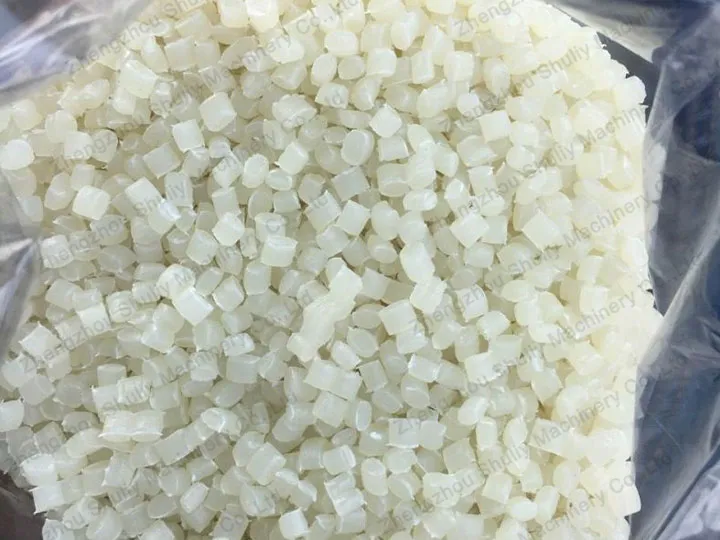

The plastic pellet cutting machine is the final step in the plastic pelletizing line. Our plastic Dana cutter is a state-of-the-art machine designed to cut plastic strips efficiently and accurately. The use of high-quality blades and advanced cutting technology ensures that the plastic strips are cut into uniform and consistent pellets with stable pellet sizes.

The blade speed and cutting length of the pellet cutting machine can be adjusted according to different production needs, adapting to various types and sizes of plastic materials with high flexibility.

Shuliy Machinery has focused on developing and producing plastic recycling and manufacturing equipment for more than twenty years. Our plastic granule cutting machine has been exported to many countries to support their plastic recycling business and bring great economic profit to our customers. If you have the same need, welcome to contact us for more details.

Introduction of Plastic Pellet Cutting Machine

The plastic pellet cutting machine is suitable for plastic granulation lines to cut plastic strips into plastic pellets for recycling and reuse.

A plastic granule cutter is easy to operate and has superior performance. The rotary knife adopts a hard alloy hobbing knife, and the blade rotates at high speed, which can achieve high-efficiency cutting and high wear resistance.

The machine has a high degree of automation and adjustable cutting size, which can meet the needs of different customers. It is suitable for cold-drawn pelletizing of various plastics.

Scope of Use of Plastic Granules Cutting Machine

The plastic pellet cutting machine is suitable for the production of recycled and mixed-color pellets of PP, PE, ABS, PVC, PET, EPE, EPS, and many other plastics. The cooled plastic strips are evenly cut into uniformly sized granules for subsequent processing or reuse.

The plastic pellet cutting machine is suitable for most common waste plastics and is the most versatile, widely used, and popular plastic recycling processing machinery in the waste plastic recycling industry.

Working Principle of Plastic Granule Cutter

The melted plastic is extruded into a continuous strip that melts through the mold die of the plastic pelletizing machine, and the plastic strip is cooled evenly in the cooling tank to make it hard.

Finally, the rubber roller of the plastic pellet cutting machine bites and is synchronously fed into the knife chamber of the plastic granules cutting machine, where the high-speed rotating knife cuts the plastic pulling strips into small particles, thus completing the whole pelletizing process.

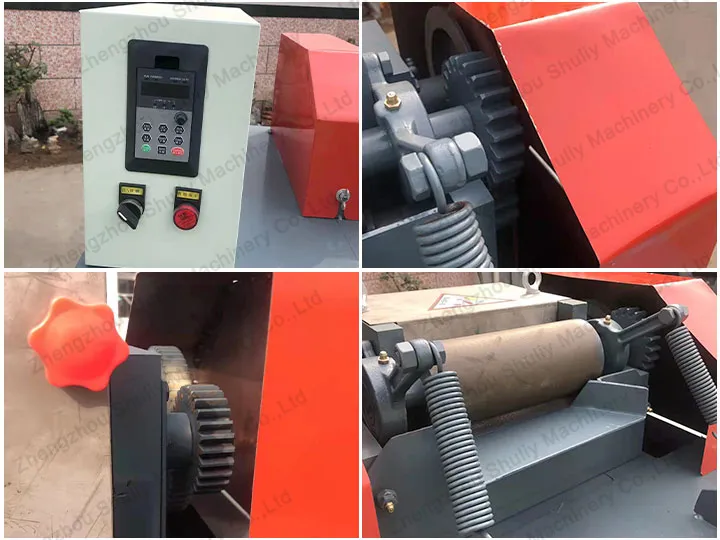

Structural Composition of Plastic Granule Cutter

The plastic granule cutter is mainly composed of an inlet, pressure roller, rubber press rollers, motor, body, and outlet. The whole machine has no gear design, which can effectively reduce the noise of machine operation. The rotating knives are hard alloy hobs with high wear resistance.

