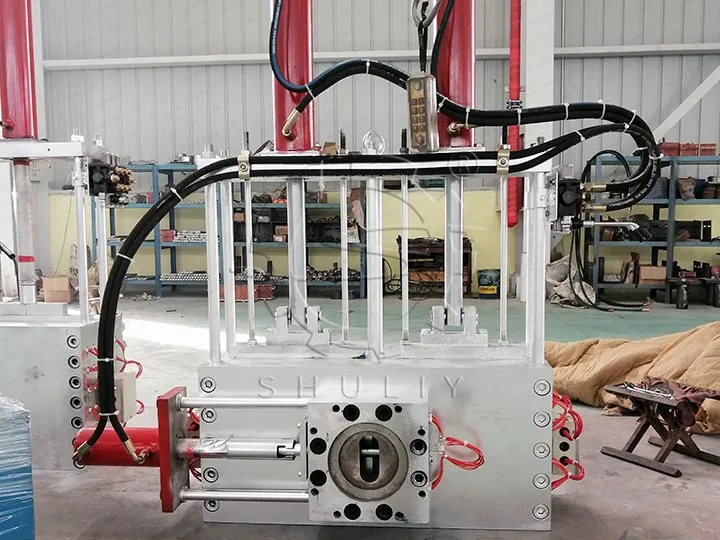

Die Head Design and Cleanliness

- Die Head Design: The design and dimensions of the die head directly impact pellet shape and size, thus affecting output.

- Die Head Cleanliness: Accumulation within the die head can lead to extrusion issues, impacting output.

- Solution: Choose die heads that suit production needs, and regularly clean and maintain die heads as necessary.

Operator Skills

- Operator Skills: The skill level of operators is crucial for operating plastic extruder pelletizer effectively. Skilled operators can better control the machine, improving output.

- Training and Education: Continuously improving operator skills can enhance production efficiency.

- Solution: Provide operator training and education to ensure they understand how to operate and maintain the equipment correctly.

Machine Condition and Maintenance

- Machine Condition: The overall condition and maintenance of the plastic recycling granulator can impact output. Equipment wear or malfunctions can lead to production interruptions.

- Solution: Regularly inspect and maintain the plastic extruder pelletizer to ensure it’s in optimal condition.

In summary. The output of plastic extruder pelletizers is influenced by various factors, ranging from the quality of raw materials to temperature control, screw and die head design, operator skills, and equipment maintenance. Understanding and addressing these factors can help maximize the output of plastic pellet makers, improve production efficiency, and ensure the production of high-quality plastic pellet products. In practical production, considering these factors holistically contributes to sustainable manufacturing processes.