The plastic granule cutter is a key piece of equipment in a plastic washing pelletizing line, used to cut plastic strips into pellet form for recycling. When operating a plastic granules cutting machine, some important things need to be noted to ensure the safe and efficient operation of the equipment. In this article, we will introduce the precautions to be taken when using a plastic granule cutter to help users operate the equipment correctly and achieve high-quality plastic pellet cutting.

Confirm Plastic Type and Size

Before operating the plastic pelletizing machine cutter, it is important to confirm the type and size of plastic to be cut. Different types and hardnesses of plastics may require different cutting parameters and tool settings, ensuring that the machine is adjusted correctly for optimum cutting results.

Checking and Maintaining Plastic Granule Cutter Knives

Regularly check the condition of the plastic granules cutting machine knives to ensure that the blades are sharp and well fixed. Dull steel blades can affect cutting efficiency and cut quality, and loose knives can lead to safety hazards. Maintain and replace knives regularly to maintain good cutting results.

Control of Feed Rate

Control the feed rate of the plastic to ensure that it is not too fast or too slow. Too fast a feed rate can lead to overloading and equipment failure, while too slow a feed rate can affect productivity. Adjust the feed rate appropriately according to the type of plastic and cutting requirements to ensure the smooth operation of the equipment.

Shutdown Procedure of Plastic Pelletizing Machine Cutter

Before stopping the plastic pelletizing machine cutter, stop the feed for 15 minutes to ensure that the plastic inside the plastic granule cutter is completely cut. Then switch off the control power supply in the correct sequence to ensure that the machine shuts down safely.

Cleaning and Maintenance

At the end of each day’s work, clean the inside and surrounding areas of the plastic granules cutting machine in a timely manner to remove residual materials and dust and keep the equipment clean and tidy. Perform regular maintenance of the equipment, including cleaning and lubrication, to extend the life of the equipment and keep it in good working condition.

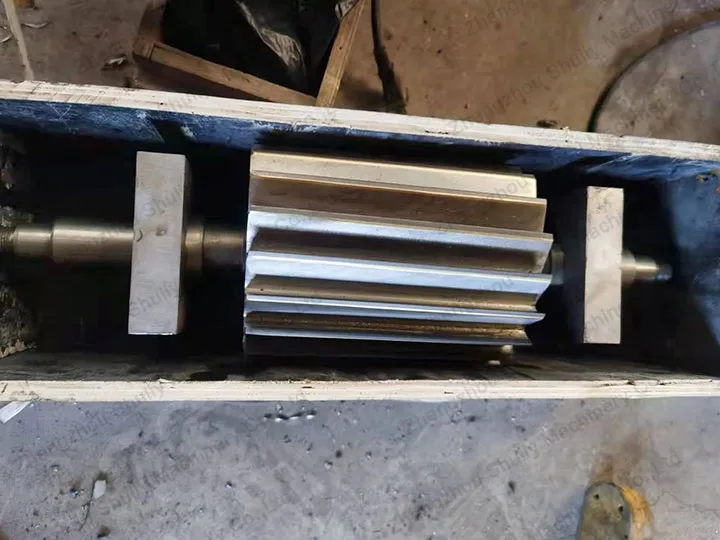

Shuliy’s Plastic Granule Cutter

Following the above precautions can ensure the safe and stable operation of the plastic pelletizing machine cutter and improve production efficiency. Shuliy’s plastic granules cutting machine has excellent performance, an intelligent control system, a high wear-resistant carbide hob to ensure long-lasting use, and an adjustable cutting size to meet different customer needs.