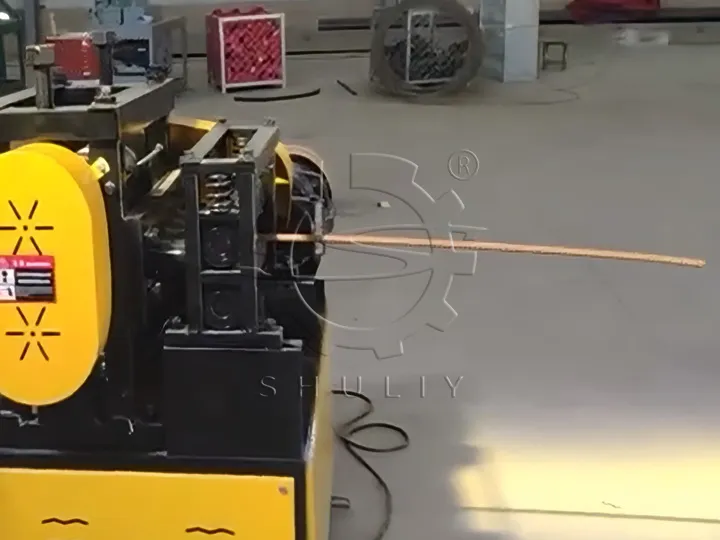

Our rebar straightening machine is the go-to tool for turning your bent or used steel bars into valuable, straight material. Specifically designed for recycling, this machine effortlessly handles waste rebar with diameters from 6mm to 25mm. It’s built with a powerful dual-motor and reducer system, giving you fast, stable performance without the frustration of material jamming. This is the durable, easy-to-use solution your construction site or recycling yard needs.

Why Choose Our Steel Bar Straightening Machine?

You have waste steel. We have the solution. Here’s exactly how our machine helps you work smarter and earn more.

Designed for Waste Steel Bar Recycling

Stop seeing bent rebar as scrap. With this machine, you can quickly straighten piles of used, crooked, or discarded steel bars. Turn that waste into perfectly straight, reusable material for your next project or for profitable resale. It’s a direct way to increase your operational value.

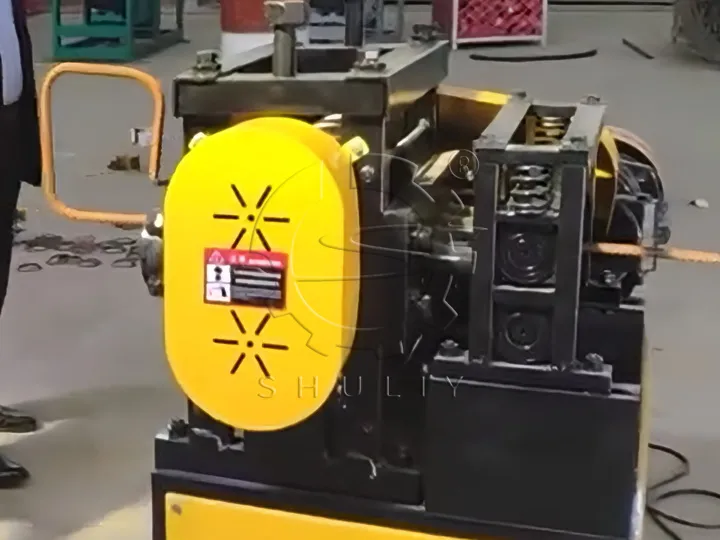

Powerful, Jam-Free Performance

Downtime from jammed material costs you money. Our machine solves this with a dual-motor drive paired with a high-torque reducer. This system ensures consistent power and smooth feeding, effectively preventing jams.

