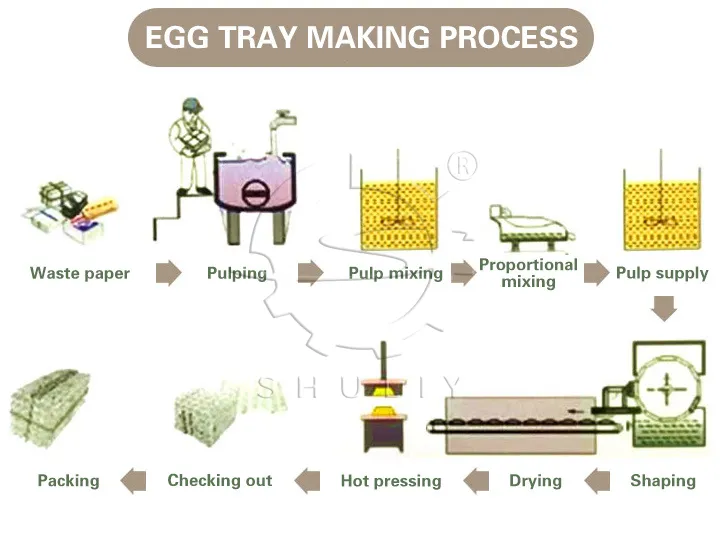

Trong quá trình sản xuất các sản phẩm từ bột giấy định hình, quy trình nghiền bột đóng vai trò quan trọng. Chất lượng của bột giấy ảnh hưởng trực tiếp đến vẻ ngoài, độ bền và tính đồng nhất của sản phẩm cuối cùng. Máy nghiền bột giấy của chúng tôi được thiết kế đặc biệt cho các dây chuyền sản xuất khay giấy như khay trứng, khay trái cây, khay cốc cà phê và các sản phẩm giấy định hình khác, đảm bảo cung cấp bột giấy đồng nhất và đáng tin cậy cho quá trình định hình.

Cách cải thiện chất lượng bột giấy

Chất lượng bột giấy cao có được từ việc lựa chọn nguyên liệu thô phù hợp và thiết bị hiệu quả. Máy nghiền bột giấy của chúng tôi tương thích với nhiều loại vật liệu giấy thải, bao gồm báo cũ, bìa cứng và giấy sách. Chúng đảm bảo trộn đều và phân phối sợi đồng đều, nâng cao độ dày và độ bền của sản phẩm hoàn thiện. Chất lượng bột giấy có thể được cải thiện thêm bằng cách điều chỉnh tỷ lệ nước và giấy cũng như thời gian trộn.

Lợi ích của máy nghiền giấy của chúng tôi

- Cấu trúc đơn giản, dễ bảo trì: Dễ dàng vận hành và kích thước nhỏ gọn, phù hợp cho việc bảo trì hàng ngày.

- Hiệu suất cao, tiêu thụ năng lượng thấp: Hiệu suất động cơ ổn định, nghiền bột hiệu quả và tiết kiệm năng lượng.

- Công suất tùy chỉnh: Có sẵn nhiều tùy chọn công suất khác nhau để phù hợp với các quy mô khác nhau. dây chuyền sản xuất khay trứng.

- Tương thích mạnh mẽ: Dễ dàng kết nối với các máy tạo hình của chúng tôi và tích hợp vào toàn bộ dây chuyền sản xuất.

Quy trình làm việc của máy nghiền giấy

- Xử lý bột nguyên liệuChất thải bìa cứng, báo và các vật liệu khác được cho vào máy nghiền bột. Dưới tác động của dòng nước và ma sát, chúng được phân hủy thành bột sợi và chuyển đến bể chứa bột.

- Trộn bột đầu tiên: Bột được bơm vào bể bột đầu tiên, nơi các tạp chất được lọc ra và nồng độ bột được điều chỉnh.

- Giai đoạn trộn thứ hai: Bột được trộn thêm trong bể bột thứ hai. Các phụ gia như phẩm màu hoặc chất chống thấm có thể được thêm vào khi cần.

- Cung cấp bột để tạo hình: Bột đã chuẩn bị được bơm đến máy tạo hình khay trứng để tạo hình.

Giải pháp sản xuất khay giấy hoàn chỉnh

Chúng tôi không chỉ cung cấp máy nghiền giấy mà còn cung cấp tích hợp hệ thống đầy đủ, bao gồm chuyển giao bột giấy, hệ thống lưu trữ, máy tạo khay trứng, dây chuyền sấy và đơn vị đóng gói. Ngoài ra, chúng tôi còn cung cấp đào tạo vận hành và hỗ trợ kỹ thuật sau bán hàng để giúp khách hàng khởi động và duy trì sản xuất một cách hiệu quả.

Xin vui lòng liên hệ với chúng tôi để biết thông số kỹ thuật chi tiết và giải pháp tùy chỉnh - chúng tôi sẵn sàng cung cấp hỗ trợ chuyên nghiệp và dịch vụ hiệu quả.