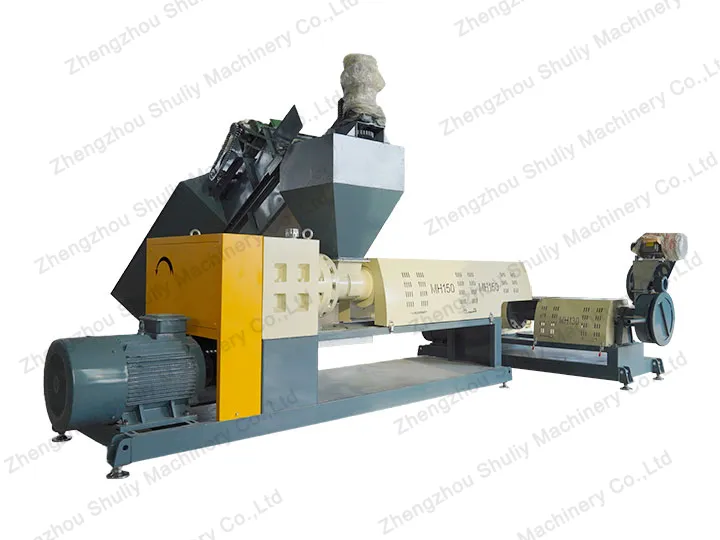

Shuliy rigid plastic granulator machine is suitable for pelletizing all kinds of rigid plastics, such as PP, PE, HDPE, ABS, PS, PVC etc. The plastic recycling machine produces high-quality recycled plastic granules with outputs ranging from 150kg/hour to 500kg/hour. This extruder machine is necessary equipment for the pelletizing line.

If you are looking for a recycling granulator machine and can’t determine the output, you can contact us, we can recommend you the most suitable equipment according to your raw material quantity.

Getting to Know Rigid Plastic Granulator Machine

Through the process of high-temperature melting, extruding, and cutting. This HDPE pelletizing machine transforms waste hard plastic into uniform and stable granules, and it can be widely used in manufacturing plastic pipes, profiles, injection molded products, and many other fields.

Our granulating machine is designed to convert all kinds of rigid plastic materials into high-quality pellets, which can provide high-quality raw materials for the production of recycled plastic products.

The machine can be used alone or with a scrap grinder machine, washing machine, etc. to form a complete pelletizing production line.

Recycling Granulating Machine Advantages

- Pellet quality: The pellets produced are uniform, good in appearance, and meet the industry standard.

- Conversion rate: A high conversion rate, maximizes the use of waste plastics and reduces the waste of resources.

- Heating method: Adopting advanced heating technology to ensure uniform melting of plastic and avoid overheating or underheating.

- Durability: Made of high-quality materials to ensure long-term stable operation and reduce the failure rate.

- Customization: We can provide personalized customization according to customers’ needs and adapt to different production conditions.

- After-sales service: provide comprehensive after-sales support, and quick response to customer needs, to ensure the smooth operation of the equipment.

Pelletizing Recycling Machine Application

The rigid plastic granulator machine provides the best solution for recycling PE, HDPE, PP, PS, ABS, PC, PA, and many other rigid plastic recyclables.

Plastics that can be processed by this machine include but are not limited to plastic drums, pipes, profiles, appliance housings, car parts, plastic containers, plastic flakes, food containers, and rigid plastic parts. You can consult us according to the plastics collected and we will give you the appropriate solution.

The above materials are not all, many materials that can be pelletized are not listed here, you can leave your raw material information, and our business manager will contact you to discuss the program.

Below to better understand the working principle of the granulation machine, we first introduce the main structure of the machine.

