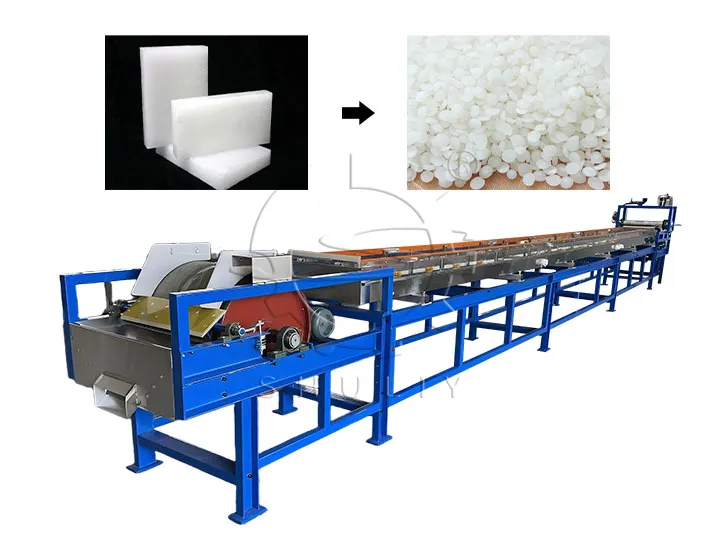

Paraffin wax pastillator is a mature and widely used solution in our long-term cooperation with customers in the wax products, chemical, and personal care industries. It is mainly designed to continuously cool and form molten paraffin wax into uniform pastilles (granules).

During discussions with customers, the most common concerns are equipment stability, raw material adaptability, and how the finished granules will be used downstream. These are also the key factors we focus on when designing and supplying this paraffin wax system.

Key Features of Our Paraffin Wax Pastillator

Multiple Models for Different Production Capacities

Available in various models with production capacities ranging from 50 to 1200 kg/h, suitable for small-scale to industrial-scale operations. Actual output may vary depending on the raw material.

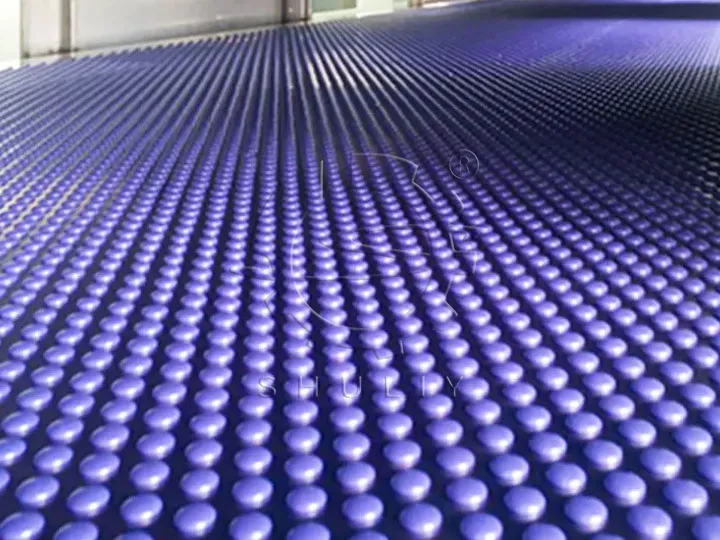

Consistent and Uniform Granule Formation

Capable of continuously producing dust-free, hemispherical granules with diameters of 4–8 mm. The granules are uniform in shape and size, and the particle size can be adjusted according to customer requirements.

