The waste tire recycling line is designed to process used tires into rubber granules or rubber powder. It efficiently separates steel wire and nylon fiber while producing clean and uniform rubber materials suitable for various applications.

Our company offers three processing solutions—semi-automatic, fully automatic, and OTR tire recycling lines—allowing customers to choose according to their tire types, production capacity, and automation requirements. The machines and final product sizes can be customized based on specific needs.

Raw Material and Profitable Final Products from Tire Recycling

The raw materials for the rubber powder production line mainly include discarded passenger car tires, truck tires, and OTR (off-the-road) tires used in engineering vehicles.

Through a series of processing steps, the entire waste tire recycling line efficiently converts waste tires into rubber granules or powder while simultaneously separating the steel wires and nylon fibers.

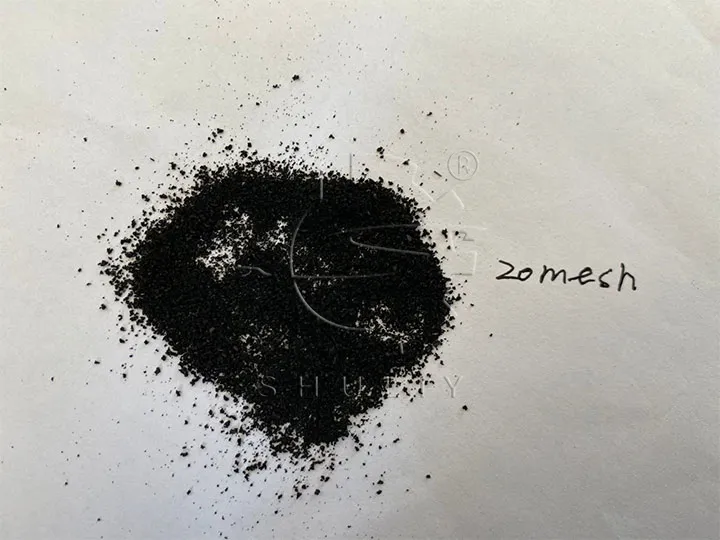

The final particle size of the rubber material can be flexibly adjusted according to customer requirements, making it suitable for a wide range of applications such as rubber floor tiles, running tracks, and reclaimed rubber products.

Features of Waste Tire Recycling Line

- Adjustable Output Size: Rubber size can be customized according to market demand.

- High Purity Output: Equipped with advanced magnetic separation and fiber removal systems, achieving over 99% rubber purity.

- Scalable Configuration: Available in different models to suit small, medium, and large-scale recycling needs.

- Customizable Design: Tailored layout based on your workshop space and production capacity.

Available Recycling Solutions

To meet the diverse needs of our clients, we offer three tire recycling solutions based on automation level and tire size: semi-automatic, fully automatic, and OTR tire recycling lines. Each solution is designed to efficiently convert waste tires into high-purity rubber powder or granules, with flexible configurations to match production goals and plant layouts.

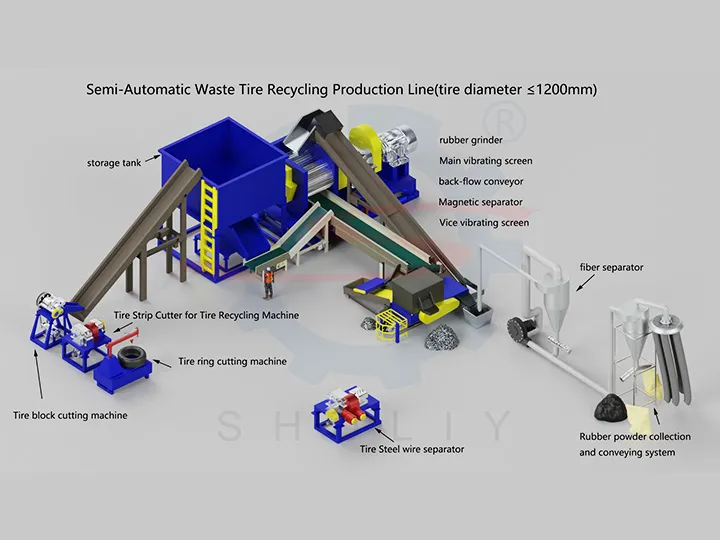

Semi-automatic Rubber Powder Production Line

This configuration is suitable for small to medium-sized recycling operations for the treatment of tyres with a diameter of 1200 mm. Two to three workers are required for the pre-treatment stage. Equipment included:

- Tyre sidewall cutting machine: Cut off the part of the tyre sidewall containing the rim.

- Rubber strip cutter: Cut the tyre into strips.

- Tire block cutter: Cut tyre strips into chunks.

- Tyre bead wire remover machine: Separate the rubber from the steel ring.

- Rubber crusher machine: Grinding of rubber blocks into rubber powder.

- Fiber separator machine: Removal of nylon fibres from rubber powder.

