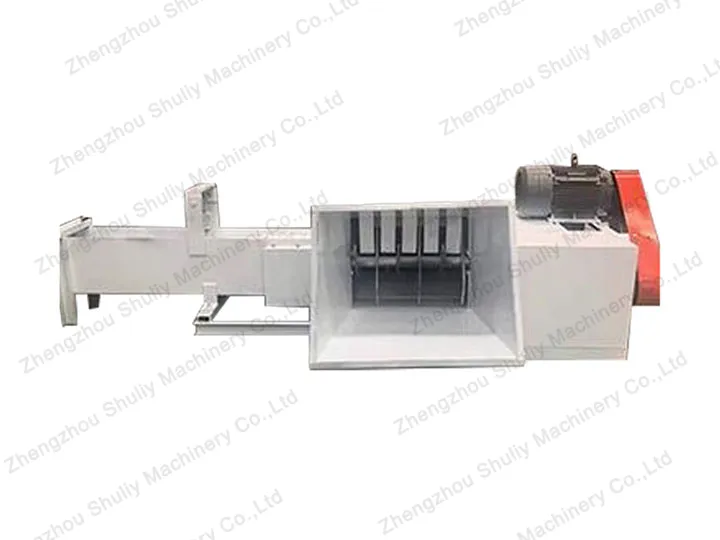

The horizontal EPS foam compactor is used to compress EPS foam, increasing the density and compressing the EPS foam into blocks. This not only greatly reduces the volume of EPS foam, facilitating EPS foam recycling, stacking storage, and transport, but also saves occupied space and transport costs, facilitating foam recycling and improving economic efficiency.

Introduction of Horizontal EPS Foam Compactor

The horizontal EPS foam compactor has the same function as the vertical foam compactor. Its principle is to compress EPS foam into blocks with a screw compression mechanism, which is convenient for customers to transport and generate pellets again.

The inlet of the horizontal EPS foam compactor is flush with the floor. The operator simply sweeps the foam into the inlet with a broom, and the machine has a shredding mechanism inside to break up the foam pieces. The small pieces of foam are then compacted into squares with a compression ratio of up to 40 times to reduce the size of the EPS, facilitate long-distance transport, and reduce storage and transportation costs.

Advantages of Horizontal EPS Foam Compactor

- A large compression ratio of up to 40 times.

- Save storage space, transport, and storage costs.

- The compressed EPS material is easy to pelletize and reuse.

- The feed opening is flush with the floor for easy feeding.

Application of EPS Foam Compactor

The horizontal EPS foam compactor is suitable for extruding various EPE/EPS foam products, such as fast food boxes, insulation boxes, foam packaging materials, pearl cotton, and other waste plastic products. The extruded squares are shown in the picture below.