Plastic foam crusher is widely used in recycling industries such as waste foam leftovers, packaging foam, disposable lunch boxes, insulation boards, extrusion boards, foam boxes, insulation boards, heating materials, etc.

This machine can crush waste foam into small pieces, and then foam pieces are blown into a plastic foam extruder for recycling and granulation. The machine is easy to operate and produces almost no dust. It is an ideal choice for foam crushing and recycling.

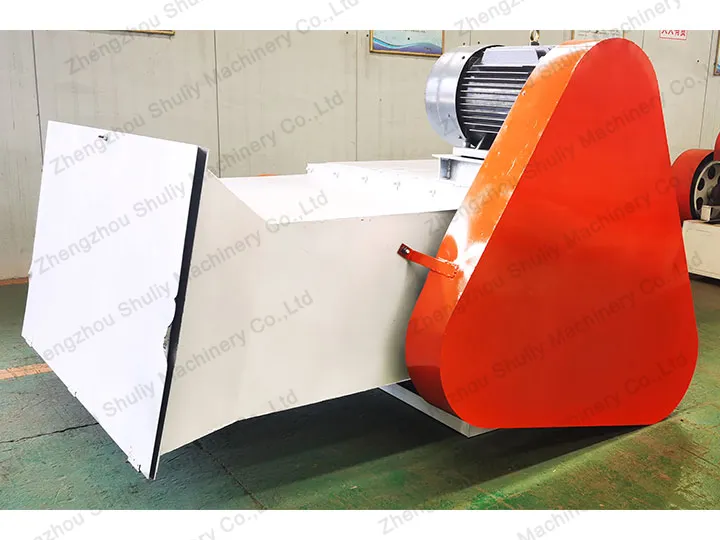

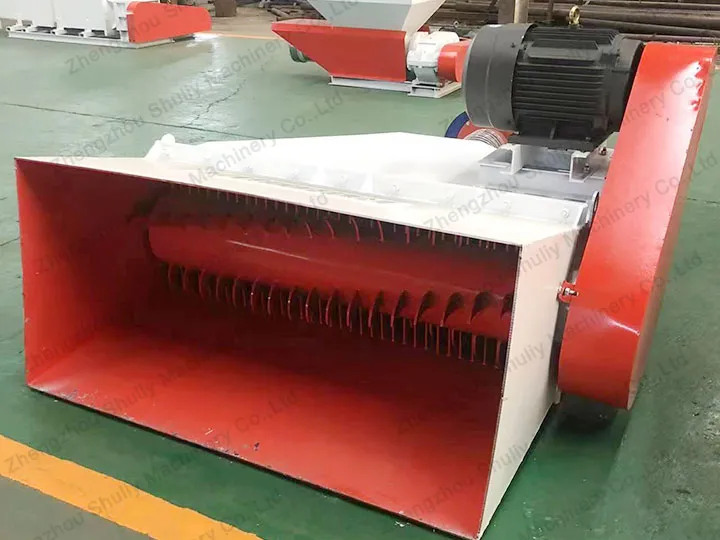

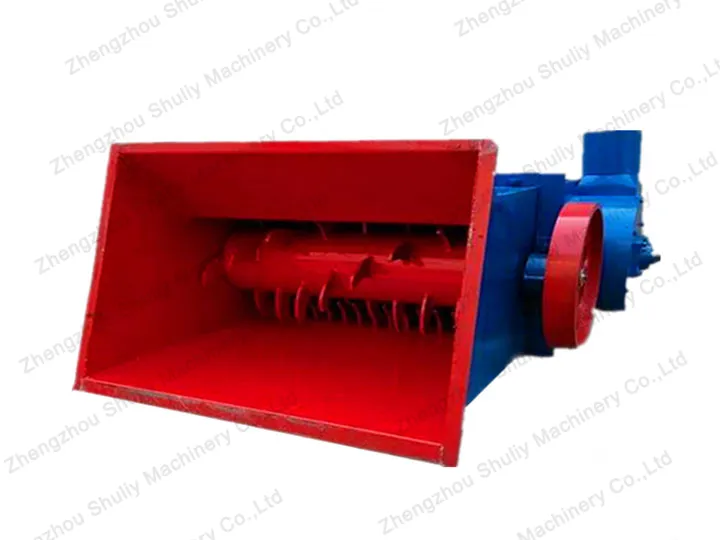

Structure of Horizontal Foam Crusher

- Inlet: The EPS foam inlet where the material is fed into the shredder. The feed opening is flush with the ground so that the material can be pushed directly into the crusher, saving labor.

- Cutting room: The area for crushing materials, containing the rotating blade or cutter for decomposing foam.

- Motor and drive system: to power the plastic foam crusher.

- Emission system: output mechanism. Transports shredded foam to a collection point, such as a bag, container, or other equipment for further processing.

Raw Materials of Plastic Foam Crusher

The plastic foam crusher is suitable for crushing all foam plastic products before granulation. Including disposable lunch boxes, insulation boards, foam boxes, fruit net covers, and protective layers of household appliances.

Parameters of Horizontal Foam Crusher

| Type | SL-800 | SL-1000 | SL-1200 | SL-1500 |

| Overall size (mm) | 1250*1290*660 | 1250*1530*660 | 1300*1730*700 | 1600*2200*800 |

| Feed port size (mm) | 800*600 | 1000*600 | 1200*600 | 1500*800 |

| Capacity (KG/H) | 250-300 | 300-350 | 400-450 | 450-500 |

| Power (KW) | 5.5 | 5.5 | 7.5 | 11 |

Plastic Foam Crusher in plant