This plastic recycling pellet machine is a machine used to process plastic waste or raw materials into plastic pellets. Its structure can vary depending on the type and size, but usually contains the following basic components:

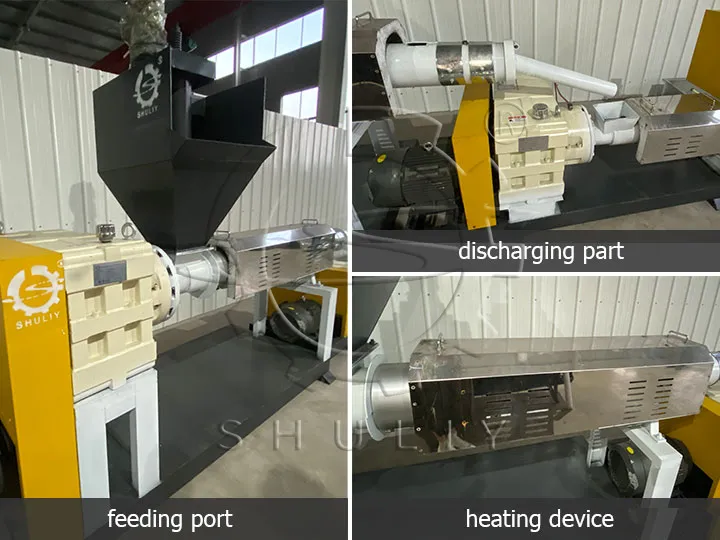

Feeding System of Plastic Recycling Pellet Machine

The feed system of a plastic pelletizing extruder is used to transport the raw material to the processing area. This usually includes equipment such as inlets, automatic feeders, or conveyor belts to ensure that the raw material enters the machine in an even and consistent manner.

Heating System of Plastic Pelletizing Extruder

Plastics need to be heated over a range of temperatures to melt them for subsequent processing. The plastic pelletizing recycling machine has three main heating methods, which are electromagnetic heating, ceramic heating, and ordinary electric heating.

Extrusion System of Plastic Recycling Pellet Machine

The extrusion system is the part that pushes the heated melted plastic into the mold. It includes components such as the screw, screw barrel, and die head. The screw is responsible for pushing the melted plastic forward and applying pressure in the process, causing the plastic to be extruded through the die head into a long strip of plastic.

Transmission System of Plastic Pelletizing Extruder

The transmission system of the plastic pelletizing recycling machine is responsible for driving the screw and providing the necessary torque and speed during the extrusion process. It usually consists of an electric motor, reducer, and bearings.

Shuliy’s plastic recycling pellet machines have been sold to many countries, and our high-quality equipment has been recognized by many customers. We are a professional plastic granulator manufacturer, if you need it, please contact us.