The die head of a plastic pellet machine plays a role in extrusion molding and is a very important component in the extrusion of plastic products. There are three kinds of die heads for plastic recycling granulator machines provided by Shuliy, namely, electric gear die head, hydraulic die head, and messless slagging die head. Customers can choose the appropriate die head according to the output and raw materials.

Application of Plastic Pellet Machine Did Head

Waste plastics need to be plasticized and processed in a plastic pellet machine during the recycling and granulation process. The material is heated and melted in the plastic recycling granulator machine and finally, pressure is created at the die head, then the raw material passes through the mold to form long plastic strips. After cooling and hardening, it is cut into granules and the recycled plastic pellets are obtained.

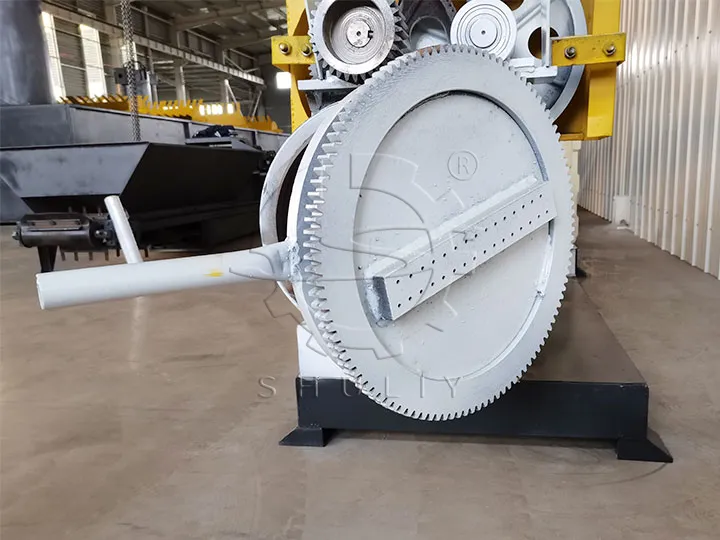

Electric Gear Die Head

The electric gear die head is suitable for plastic pellet machine pull-strip pelletizing, and it has a simple structure, convenient operation, and low failure rate. The whole process of screen changing is very short, and the screen can be changed without stopping or short stopping, which solves the problem of plastic aging and decomposition due to the long time of screen changing in the screw barrel of the extruder, and thus ensures the quality of the products and the production efficiency of the whole production line.

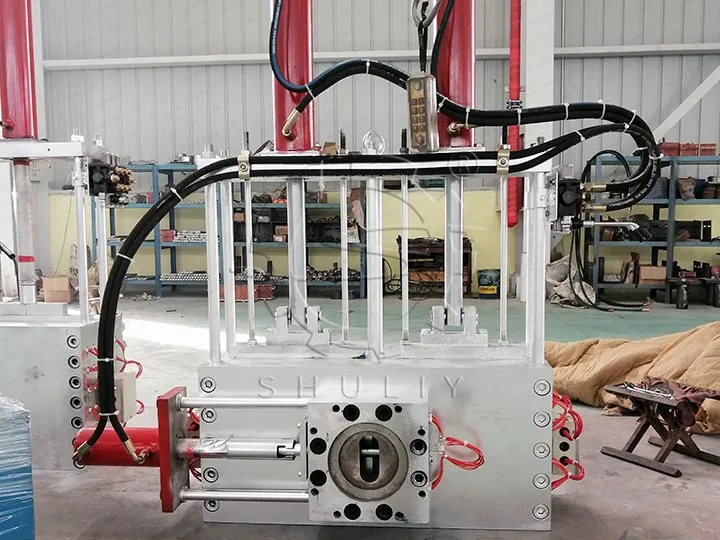

Hydraulic Die Head

The hydraulic die head is the most popular type, it is a kind of screen-changing device designed to achieve easy and fast screen changing, it is a main part of the plastic pellet machine to filter the impurities.

When the impurity attachment increases to affect the plastic passability, it is regarded as a serious blockage of the die head, and it is necessary to replace the screen, at this time, it is only necessary to lift the core plate of the die head, take out the screen with impurities and replace it again, and it is possible to change the screen without stopping the machine.

Meshless Slagging Die Head

The meshless slagging mold head is a plastic filter that does not require the installation of a filter screen, and can also be called an automatic slag filter. The filter of the mold head has anti-clogging unidirectional melt filtration micropores, which allow molten plastic to pass through and block impurities.

In addition, the filtration system is equipped with the synchronous operation of debris removal rotary scraper, when working, the melted plastic through the fine holes, impurities, and dirt left on the side of the filter plate. It has the advantages of automatic debris removal, no need to change the filter screen frequently, enhanced plasticization, low loss of raw material, simple control, and so on.