Horizontal dryers are one of the types of equipment used for washing and drying plastics. It is specifically used for washing and dewatering hard plastic pieces such as PP/PE hard materials and plastic bottle pieces.

Plastic dewatering machines play an important role in Plastic pelletizing lines. Plastic granules need to be completely dried before processing. Excessive humidity tends to deteriorate and agglomerate the granules, affecting the quality of the product.

Our plastic dryer machine has a dewatering rate of 98%, which effectively removes the water contained in the cleaned plastic to the desired level of dryness. Besides, the machine is available in various models and can be customized according to customers’ requirements.

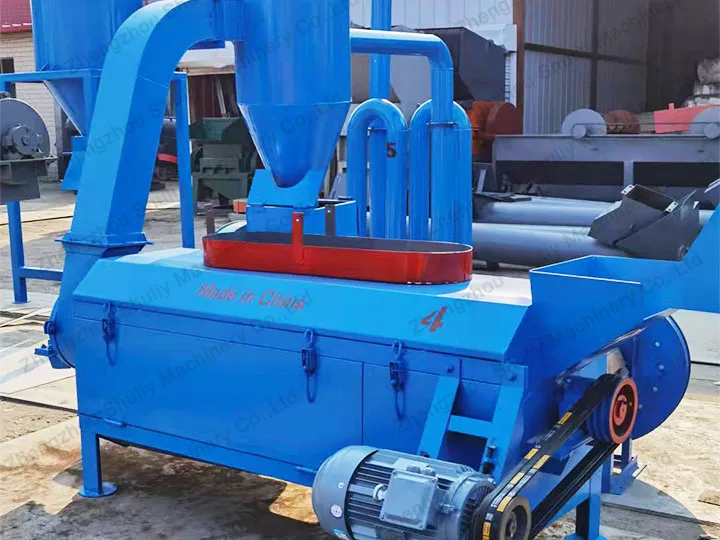

Introduction of Horizontal Dryer For Plastic Recycling

An important part of recycling plastics is dewatering and drying, and the horizontal dryer is an efficient plastic dewatering machine. It is suitable for dewatering and air drying of plastic crushed materials etc. for reuse, with high-speed centrifugal dewatering, automatic discharge, a dewatering rate over 98%, and a high degree of automation.

Application of Plastic Dryer Machine

This machine is suitable for the dewatering of PP/PE hard plastic chips or PET bottle flakes etc. The horizontal dryer is usually used in plastic flake pelletizing lines to dry plastic chips before they enter the waste plastic extruder for pelletizing.

In addition, the plastic chips dryer machine is also suitable for PET bottle flakes washing lines. Moisture is an important criterion in the classification of recycled bottle flakes. Moisture refers to the moisture content, and it is better to contain as little moisture as possible. The plastic dryer machine removes the moisture from the plastic bottle flakes to pack and improve the quality grade of the recycled bottle flakes.

Working Principle of Plastic Dewatering Machine

The horizontal dewatering machine works by using centrifugal force generated by high-speed rotation to remove the water or moisture from the plastic pieces. The plastic enters a rotating drum inside the dewatering machine and the motor rotates the drum at high speed, generating centrifugal force that flings water out of the plastic material through the perforated surface.

Plastic Chips Dryer Machine Features

- Due to the high speed of the plastic dewatering machine, a cyclone is used to discharge the material, which acts as a deceleration.

- Horizontal dryers for plastic recycling have a dewatering rate of 98% and with the addition of the drying duct heaters can reach 99.5%.

- The plastic dewatering machine is versatile and can effectively help dewater broken plastics such as PET bottle flakes, PE flakes, and PP flakes.

- The internal screen of the plastic dewatering machine is made of high-quality stainless steel, and the whole machine is durable.

Horizontal Dewatering Machine Parameters

| Model | SL-550 |

| Capacity | 1000kg/h |

| Outer diameter | 550mm |

| Filter hole diameter | 4mm |

| Length | 1000mm |

Why Do We Suggest You Choose the Shuliy Group?

- Shuliy Group has a wide range of sophisticated and advanced plastic recycling equipment to meet the needs of a wider range of customers.

- We constantly optimize and upgrade our machines to make them more efficient and more in line with actual production needs.

- Shuliy Machinery insists on focusing on the needs of our customers, grasping every detail of communication with them, understanding their needs, responding promptly, and giving reasonable advice.

- We provide our customers with complete production solutions, including factory set-up and installation instructions, free of charge.