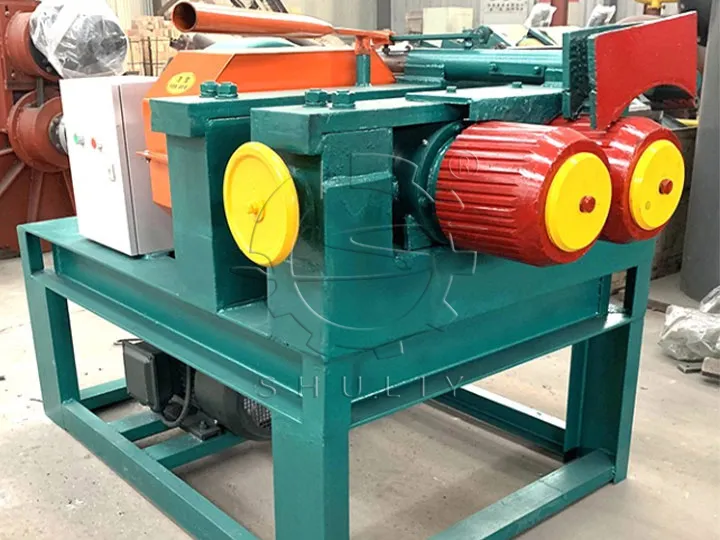

The tire steel wire separator is a machine designed to separate steel wire beads from scrap tyres, for bead sections up to 1200 mm in diameter. It is usually used in conjunction with a tire sidewall cutting machine to separate the steel wire from the rubber of the cut bead section, and is an indispensable part of the waste tyre recycling line.

The Role of the Tire Wire Removal Machine

This equipment applies strong pressure using double rollers rotating and squeezing to effectively separate the steel wire embedded in the tyre bead. The separated steel wire can be recycled as recycled metal, while the rubber part can be sent to the tire shredder for further processing, enhancing the overall resource utilisation rate.

Features & Advantages

- High Separation Efficiency: Strong extrusion force ensures complete and clean separation of steel wires

- Wide Adaptability: Adjustable roller gap to suit various bead thicknesses

- Durable Design: Equipped with wear-resistant alloy rollers for long service life

- Compact Structure: Easy to operate and space-saving

- Customizable Models: Available in different models to handle larger tire sizes as needed

Working Principle of Tire Steel Wire Separator

The tire steel wire separator consists of two high-strength alloy rollers. When in operation, the tire bead is manually fed between the rollers. Once the machine starts, the rollers rotate in synchronization, applying strong compression to the bead. The pressure separates the steel wire from the rubber.

Application of the Steel Wire Separator

- Waste tire recycling centers

- Reclaimed rubber production plants

- Waste tyre recycling plant

Technical Parameters

- Suitable Tire Bead Diameter: ≤1200mm

- Roller Material: Hard alloy steel

- Adjustable Roller Gap: Manually adjustable based on bead thickness

- Motor Power: Configured according to model

- Processing Capacity: 120pcs/h (for reference)