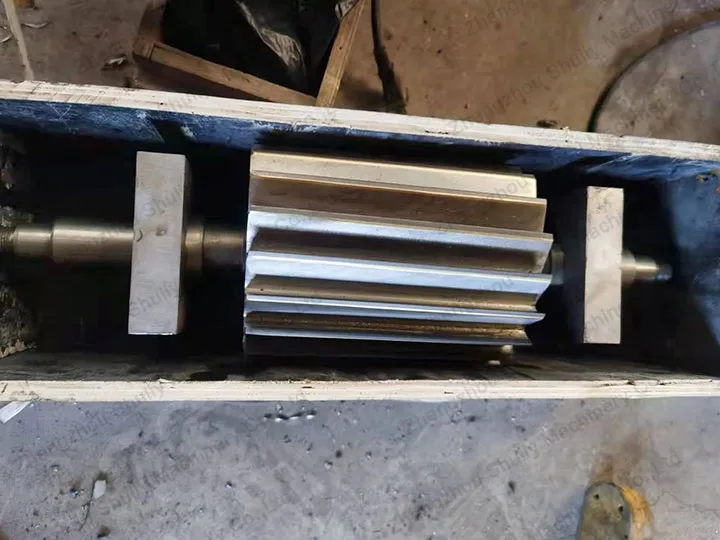

Introduction of Hobbing

The hob knife is a cylindrical diagonal spiral hobbing way, also known as a pelletizer blade. Divided into two kinds of integral steel and welded carbide steel, the manufacturing process is complex and the fixed knife adopts a flat knife strip design.

The hobbing is installed on the rotating spindle of the plastic granules cutting machine and is a mechanical blade used to cut off rubber, plastic, and other recycled granulation materials.

Introduction of Rubber Press Roller

This machine consists of two upper rollers and one lower roller. There are two types of materials for the upper roller: rubber roller and iron roller. The lower roller only has one iron roller. Generally, the lifespan of the rubber roller is short, but it will not damage the formed rubber strip.

Features of Plastic Granule Cutter

- A high degree of automation: The plastic granules cutting machine with an automatic control system can automatically complete the process of feeding, cutting, and discharging. Save labor and improve production efficiency.

- Adjustable cutting size: The cutting size can be adjusted according to customer requirements.

- Easy maintenance: This machine adopts alloy steel blades. The knives are treated with a special process and can cut materials for a long time without wearing them out.

- Wide range of applications: It can be used for granulating waste plastics such as films, woven bags, tubs, barrels, plastic bottles, plastic foam, etc.

Parameter of Plastic Pellet Cutting Machine

| Model | Power(kW) | Width of knives(mm) | Type of knives |

| SL-180 | 3 | 180 | Hob |

| SL-220 | 5.5 | 220 | Hob |

| SL-260 | 5.5 | 260 | Hob |

Recommend Granulator For Plastic Recycling

Granulators for plastic recycling and plastic pellet cutters need to work in tandem. Plastic pellet extruder machines are mainly responsible for transforming raw plastic material into the form of plastic pellets through the process of processing, melting, and extruding. In this process, the plastic is melted and passed through a die to form a continuous strip of plastic.

The plastic pellet cutter is a device that cuts on the continuous plastic strip generated by the plastic pellet extruder machine. Its main function is to cut the continuous plastic strip into plastic pellets of the same or specified length.

Precautions for Using Plastic Granules Cutting Machine

- According to the type of plastic and the required particle size, set the appropriate cutting parameters, such as blade rotation speed, feeding speed, etc.

- Pay attention to the feed rate of raw materials and avoid overfeeding at one time to prevent the cutter from clogging. If clogging occurs, immediately switch off the machine and take the necessary cleaning measures.

- Regularly check the condition of the plastic pellet cutting machine knives to ensure that the blades are sharp and well-fixed.

- Perform regular care and maintenance, including blade replacement, oiling of lubricated parts, etc.