See Our Semi-automatic Waste Tire Recycling Line in Action

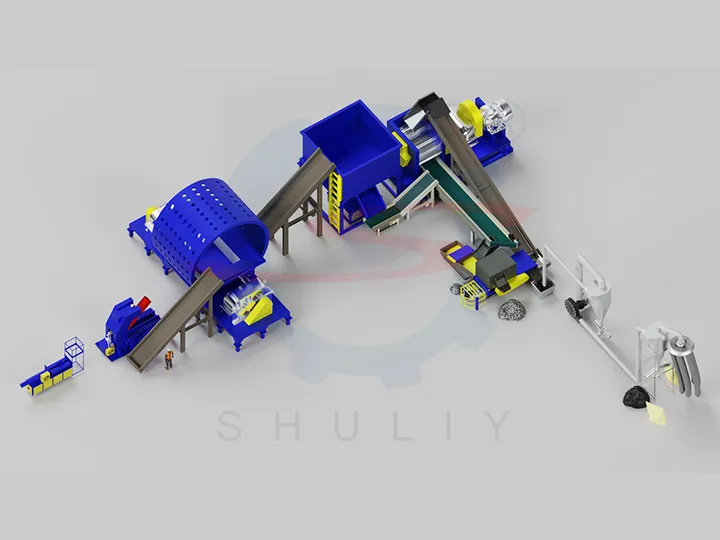

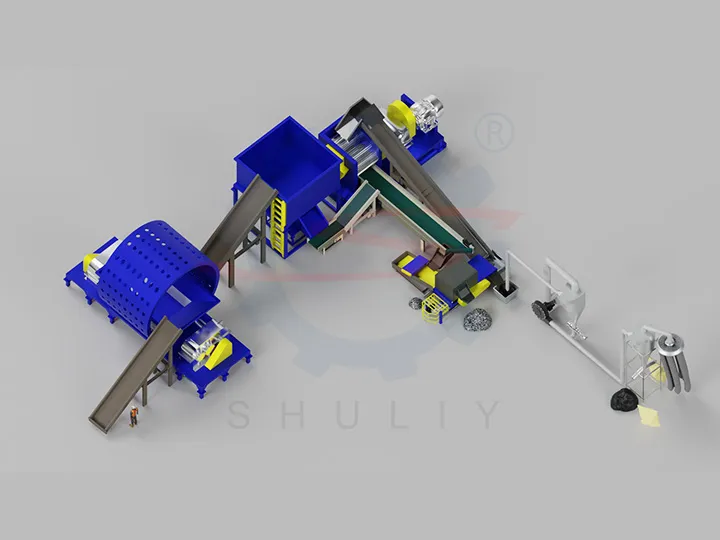

Fully Automatic Waste Tire Recycling Line

This solution is suitable for processing car and truck tires with a diameter less than 1200mm. It includes three customizable configurations:

- Tire debeader: Use the hydraulic system to pull out the steel rim from the tyre.

- Tire cutting machine: Cut the tyre into three sections for easy subsequent shredding.

- Tire shredding machine: Shred the tyres into small pieces of 3-5cm, the output size can be adjusted according to the customer’s demand.

- Rubber crusher machine

- Fiber separator machine

- Tire Steel Wire Separator and Cutting Machine: Remove the part of the tire containing the rim on both sides while cutting off the other part of the tire.

- Tire bead wire remover machine

- Tire shredding machine

- Rubber crusher machine

- Fiber separator machine

- Tire shredding machine

- Rubber crusher machine

- Fiber separator machine

This solution is suitable for tyres that have already been pre-treated, focusing on efficient shredding and fine screening.

Video of Fully Automatic Tire Recycling Line

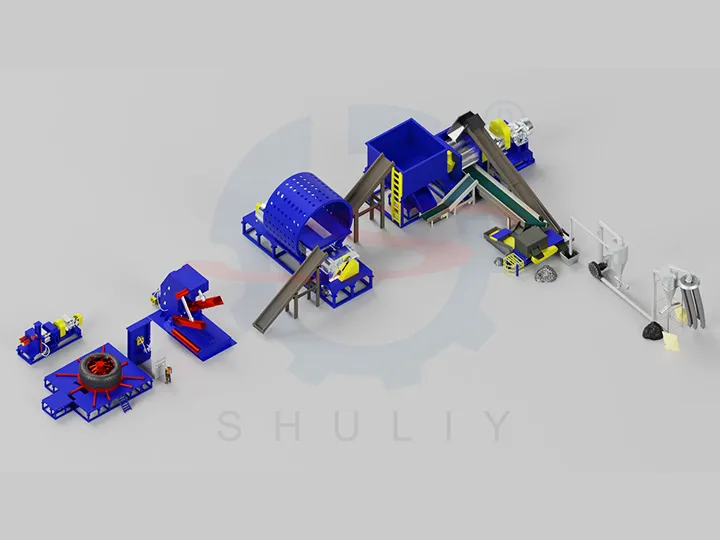

OTR Waste Tire Recycling Line

Specially developed for off-the-road (OTR) tires used in mining and construction vehicles, this waste tire recycling line handles larger tire sizes with two configuration options:

For tire diameters between 1800–4000mm

- OTR debeader: Remove steel rims from OTR tires.

