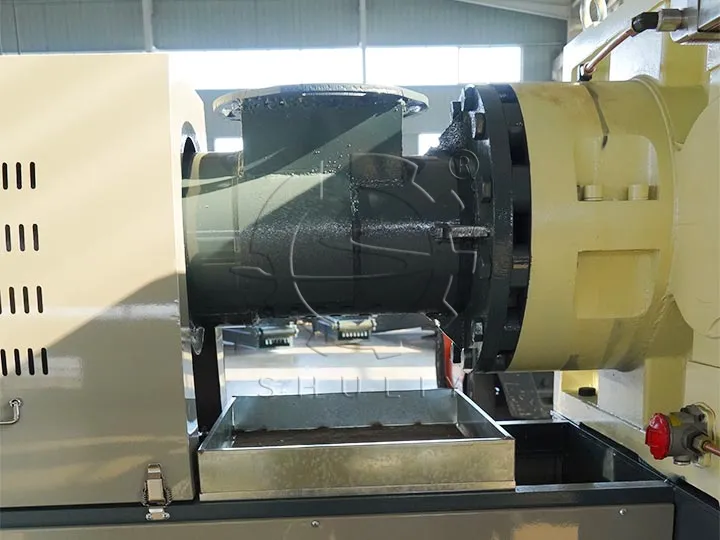

Sometimes, when using pelletizer equipment, you may encounter issues where it’s not discharging properly or the discharge speed has significantly decreased. This can lead to production delays and reduced efficiency. Let’s explore why this happens and how to address the problem.

Inadequate Plastic Melt Temperature

Problem Cause: Insufficient plastic melt temperature can be a significant reason for slow discharge. If the plastic melt temperature isn’t high enough, it can’t effectively extrude through the die.

Solution: Ensure that the plastic melt reaches the appropriate temperature by adjusting the heating zone temperatures according to the material type and specifications. Additionally, check if the heating system is working correctly to ensure even heating.

Improper Die Design

Problem Cause: The design and dimensions of the die may not be suitable for your current production needs, leading to a slow discharge.

Solution: Inspect whether the die’s design and dimensions of pelletizer equipment are appropriate for your production requirements. Replace the die with a suitable one if necessary to improve discharge speed.

Inappropriate Screw Speed

Problem Cause: The screw’s rotational speed may not be suitable for the current production material, resulting in inadequate extrusion of the plastic melt.

Solution: Adjust the screw’s rotational speed to accommodate different materials and production requirements. Ensure that the screw can provide sufficient extrusion force.

Feeding Issues of Pelletizer Equipment

Problem Cause: There might be blockages or uneven feeding in the feeding system, affecting the discharge speed.

Solution: Regularly inspect the feeding system to ensure that the feeding inlet is clear. Clean or replace components of the feeding system as needed to ensure uniform feeding.

Improper Pressure Control

Problem Cause: The pressure control system of the recycling granulator machine may not be correctly adjusted, leading to unstable discharge speeds.

Solution: Check the pressure control system’s set values and ensure they match your production requirements. Make adjustments as needed to ensure a stable discharge speed.

Material Quality Issues

Problem Cause: Low-quality or unsuitable materials for the pelletizer equipment can result in slow discharge.

Solution: Use high-quality, specification-compliant plastic raw materials and ensure they are suitable for your recycling granulator machine.

When the pelletizer equipment experiences slow discharge, there’s no need to panic. First, carefully investigate the potential causes of the problem, such as temperature, die, screw, feeding, pressure, and material issues. Depending on the specific cause, take appropriate measures for repair and adjustment. Regular maintenance and upkeep are also key to ensuring the efficient operation of the recycling granulator machine.