Structure of HDPE Pelletizing Machine

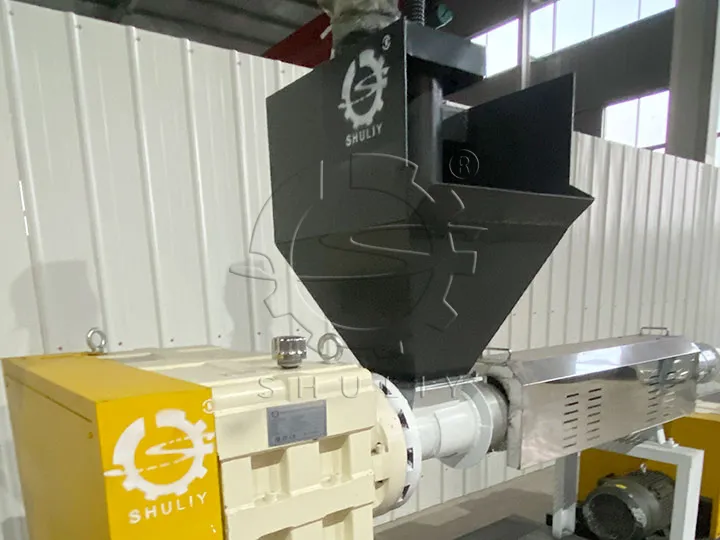

Feeding port: The crushed and cleaned plastics come from here to the pelletizing machine.

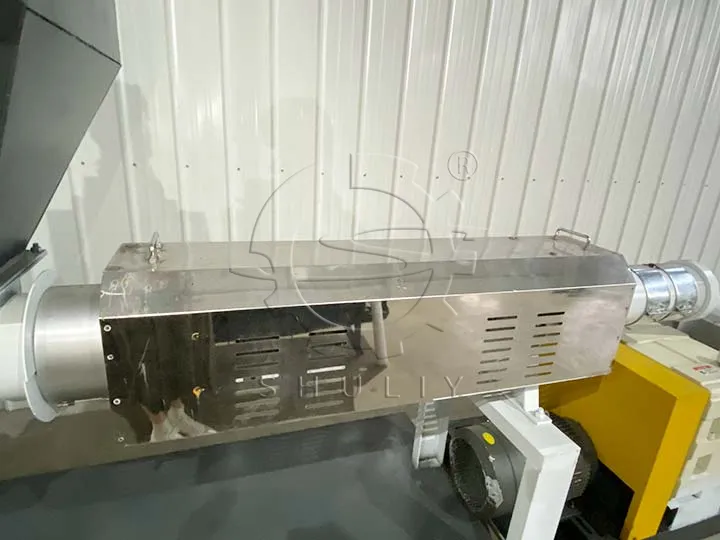

Heating device: The material is melted into a paste using a heating device for subsequent stretching and granulation.

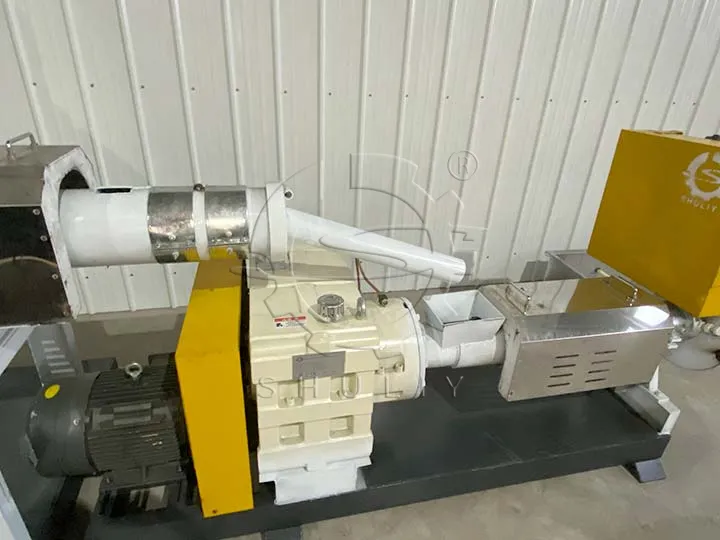

Discharging part: The melted plastic flows out from here into the granulator auxiliary machine.

Screw press: Delivery of material to the die head by rotary extrusion.