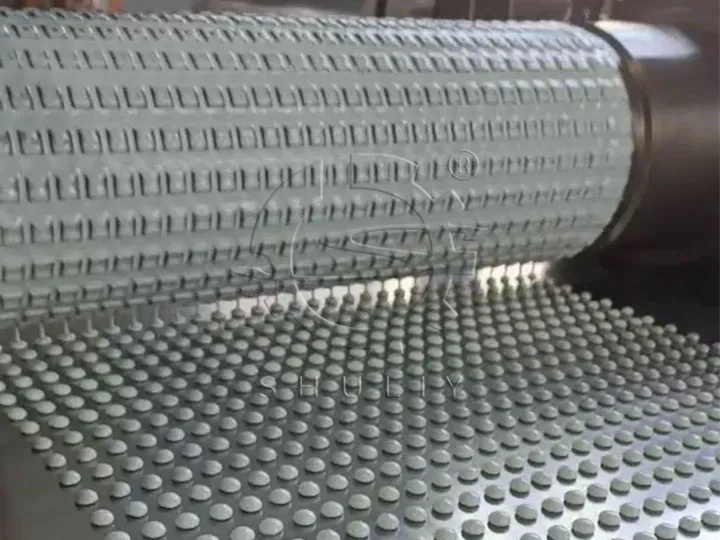

Steel Belt Cooling Technology

Equipped with a moving steel belt combined with a bottom water-spray cooling system, enabling rapid cooling and solidification of molten paraffin wax. This design improves production efficiency while maintaining granule integrity.

Wide Raw Material Compatibility

Designed to process materials with melting points between 50°C and 250°C that can be heated into a liquid state and solidified by cooling, suitable for various waxes and similar materials.

Automated Operation for Stable Performance

A high level of automation reduces manual intervention, ensures consistent granule quality, enhances operational safety, and minimizes downtime and maintenance requirements.

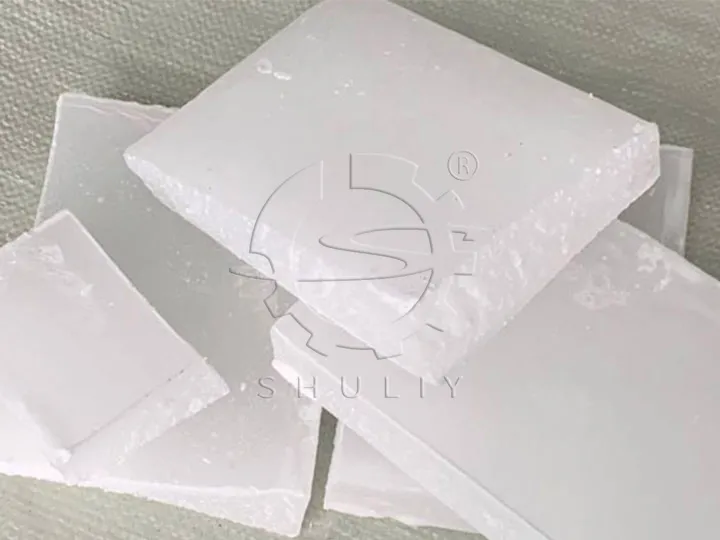

Why Do Customers Choose Paraffin Wax Pastillation?

In practical projects, we see more and more customers shifting from traditional block paraffin wax to granulated or pastillated wax. The reasons are straightforward:

- Granules have good flowability and are easy to meter and feed automatically

- Less breakage and no dust, improving the production environment

- Easier packaging, storage, and transportation

- Uniform appearance, better suited for standardized production

The paraffin wax pastillator is developed based on these real production needs, providing a continuous and stable wax granulation solution, rather than an experimental or small-batch system.

What Can Paraffin Wax Granules Be Used For?

This is one of the most frequently asked questions during the inquiry stage. Based on our project experience, paraffin wax granules produced by a paraffin wax pastillator are highly versatile and can be directly used in a wide range of applications:

- Candle industry: As a basic raw material for candle production, wax granules are ideal for automated melting and dosing systems

- Personal care and cosmetic industry: Used for depilatory wax, care wax, and cosmetic wax products

- Fragrance beads and aroma products: Granular form is convenient for fragrance blending, coloring, and secondary processing

- Foundry industry: Used for casting wax and investment casting processes

- Packaging and coating applications: Moisture-proof wax, coating wax, and industrial protective wax

- Chemical and rubber industry: Used as additives or modified wax materials

During the mixing stage, colorants or functional additives can be added according to customer requirements, ensuring uniform color and consistent performance of the final granules for different downstream applications.