Simple to Use, Ready for Any Job

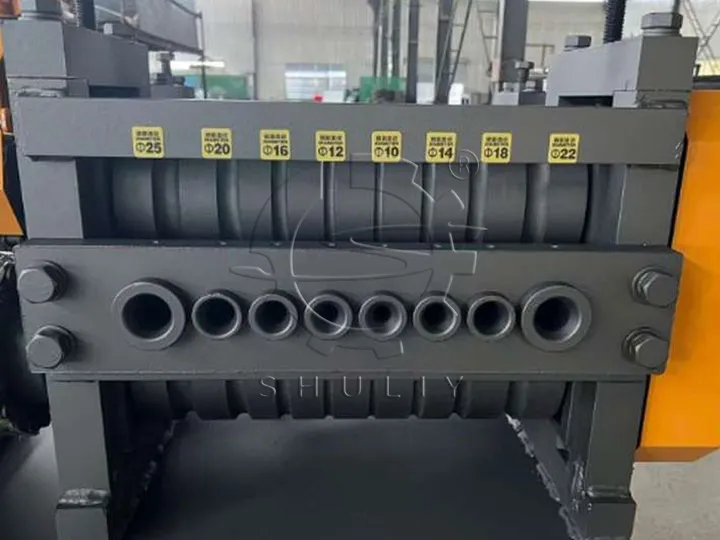

No complex training needed. Each model comes with multiple inlet holes for different rebar diameters. Simply choose the hole that matches your steel bar and feed it in. This versatility means one rebar straightener can handle a wide range of your recycling needs, saving you space and money.

Rebar Straightener Machine Working Video

What Kind of Steel Can You Straighten?

Our rebar straightening machine is built to process the common types of steel you find on job sites and in recycling yards. You can confidently feed it:

- Bent or Used Rebar: Steel bars from construction or demolition projects that have been bent out of shape.

- Threaded Steel (Deformed Bars): The standard crooked or leftover threaded steel bars used for concrete reinforcement.

- Round Steel (Plain Bars): Any plain, smooth round steel bars that need to be straightened for reuse.

- General Waste Steel Bars: Any other scrap or waste steel bars, as long as their diameter is between 6mm and 25mm.

Basically, if you have bent steel bars—whether they are threaded or plain, old or leftover stock—our machine is designed to straighten them. This makes it the single most valuable tool for reclaiming value from your entire steel inventory.

Find Your Perfect Model: Rebar Straightener Specifications

Choose the model that fits your needs. Our rebar straightening machines are available in multiple models to meet your diverse processing requirements.

| Model | Straightening Diameter (mm) | Inlet Holes | Motor Power (kW) | Machine Weight (kg) | Machine Dimension (mm) |

| 6-10 | 6-10mm | 5 Holes | 4 kW | 570 kg | 1100 * 720 * 1150 |

| 6-14 | 6-14mm | 5 Holes | 5.5 kW | 730 kg | 1200 * 790 * 1220 |

| 8-16 | 8-16mm | 5 Holes | 5.5 kW | 750 kg | 1250 * 820 * 1300 |

| 14-25 | 14-25mm | 6 Holes | 15 kW | 980 kg | 1550 * 890 * 1600 |

Who Is This Rebar Straightening Machine For?

Our waste rebar straightening machine is an essential tool for:

- Construction Sites: Immediately straighten and reuse bent steel bars on-site.

- Scrap Metal Recycling Yards: Upgrade your waste steel and significantly increase its value.

- Steel Processing Centers: An efficient first step in your steel bar processing line.

- Precast Factories: Ensure all your steel meets quality standards before casting.

Related Rebar Processing Machines

For customers who need complete rebar processing solutions, we also provide related machines such as the steel ring making machine and the rebar stirrup bending machine. These machines can handle bending, coiling, and forming tasks efficiently, making them ideal complements to your straightening process.

Rebar Straightening Machine for Sale: Get Your Quote Today!

You’ve seen what our machine can do. Now, it’s time to put it to work for your business. We have high-quality, durable rebar straightening machines for sale, ready to boost your efficiency and turn waste material into profit.

Contact our expert team right now. Tell us your needs (like the rebar diameters you work with), and we will provide you with a personalized, no-obligation quote. Let’s find the perfect solution for you!