The plastic bag crusher machine is specially designed to efficiently shred plastic bags, woven bags, agricultural films, and other plastic film products. The basic principle of this machine is to shred plastic bags into small pieces or pellets by mechanical force. This helps to reduce the size of the plastic for storage and further processing.

We have a wide range of recycling shredders of different sizes and models with different capacities, so you can choose the right size machine for your needs.

Advantages of Shuliy Plastic Film Crusher

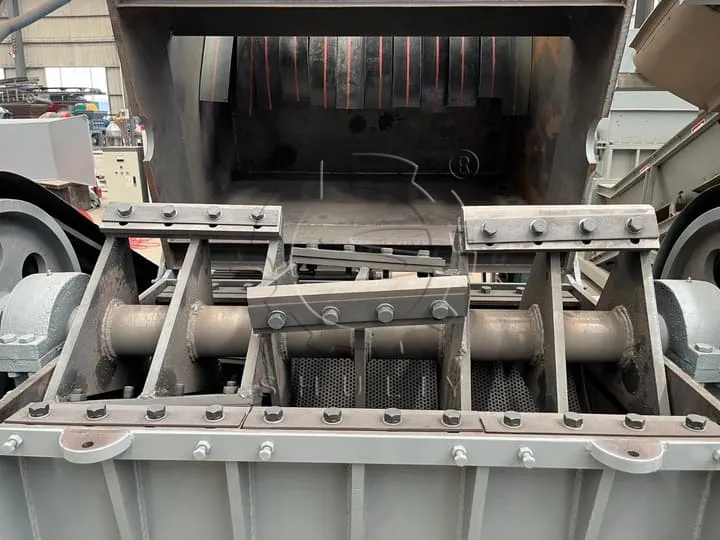

Adjustable Blade Gap

The gap between the fixed and moving knives can be adjusted for different materials of plastic film to ensure the best cutting effect.

Blade Material

The blades of the plastic bag crusher machine are made of 60Si2Mn steel, which has high strength and excellent wear resistance.

Customized Screen Sizes

The screen size range is 40-50mm, which can be customized to meet the production requirements of different particle sizes.

Multiple Power Options

Two power modes, electric motor, and diesel, are available to suit a wide range of working environments and customer preferences.

Anti-clogging Design

Equipped with a U-shaped conveyor and blower, it effectively prevents the clogging problem of lightweight plastic film during processing.

Supports Wet Crushing

Optionally, water can be added for wet crushing to increase the weight of the film for easier handling, while further cleaning the plastic film and improving the quality of the recycled plastic.

Applicable Raw Materials of Recycling Shredder Machine

Our plastic grinder machine is suitable for processing all kinds of plastic products, including but not limited to plastic bags, composting bags, agricultural films, woven bags, stretch films, greenhouse films, nonwoven material, bubble wrap, jumbo bags, frozen food bags, LDPE food packaging, and so on.

These raw materials usually have different shapes and sizes, but the plastic bag crusher machine can effectively convert them into smaller pieces through its powerful shredding capacity, creating conditions for subsequent processing and reuse.

Working Principle of Recycling Crusher Machine

The working principle of plastic film crushers is based on the process of cutting and crushing. Firstly, the plastic products are fed into the shredding chamber, and through the action of the blades and rotating mechanism, the raw materials are quickly cut into small pieces.

Next, the high-speed rotating blades and the materials in the shredding chamber are strongly torn, so that the plastic is gradually turned into smaller pieces. Eventually, these plastics are collided and crushed many times to become plastic fragments that meet the requirements, ready for the subsequent processing steps.

The plastic bag crusher machine screen size is generally 40-50mm in diameter. The role of grinder machine screens is to control the particle size of crushed materials to ensure uniformity and improve crushing efficiency.

Working Video of Plastic Film Crusher

Plastic Film Shredder Machine Parameter

- Capacity: 400-1200kg/h

- Knives: fixed knife, moving knife

- Blade material: 60Si2Mn or 55Crsi

- Screen size: 40-50mm

- Power mode: electric motor, diesel engine

- Model: Various, can be customized

Global Cases of Film Shredder Machine

Plastic Scrap Crusher Machine Sent To Botswana

Botswana wants to set up a plastic waste recycling plant and chose our plastic recycling machines such as a plastic scrap crusher machine, plastic granulation equipment, a plastic washing machine, and so on. We are looking forward to the successful feedback from Botswana customers.

For more details, you can check out: Extruder Plastic Pelletizing Line To Botswana

Plastic Recycling Shredder Installation In Nigeria

Some time ago, our engineers traveled to our client’s plastic waste recycling plant in Nigeria to assist in the installation of a range of equipment, including a film shredder machine, a waste plastic extrusion machine, and PET bottle recycling machines. It is now running successfully.

For more details, you can check out: PE Waste Plastic Pelletizing Line Installed In Nigeria

Benefits of Using Plastic Bag Crusher Machine

- Volume Reduction: Plastic products such as plastic bags, woven bags, etc. usually take up a large volume during waste collection and transport, whereas plastic film crushers can efficiently shred them into small pieces, thus reducing the space required for storage and transport.

- Improve recycling efficiency: Using a plastic bag crusher machine to shred plastic products can speed up subsequent material handling steps, thus improving the efficiency of the entire recycling process.

- Resource Recycling: Shredded plastic fragments can be used as raw materials and reprocessed to make recycled plastic pellets, which can be used to manufacture new plastic products, thus realizing the recycling and reuse of resources.

- Reduced Costs: Plastic bag shredder processing of plastic waste reduces the cost of subsequent disposal because smaller pieces of plastic are easier to store, transport, and process.

Shuliy Plastic Granulation Line For Sale

To meet customers’ needs for the final product, Shuliy Machinery offers a plastic pelletizing line, including a plastic bag crusher machine, a film washing machine, a drying machine for plastic, a plastic granulator, and a plastic pellet cutting machine. This granulation line can process waste plastics into plastic pellets.

Welcome to Consult Shuliy Machinery

Welcome to consult Shuliy Machinery for plastic recycling solutions. As a professional manufacturer of plastic recycling machines, Shuliy Machinery can offer you a reasonable ex-factory price. Our plastic recycling machines are cost-effective and have gained a good reputation in the world market.

If you are looking for equipment to process waste plastics into plastic pellets, our plastic recycling machines are the perfect choice for you. With our commitment to attentive after-sales service, we are confident that our customers will derive profitable value from the machines we offer. If you would like to know more about our equipment, please send us a message.