The eddy current separator is an indispensable key sorting machine in a thermal break aluminum recycling line. When communicating with thermal break aluminum recycling customers, we are often asked the same question: how can aluminum, copper, plastics, and iron be separated efficiently while keeping sorting performance stable and labor costs under control?

In a mature thermal break aluminum crushing and separation line, the aluminium eddy current is exactly the core equipment that solves this challenge.

A Separation Strategy Based on the Characteristics of Thermal Break Aluminum

Thermal break aluminum profiles have a complex structure. They are typically composed of aluminum profiles, plastic insulation strips, and a small amount of steel parts or screws. Crushing alone is not enough to achieve effective recycling—the real determinant of recycling value lies in precise downstream separation.

Based on our project experience, the eddy current separator mainly performs the following tasks:

- Effectively separating crushed aluminum from plastic insulation strips

- Precisely sorting non-ferrous metals after the ferrous removal stage

- Providing clean material for subsequent polishing, rust removal, and packing

This is why thermal break aluminum recycling customers often pay close attention to the configuration and performance of the eddy current magnetic separator.

Working Video of The Copper-aluminum Separator

Typical Configuration of a Thermal Break Aluminum Crushing and Separation Line

For thermal break aluminum recycling, we usually recommend the following process flow:

Metal Shredder → Metal Crusher → Eddy Current Separator → Dry Polishing Machine (Polishing & De-oxidation)

- Metal shredder: Performs primary shredding of long thermal break aluminum profiles

- Metal crusher: Further liberates aluminum, plastics, and attached materials

- Eddy current separator: Automatically separates aluminum, copper, plastics, and other materials

- Dry polishing machine: Polishes the separated aluminum and removes oxide layers to improve final product quality

This aluminum crushing and sorting line has been running stably in multiple projects and is suitable for continuous, large-scale recycling operations.

Not Only for Thermal Break Aluminum, but Also Suitable for Various Complex Mixed Materials

Although this eddy current separator aluminium is widely and successfully used in thermal break aluminum recycling lines, in practical projects we also configure it for customers in many other mixed-material separation applications.

After upstream shredding and crushing, the machine is equally suitable for sorting the following materials:

- Recovery of non-ferrous metals from municipal solid waste and industrial residues

- Separation of copper and aluminum from crushed electronic waste and PCB scrap

- Processing of construction waste such as discarded plastic windows, doors, and thermal break aluminum

- Metal sorting from shredded end-of-life vehicles

- Automatic separation of mixed non-ferrous metals such as copper and aluminum

Based on our project experience, as long as the materials are sufficiently liberated and the particle size falls within a reasonable range, the eddy current separator can deliver stable and reliable separation performance.

This is why many customers, when planning recycling lines, prefer to use this equipment as a general-purpose non-ferrous metal separation unit, allowing it to be flexibly applied across different material processing projects.

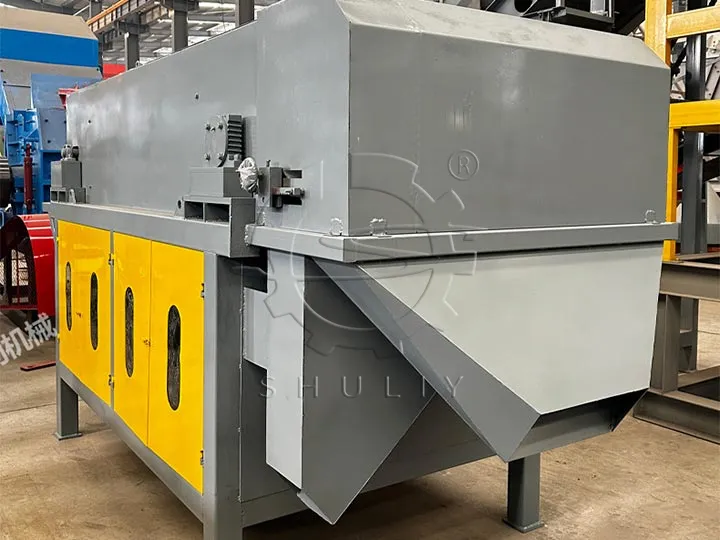

Four Discharge Outlets Designed for Thermal Break Aluminum Sorting

In thermal break aluminum applications, material categories are clear but tightly mixed. This eddy current magnetic separator adopts a four-outlet discharge design, allowing customers to obtain usable materials directly:

- Plastic outlet: Mainly thermal break insulation strips

- Ferrous outlet: Residual steel parts and screws

- Aluminum & copper outlet: High-value non-ferrous metals

- Other impurities outlet: For centralized handling

This discharge structure significantly reduces the need for downstream manual sorting.

Separation Principle and Structural Advantages

From a working principle perspective, the copper-aluminum separator uses the eddy current effect generated by non-ferrous metals in an alternating magnetic field to achieve automatic separation of aluminum and plastics. It is a purely physical separation process with no wastewater or exhaust gas.

Combined with the characteristics of thermal break aluminum, the equipment offers the following structural advantages:

- Permanent NdFeB magnetic rotor with stable magnetic force for long-term operation

- Eccentric magnetic rotor design with adjustable center position to suit different crushed particle sizes

- Controllable forward / reverse rotation of the magnetic rotor to adapt to different sizes of thermal break aluminum fragments

- Good separation performance for thermal break aluminum particles above 2 mm

- Magnetic system protection design to ensure safety during high-speed operation

All these configurations are optimized specifically for thermal break aluminum recycling conditions.

Why Thermal Break Aluminum Recyclers Are Moving Away from Manual Sorting

Compared with traditional manual sorting, eddy current separators show very clear advantages in thermal break aluminum recycling:

- High sorting speed, suitable for large-scale recycling

- Stable separation results with higher aluminum purity

- High automation level, significantly reducing labor costs

- Seamless integration into complete thermal break aluminum recycling lines

- Wide adaptability to different particle sizes

For customers aiming to improve recycling efficiency and final product quality, this is a more sustainable and reliable solution.

Multiple Models to Match Different Processing Capacities

For thermal break aluminum recycling projects of different scales, we offer multiple eddy current separator models with processing capacities ranging from 500 to 5 tons per hour.

The specific model selection is determined based on material condition, crushing size, and target output.

From Equipment Supply to Complete Thermal Break Aluminum Solutions

We do not simply supply an eddy current separator. Instead, we aim to design a suitable complete solution based on your thermal break aluminum material characteristics, target capacity, and on-site conditions.

If you are planning or upgrading a thermal break aluminum recycling project, feel free to contact us with your actual requirements. We will provide appropriate equipment selection and professional separation solution recommendations.