A CNC pipe bending machine is an advanced automated tube-bending solution designed for high-precision forming of metal pipes. Our CNC bending machines cover a wide processing range from 10 mm to 100 mm, suitable for round tubes, square tubes, and oval tubes.

Depending on the model, the bending capacity includes 10–24 mm, 20–51 mm, 30–76 mm, and 40–100 mm, meeting both light-duty thin-wall tube processing and heavy-duty thick-wall tube bending needs. Equipped with a high-precision CNC control system, the machine enables continuous multi-angle and 3D tube bending, making it ideal for automotive manufacturing, shipbuilding pipelines, fitness equipment, HVAC systems, and more.

What Is a CNC Pipe Bending Machine?

A CNC pipe bending machine uses servo motors or hydraulic systems to control pipe feeding, rotation, and bending. These three motions are coordinated by the CNC controller to ensure that each bending angle, radius, and length is completed precisely. Compared with manual and semi-automatic machines, a CNC model offers higher accuracy, faster speed, and full automation, making it ideal for mass production and complex 3D tube forming.

Main Features and Advantages of CNC Pipe Bender

Wide Model Range for Multiple Tube Diameters

The complete model lineup covers pipe diameters from 10–100 mm. This allows the machine to meet requirements from refrigeration tubes to automotive exhaust pipes and structural pipelines.

Suitable for Various Wall Thicknesses and Strength Requirements

Depending on the model, the machines handle 1–6 mm wall thicknesses.

Especially Model 100, capable of bending 2–6 mm thick-wall pipes, is ideal for heavy-load and high-pressure applications.

High-Precision Bending with 0–180° Angle Range

All models support 0–180° bending, and with CNC control, they are capable of multi-angle, continuous, and complex spatial bending.

Widely Used in Multiple Industries

Suitable for aerospace, automotive, shipbuilding, petrochemical pipelines, fitness equipment, HVAC tubing, and more—covering everything from thin-walled precision tubes to structural pipe components.

Why Choose Our CNC Pipe Bending Machines?

- Complete model range for 10–100 mm pipe diameters

- Capable of bending both thin-wall precision tubes and heavy thick-wall pipes

- High-power motor options for industrial long-term production

- Supports round, square, oval, and customized profiles

- Mold customization and bending sample testing available

Related Equipment You May Also Be Interested In

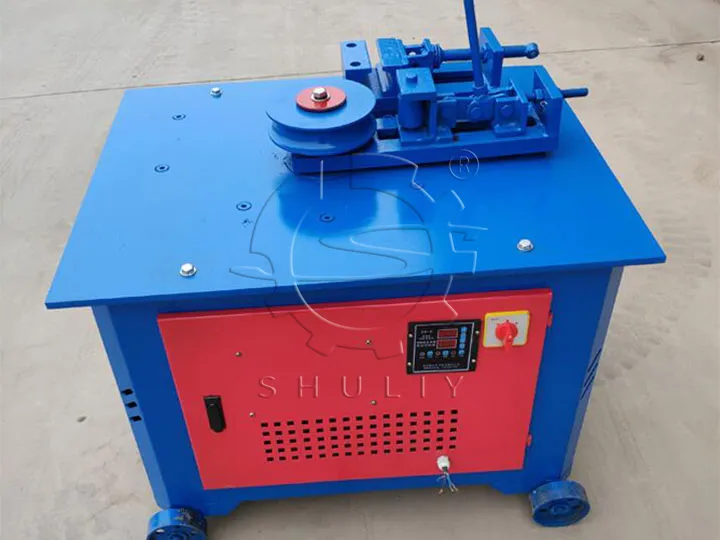

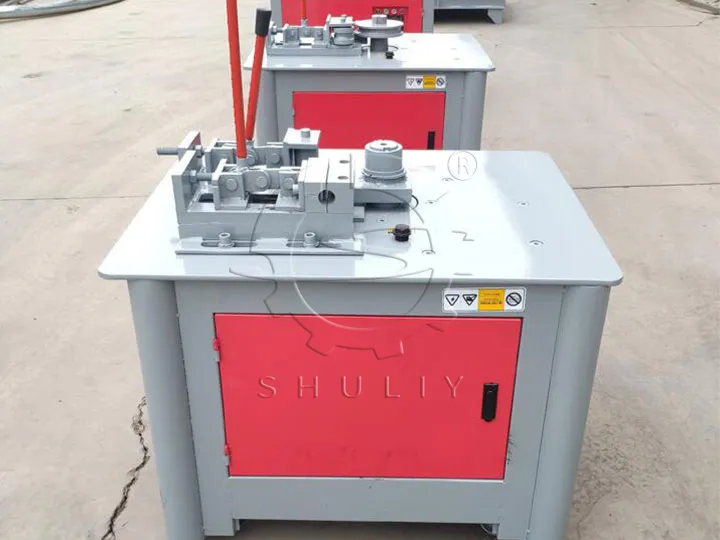

In addition to CNC pipe bending machines, many customers involved in metal tube and bar processing also work with various steel bar forming machines. Commonly used equipment includes the rebar straightening machine, which is designed for straightening coil or deformed steel bars; the rebar spiral bending machine, used for forming circular or spiral shapes; and the rebar bending machine, suitable for multiple angle bending tasks on construction steel bars. If your production requires both pipe fabrication and steel bar forming, these machines can further expand your processing capabilities and help you handle a wider range of metal materials.

Get a Quote for CNC Pipe Bending Machine

If you are looking for a reliable CNC Pipe Bending Machine for your metal tube or steel bar processing project, feel free to contact us. We will recommend the most suitable model and send you a professional quotation.