- OTR cutter: The tyre with the rim removed is cut into three sections for subsequent shredding.

- Tire shredder machine (Model 1200 or larger)

- Rubber crusher (Model 450 or above)

- Fiber separator

For tires above 2100mm in diameter

- OTR dismantling machine: The tyre is cut and separated into 4-6 parts, such as bead opening, tread, and top of the tyre, for further processing.

- OTR cutter machine

- OTR steel wire separator: Separate rubber and steel rings.

- Tire shredder machine (Model 1200 or larger)

- Rubber crusher (Model 450 or above)

- Fiber separator

Rubber Powder Production Line: Models & Specifications

The Shuliy waste tire recycling line is a complete, integrated system designed to convert scrap tires into high-purity rubber powder or rubber granules.Multiple production solutions, suitable for a wide range of industrial applications.

To cater to diverse production scales and market demands, we offer several models. The production capacity of each line is determined by the model selected and the desired fineness (mesh size) of the rubber powder. Please consult the specification table below to find the model that best matches your business’s capacity and output requirements.

| Model | Capacity (kg/h) by Final Product Fineness | |||

| 10 mesh (2.5mm) | 20 mesh (1.25mm) | 30 mesh (0.83mm) | 40 mesh (0.63mm) | |

| SL-350 | 250-300 | 180-230 | 150-210 | 80-120 |

| SL-400 | 400-500 | 300-350 | 240-280 | 150-175 |

| SL-450 | 500-600 | 400-500 | 350-450 | 200-250 |

| SL-560 | 900-1000 | 600-700 | 450-550 | 300-350 |

| SL-560D | 1500-1600 | 1200-1300 | 1000-1100 | 800-900 |

| SL-660 | 2100-2300 | 1600-1700 | 1200-1300 | 900-1000 |

Welcoming International Clients & Exporting Worldwide

Shuliy Machinery’s professional expertise and exceptional quality in the tire recycling field have attracted clients from all over the world. We have been honored to welcome customers from countries such as Australia, Kenya, and Belgium for factory tours. During their visits, clients witnessed our advanced manufacturing processes, stringent quality control systems, and engaged in in-depth technical discussions with our engineers about equipment performance and customized solutions. These visits not only strengthened mutual trust but also laid a solid foundation for future successful collaborations.

This client trust is the cornerstone of our global expansion. Today, our advanced and efficient tire recycling lines have been successfully shipped to and are operating stably in numerous countries and regions worldwide. Our equipment has been exported to nations including the USA, India, South Africa, Australia, Canada, and Qatar, helping local clients transform waste tires into high-value recycled resources and achieving significant economic and environmental benefits.

No matter where you are, we sincerely invite you to contact us. Let’s discuss how our globally-proven tire recycling solutions can turn your waste management challenges into a successful business venture.

FAQs of Waste Tire Recycling Line

What types of tires can be processed in a tyre recycling line?

Thewaste tire recycling line is suitable for processing passenger car tires, truck tires, agricultural tires, and OTR tires. Different solutions are available for different tire sizes.

Can the output size be adjusted?

Yes. We can adjust the size of the rubber powder or granules according to customer requirements to meet various application needs.

Do you offer customized solutions?

Yes. We provide tailored configurations based on your plant layout, production capacity, and automation level.

What is the production capacity?

Capacity ranges from 80 kg/h to 2300 kg/h, depending on the configuration. We can recommend suitable models based on your requirements.

What are the end products used for?

The rubber powder or granules can be used for rubber tiles, running tracks, shock-absorbing mats, reclaimed rubber products, etc.

Do you provide installation and after-sales service?

Yes. We offer installation guidance, remote technical support, spare parts supply, and full after-sales service.

Start Your Profitable Recycling Business: Get Your Custom Solution & Quote

You’ve seen how our advanced waste tire recycling line transforms waste tires into a high-value commodity. Now, it’s time to turn this leading technology into your business success.

We understand that every great project begins with a precise plan and a reliable partner. Don’t let questions about machine prices, profit analysis, or plant layout hold you back. Our team of experts is ready to provide you with a one-on-one, no-obligation consultation.

Contact us today to receive a FREE package, including:

- Customized Machine Configuration: We’ll recommend the perfect model based on your raw materials and desired capacity.

- A Detailed Project Quotation: A complete list of equipment, prices, and technical specifications.

- Comprehensive Technical Support: Get answers to all your questions about installation, operation, and maintenance.

Simply fill out the form or contact us directly via WhatsApp.