As an important machine in the field of plastic recycling, plastic recycling shredder undertakes the important task of breaking plastic products into small particles. However, a long time of high-intensity operation will lead to wear and tear or damage to some parts, affecting the normal operation of the equipment. In this article, we will analyze the vulnerable parts of the plastic waste crusher machine to help users better understand and maintain the equipment.

Plastic Recycling Shredder Wear Parts

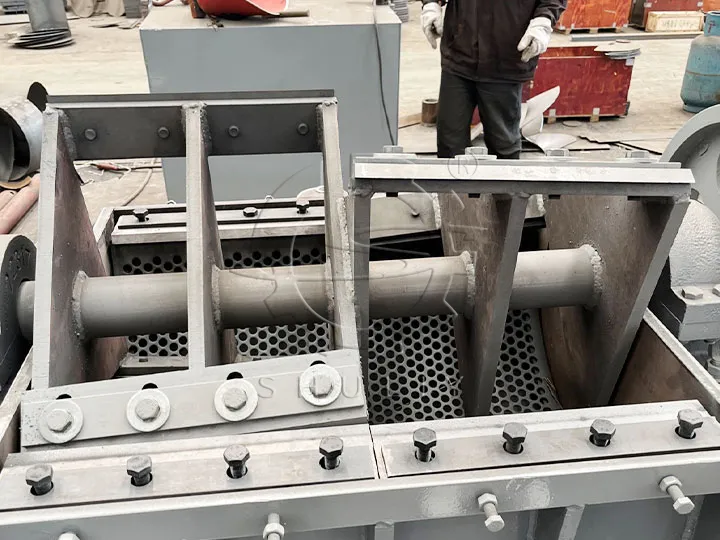

Blades

The blade of a plastic scrap crusher machine is one of its most important parts, responsible for cutting plastic products into small particles. Due to long-time high-speed rotation and high-intensity cutting operation, the blade is easy to wear out, especially the blade part, so it needs to be checked and replaced regularly.

Sieve Net

Plastic recycling shredder screens are used to control the size of plastic debris and prevent oversized or undersized particles from entering downstream equipment. After prolonged use, screens may become damaged or clogged from the impact and friction of plastic debris and need to be cleaned or replaced periodically.

Bear

The rotor and bearings of the plastic waste crusher machine bear important rotational and vibration forces, so the bearings are prone to wear or damage. Regular lubrication checks the condition of the bearings, and timely replacement of badly worn bearings can extend the service life of the equipment.

Electric Motor

The motor of the plastic scrap crusher machine is a key component driving the operation of the equipment. Long-term high-load operation can cause the internal coils and insulation materials of the motor to age or be damaged. Therefore, it is necessary to regularly check the operation status of the motor and carry out maintenance or replacement.

Conclusion

Maintaining the wearing parts in the plastic recycling shredder is the key to ensuring the long-term stable operation of the equipment. Regular inspection, maintenance, and replacement can extend the service life of the equipment, reduce the failure rate, and improve production efficiency.