Recently, a customer from the Congo purchased a complete PET bottle washing plant from Shuliy. The complete washing line includes a plastic bottle label remover, waste bottle shredder, Plastic bottle cap sorting machine, pet bottle flakes hot washing machine, plastic friction washer, and plastic chips dryer machine. This is a vote of confidence in Shuliy Machinery. Please check out the details.

Introduction of PET Bottle Washing Plant

The PET bottle washing plant is mainly used to recycle waste PET bottles, such as mineral water bottles, beverage bottles, etc. Through crushing and cleaning, the final product is clean and transparent flakes. Generally speaking, the production range of this production line is 200-500 kg per hour. The configuration of the PET bottle washing line is relatively flexible and can be customized according to customer requirements.

Why Choose a PET Bottle Washing Plant From the Shuliy Group?

First of all, we are a professional manufacturer of plastic recycling equipment with more than ten years of experience.

Secondly, we have excellent service. After the client contacted us, communication took place to understand the client’s specific requirements and preferences, and Shuliy’s dedicated team provided detailed product information and technical specifications, and addressed any questions the client had. Through this transparent and thorough communication, the client gained confidence in Shuliy’s equipment and services.

Once the order is confirmed, Shuliy starts the production process immediately to ensure on-time delivery and provides installation instructions upon arrival of the machine.

Machine Parameters of PET Bottle Recycling Line

| NO. | Item | Specification |

| 1 | Conveyor | Convey the bottle to the label removing machine Power: 2.2kw Length: 4000mm Width: 600mm |

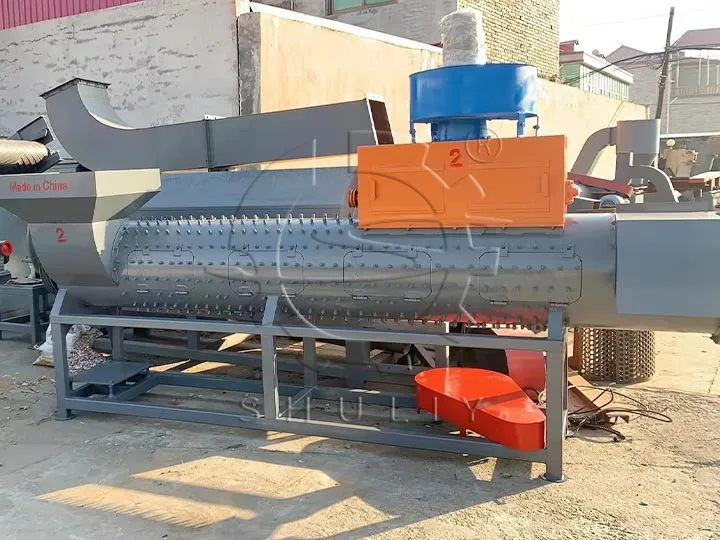

| 2 | PET bottle label remover | Remove the label from the bottle Power: 11kw+2.2kw Size: 4000*1000*1600mm Weight: 2600kg |

| 3 | Plastic bottle shredder | Crush the bottle into small chips Power: 11kw Capacity: 300kg/h Size: 1300*650*800mm |

| 4 | Screw Conveyor | Convey the plastic chips into PET PP washing and separating machine Power: 2.2kw Length: 2500mm |

| 5 | Plastic bottle cap sorting machine | Separate PET chips and PE bottle cap Power: 3kw Size: 5000*1000*1200mm |

| 6 | Rubbing Washing Machine | With water recycling, clean the PET bottle enough, remove cleaning agent and other impurities Power: 5.5kw |

| 7 | PET Chips Dewatering Machine | Dewatering for PET chips Power:7.5kw Size:1300*600*1750mm |

PET Bottle Washing Plant to Congo

Before the machines were packed and shipped, we sent the customer pictures of the machines as well as pictures and videos of the placement sequence of the production line.