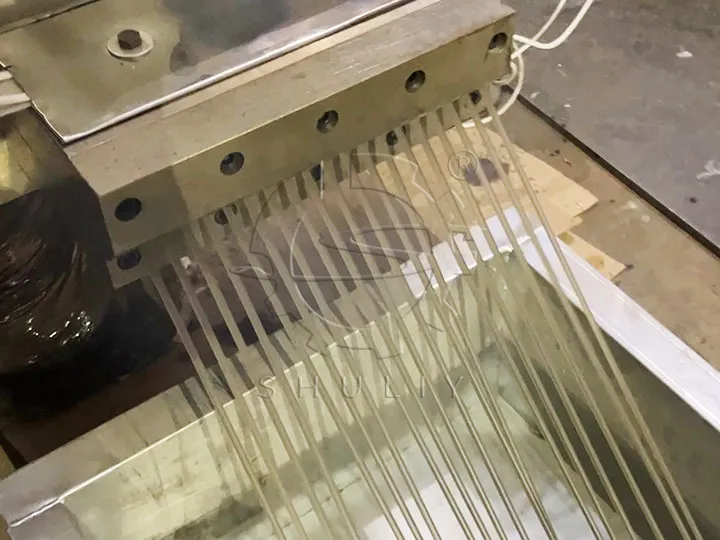

Mold head: The die head is used to extrude the plastic in long strips for subsequent cooling and cutting into plastic pellets.

Working Principle Of Plastic Pellet Making Machine

The principle of the rigid plastic granulator machine is mainly through heating, melting, and extruding plastic materials.

Our extruder machine mostly adopts the strand pelletizing process. Crushed and cleaned plastic sheets are conveyed into the granulating machine, which is melted under the action of the heating device and then extruded through the die head to form continuous long strips.

These long strips are then cooled and fed into the cutting machine, where they are cut into uniform plastic pellets. This process is not only efficient but also ensures pellet quality and is suitable for reprocessing a wide range of plastic materials.

Working Video Of Recycling Granulator Machine

Below is a video of this recycling granulator machine in action, showing how waste plastic is processed into plastic pellets.

Plastic Pellet Extruder Details

| Brand | Shuliy Machinery |

| Capacity | 150-500kg/h |

| Applicable Material | HDPE, PVC, PA, ABS, PP, PS |

| End Product | Plastic granules |

| Pelletizing Method | Strand pelletizing, water ring pelletizing |

| Heating Method | Electromagnetic heating, ceramic heating, heating coils |

| Die Head | Gear die head, hydraulic die head, meshless slag discharge die head |

| Hot Sale Country | Saudi Arabia, Ghana, Kenya, Ethiopia, Iran, Nigeria, Botswana, etc. |

| Warranty Period | 12 momths |

Global Cases Of The Recycling Granulator Machine

Nigeria Customer Feedback Video

The customer from Nigeria wanted to buy the HDPE pelletizing machine, after communication, we learned that their raw material is HDPE, so our sales manager recommended this HDPE granules making machine to the customer. The feedback from the customer is that the machine is running well.

Mozambique Customer Chooses Rigid Plastic Granulator Machine

Our rigid plastic granulator machines are also well used in Mozambique, where customers want to process their hard plastics into recycled plastic pellets for profit.

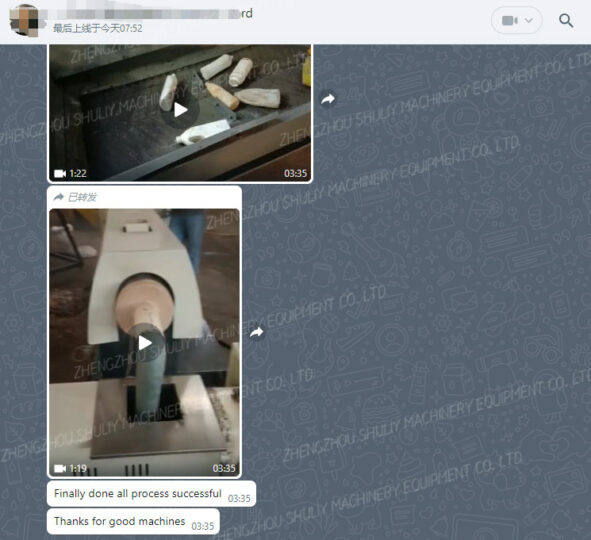

Feedback On HDPE Granules Making Machine In Côte d’Ivoire

Côte d’Ivoire recently gave us feedback showing how well our HDPE granules making machine is working in their factory. The customer stated that the plant was running successfully and thanked us for providing an efficient plastic recycling machine.

For more details: Hard PP PE Pelletizing Line Operates in Côte d’Ivoire

Plastic Granules Manufacturing Plant Cost

If you are interested in our recycling granulator machine and want to get the price of the plastic recycling machine, welcome to leave a message on our website, and we will contact you in time.