Heating devices are necessary for the plastic extrusion process. The heating device is generally outside the barrel and heats the plastic inside the barrel from the outside. There are three main types of heating in the plastic recycling granulator, electromagnetic heating, ceramic heating, and common electric heating. Customers can choose according to budget and need.

Electromagnetic Heating

Electromagnetic heating of plastic recycling granulator is one of the most efficient heating methods.

- Electromagnetic heating has the longest service life because the coil itself does not generate heat and can withstand high temperatures above 500℃. The service life is up to 10 years, and there is basically no maintenance cost in the later period.

- The outer wall of the cylinder is heated by high-frequency electromagnetism, the heat is fully utilized and basically not dissipated. The heat is gathered inside the heating body, and the surface temperature of the electromagnetic coil is slightly higher than the room temperature, which can be safely touched without high-temperature protection, safe and reliable.

- Electromagnetic heating has a very fast hot start, while the thermal efficiency is up to 90% or more. This heating method greatly improves productivity and is energy efficient.

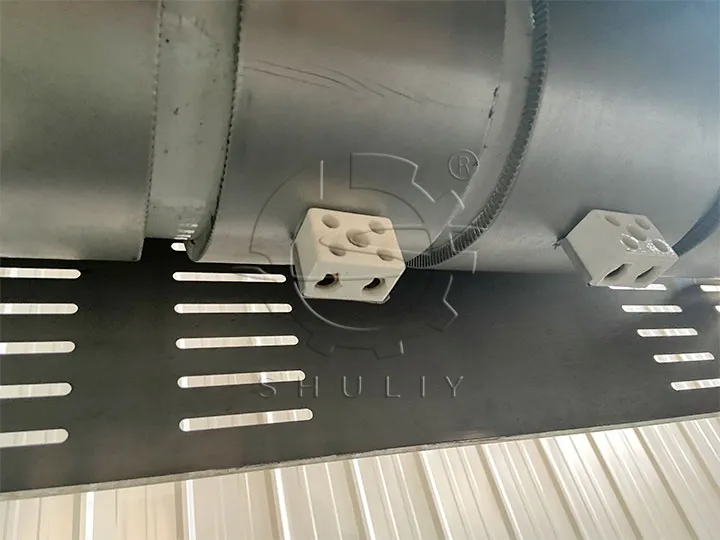

Plastic Recycling Granulator: Ceramic Heating

The outer layer of the ceramic heating ring is made of high-quality stainless steel, and the nickel-chromium alloy heating wire is sandwiched in the middle of the ceramic. The heating ring needs to be close to the sleeve, there can be no gap in the middle. Ceramic heating of plastic recycling granulator heat transfers fast, even heat, stable work, and the power is higher than ordinary 0.5 ~ 1.5 times.

Ordinary Electric Heating

Ordinary resistance heating rings are made of high-quality nickel-chromium alloy heating wire as the heat generator, natural mica as the insulating layer, and galvanized/aluminum plate as the conductive heating layer. If you need a pelletizing machine for plastic recycling, the choice of heating method is important. Customers can choose the right heating method according to the type of plastic, output, and power. If you have any questions, please feel free to contact us.