How Does Our Paraffin Wax Pastillator Work?

From a complete production line perspective, this is a continuous and stable paraffin wax pastillation system:

1. Raw Material Melting and Mixing

Paraffin wax is heated and melted in the mixing tank and kept in a uniform molten state. At this stage, pigments or additives can be added based on the final product requirements.

2. Constant-Temperature Transfer

The molten material is transferred to the wax pastillator by a material pump. A thermal oil heater maintains the pipeline temperature to prevent premature solidification during transfer.

3. Pastillation and Forming

The molten wax enters the paraffin wax pastillator head and is evenly deposited through molds onto the cooling system, forming hemispherical wax pastilles.

Typical product size is 4–8 mm, adjustable by controlling the feed rate and the height of the pastillation head.

4. Cooling and Collection

The formed granules are rapidly solidified through a water-cooling system. Most projects use water cooling, while a chiller can be added when higher capacity or more stable cooling performance is required.

Paraffin Wax Pastillator Running Video

Applicable Raw Materials For The Wax Resin Pastillator

Based on current applications, this paraffin wax pastillator can process a wide range of meltable materials, including:

- Various types of paraffin wax (fully refined, semi-refined, industrial grade)

- Rosin and similar resin materials

- Casting wax and depilatory wax

- Fragrance bead raw materials

- Other materials with a melting point between 50–250°C that can be melted and solidified by cooling

As long as the material can be heated into a liquid state and solidified again by cooling, it is generally suitable for this wax granulation line.

Main Equipment Configuration

As a supplier, we focus more on the overall system matching and long-term stability rather than just the main machine:

- Mixing tank (100 / 300 / 500 / 1000 L optional)

- Material pump

- Thermal oil heater (for material and pipeline temperature control)

- Paraffin wax pastillator main unit

- Water pump and water tank

- Chiller (optional, for improved cooling efficiency)

Capacity and Model Selection Suggestions

To meet different production scales, we offer multiple model options:

| Model | SL-W40 | SL-W60 | SL-W100 | SL-W120 | SL-W150 |

| Machine Width | 400 mm | 600 mm | 1000 mm | 1200 mm | 1500 mm |

| Machine Length | 7000 mm | 12000 mm | 14000 mm | 15000 mm | 23000 mm |

| Mold Hole Size | 1.8–2.2 mm | 1.8–2.2 mm | 1.8–2.2 mm | 1.8–2.2 mm | 1.8–2.2 mm |

| Granule Size | 4–8 mm (adjustable) | 4–8 mm (adjustable) | 4–8 mm (adjustable) | 4–8 mm (adjustable) | 4–8 mm (adjustable) |

| Granule Shape | Hemispherical | Hemispherical | Hemispherical | Hemispherical | Hemispherical |

| Paraffin Capacity | 50–100 kg/h | 150–200 kg/h | 300–350 kg/h | 400 kg/h | 600 kg/h |

| Resin Capacity | 100–200 kg/h | 200–300 kg/h | – | 600–800 kg/h | 800–1200 kg/h |

| RD Material Capacity | 100–200 kg/h | 200–300 kg/h | – | 600–800 kg/h | 800–1200 kg/h |

| Motor Power | 5 kW + 1.5 kW | 5 kW + 1.5 kW | 3 kW + 1.5 kW | 5.5 kW + 1.5 kW | 5.5 kW + 1.5 kW |

Contact Us For Paraffin Wax Pastillator Details

As a paraffin wax pastillator supplier, we do not simply provide a machine. Our goal is to ensure that the system truly fits your product applications, whether for candles, fragrance beads, depilatory wax, or casting wax production.

If you are planning to convert paraffin wax into granules or upgrade your existing wax processing line, we can help you define the right equipment configuration and process solution based on your raw materials and application needs.