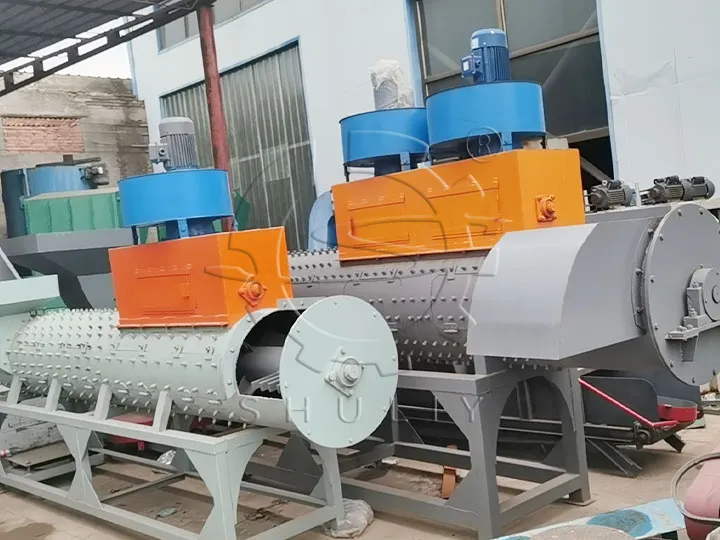

The PET label remover machine is the first process of the PET bottle recycling line. The main purpose is to separate the PET bottle body and label paper, for the ultimate reduction of PVC content in the PET net flakes. This plastic recycling machine greatly improves working efficiency and replaces manual production. In this article, we will introduce the advantages and precautions of the label removing machine.

Advantages of PET Label Remover Machine

- Efficient Label Removal: The label removing machine can quickly and efficiently remove the label paper from PET bottles, ensuring the purity of the final recycled PET bottle flakes.

- Reducing the PVC content of PET net flakes: By separating the PET bottle from the label paper, this plastic recycling machine helps to improve the quality of PET net flakes by reducing the content of impurities such as PVC and meeting the requirements of quality standards.

- Improve work efficiency: The automated operation of plastic bottle label remover greatly improves production efficiency, reduces labor intensity, and replaces the need for manual handling.

- Meet the needs of the PET bottle washing line: This kind of equipment serves as a prelude to the PET bottle washing line, providing clean PET bottles for the subsequent process and ensuring the continuity and stability of production.

Precautions of Plastic Bottle Label Remover

- Safety operation: When operating the PET label remover machine, you must strictly follow the safety operating procedures to ensure the safety of the staff.

- Regular maintenance: Regular maintenance of the machine is essential to keep it running efficiently. The machine’s knives, blades, drive components, etc. require frequent inspection and maintenance.

- Label disposal: Removed labels need to be disposed of properly to ensure environmental health and resource recovery.

- Quality control: The PET label remover machine operation needs to be tightly controlled to ensure that peeled labels are completely separated to meet production standards.