If your business handles large volumes of scrap metal—whether it’s steel, aluminum, copper, or mixed metals—you’ve probably faced the challenge of storage space, transportation costs, and keeping materials organized. A metal scrap baling machine offers a simple yet effective solution: it compresses loose scrap into compact, uniform bales that are easier to handle, transport, and sell.

As a professional metal recycling equipment supplier, we provide balers designed for a wide range of materials, including scrap steel, car bodies, aluminum waste, beverage cans, stainless steel, copper, metal shavings, aluminum profiles, aluminum turnings, and other non-ferrous metals.

What is a Metal Scrap Baling Machine?

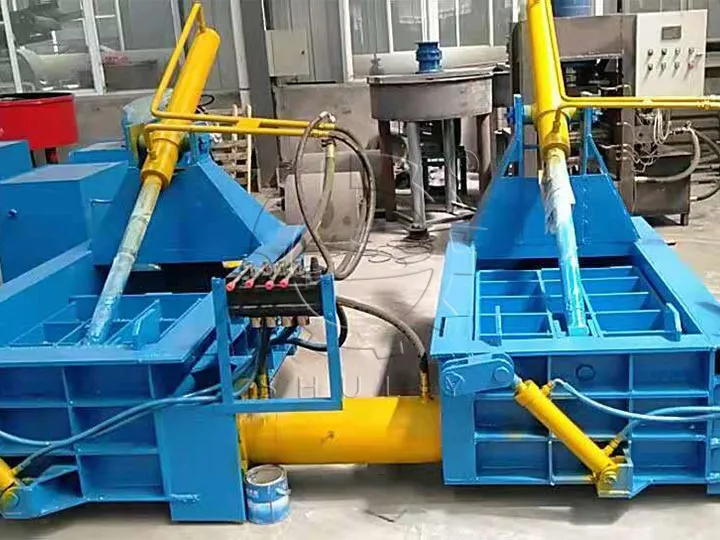

A metal scrap baling press machine, sometimes called a scrap metal compactor or scrap metal baler, uses hydraulic force to compress loose metal into dense, uniform bales. These bales not only save space but also increase the scrap’s value in the recycling market.

Typical materials that can be processed include:

- Steel plates, beams, and structural offcuts

- Old car bodies (whole or dismantled)

- Aluminum waste and profiles

- Beverage cans

- Stainless steel scrap

- Copper wires, pipes, and fittings

- Metal shavings from machining workshops

How Does a Scrap Metal Compactor Works?

Why Choose a Scrap Metal Baler for Your Business?

- Reduce Storage Space – Compress scrap metal by up to 80%.

- Lower Transportation Costs – More material per load means fewer trips.

- Improve Material Handling – Neatly baled scrap is safer and easier to store.

- Increase Scrap Value – Baled scrap is often sold at a better price.

- Versatile Applications – Works with both ferrous and non-ferrous metals.

If your factory or recycling yard has a large amount of loose scrap metal, using a metal scrap baling machine can make storage and management more efficient and organised.

How to Select the Right Metal Scrap Baling Machine

When choosing a baler, consider:

- Daily Processing Volume – Match machine capacity to your scrap load.

- Bale Size & Weight – Fit your transport and smelting requirements.

- Scrap Material Type – Steel, aluminum, copper, or mixed metals.

- Operation Mode – Manual, semi-automatic, or fully automatic.

- Machine Durability – Strong frame, reliable hydraulics, and easy maintenance.

Not sure which model is right for you? Our team can assess your materials, capacity needs, and budget to recommend the best baler for your business.

Our Metal Baler Specifications

Our metal balers come in a wide range of models, with compression forces from 1250 kN to 4000 kN, capable of handling various sizes and weights of scrap metal. The compression chamber dimensions range from 1200×700×600 mm to 3500×3000×1200 mm, while bale sizes vary from 300×300 mm to 600×600 mm, all achieving a density of ≥2000 kg/m³.

Depending on the model, production efficiency can reach 1,200 kg/h to 14,000 kg/h, with cycle times between 100 and 160 seconds. We can provide the most suitable model or offer customized solutions based on the customer’s output, raw material type, and site conditions to ensure efficient and stable baling performance.

After-Sales Support You Can Rely On

We understand that buying a metal scrap baling machine is an investment. That’s why we offer:

- Professional installation and commissioning

- Operator training for safe and efficient use

- Spare parts supply and quick delivery

- Ongoing technical support

Scrap Metal Baler For Sale

A metal scrap baling machine can transform the way you handle scrap metal—saving space, cutting costs, and improving recycling profits. As your partner in metal recycling solutions, we are here to provide reliable equipment and dedicated service from consultation to after-sales support.

You can tell us your waste type, daily processing volume, and desired bale size, and we will recommend a suitable model or customize equipment for you.