The EPS pelletizer is suitable for the production of recycled and mixed-colored granulation of EPS and other plastics, mainly for the granulation of foam boxes, foam boards, foam corner guards, and recycled plastics. The function of the machine is to heat, melt, and extrude the waste EPS foam and then granulate it. These recycled pellets can be used directly in the manufacture of new plastic products, achieving the recycling of resources.

Our EPS pelletizing machine is made of high-quality materials, with a sturdy and durable structure, stable operation, low maintenance cost, and long service life. By using our EPS pelletizer, companies can efficiently process and recycle waste foam and reduce production costs. Welcome to contact us for more product details and technical support.

Features of EPS Foam Granules Machine

- The capacity of the foam granulator ranges from 150-375kg/h.

- Equipped with double speed reducer.

- Screen change without stopping can be realized.

- Can handle a wide range of EPS foam materials.

- Can be customized according to customer requirements.

Applications for EPS Pelletizer

EPS granulator applies to foam products made of various EPS materials. EPS foam is an excellent packaging material, such as household appliances, precision instruments, glassware, ceramic products, arts and crafts, and other products, which can not be separated from EPS foam parts as cushioning packaging. In addition, fast food boxes, insulation boxes, packing peanut polystyrene, etc. are also made of EPS material.

EPS Recycled Pellets

EPS recycled pellets are usually clear pellets. These recycled pellets can be used in the manufacture of new foam products or processes such as injection molding and extrusion, reducing the need for raw materials.

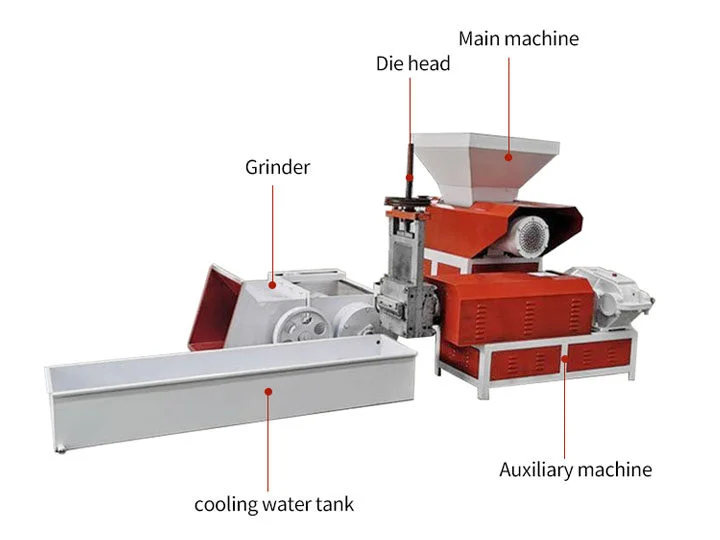

EPS Pelletizer structure

EPS Pelletizer consists of a main machine, auxiliary machine, feeding port, motor, die head, grinder, and heating device.

EPS Foam Recycling Process

Firstly, the waste foam goes into the plastic foam crusher to be broken into small pieces, then into the EPS granulator to be heated and melted, and extruded from the auxiliary machine into the cooling water tank to be cooled, and finally into the plastic pellet cutting machine to be cut into pellets.

Working Video Of EPS Pelletizing Machine

EPS Foam Granulator Parameters

- Raw materials: Foam board, foam box, protective material, packing peanut polystyrene, etc.

- Finished products: EPS recycled pellets.

- Production capacity: 150-375kg/h.

- Equipped with double speed reducer, Electric mold.

- Change the net without stopping the machine.

Why Do We Need to Recycle EPS?

EPS has excellent durable insulation, unique cushioning and shock resistance, aging resistance, and water resistance, so it is widely used in various fields and brings a lot of convenience to our lives. However, most foam products are disposable and are discarded after use, causing environmental pollution. Recycling EPS foam can bring not only economic but also social benefits.