Mstari wa uzalishaji wa mabenzi ya barafu kavu ni suluhisho kamili na endelevu la uzalishaji tunaowapa wateja wanaohitaji utengenezaji thabiti na wa ufanisi wa mabenzi ya barafu kavu. Kuanzia pelletizing ya barafu kavu hadi kubandika mabenzi, kufuatia na usafirishaji na ufungaji, kila hatua ya mstari imeundwa kwa kuzingatia uaminifu, urahisi wa uendeshaji, na uwezo wa kupanua. Kama muuzaji, msisitizo wetu siyo tu kwa vifaa wenyewe, bali kama mstari huu wa uzalishaji unakidhi mahitaji yako ya uwezo, mazingira ya matumizi, na gharama za uendeshaji za muda mrefu.

Kwa nini Chagua Mstari Kamili wa Utengenezaji wa Mabenzi ya Barafu Kavu?

Katika mawasiliano yetu na wateja, mara nyingi tunagundua kuwa watumiaji wengi awali huzingatia tu mashine moja ya kubandika mabenzi ya barafu kavu. Hii inaweza kusababisha matatizo kama vile muunganisho mbaya wa mchakato, gharama kubwa za kazi, na ubora usio thabiti wa mabenzi.

Kwa sababu hii, kwa kawaida tunapendekeza mstari kamili wa uzalishaji wa mabenzi ya barafu kavu, unaojumuisha pelletizing, uundaji wa mabenzi, usafirishaji, na ufungaji kuwa mfumo mmoja wa ushirikiano. Hii inahakikisha mtiririko mzuri wa malighafi, pato thabiti, na udhibiti bora wa uzalishaji kwa ujumla.

Video ya Operesheni ya Kiwanda cha Utengenezaji wa Barafu Kavu

Pelletizer ya Barafu Kavu: Ugavi wa Malighafi Imara kwa Mstari wa Utengenezaji

Jukumu la Mchakato wa Pelletizing

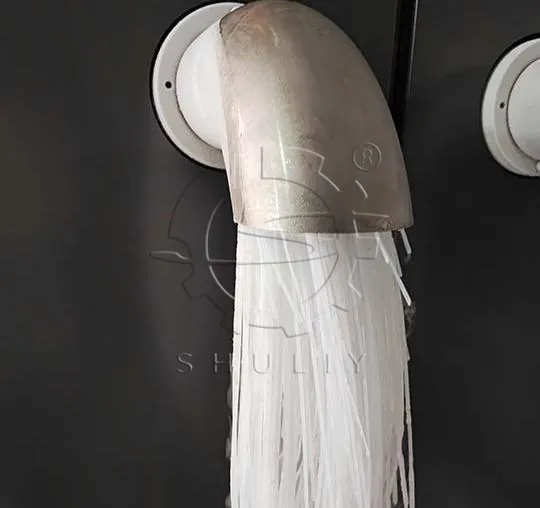

Hatua ya kwanza ya kiwanda cha utengenezaji wa barafu kavu ni pelletizer ya barafu kavu, ambayo hubadilisha CO₂ ya kioevu kuwa pellets za barafu kavu zinazolingana. Hatua hii ina athari moja kwa moja kwa unene wa mabenzi na ubora wa uundaji katika mchakato wa kubandika unaofuata.

Vitu Muhimu vya Kuzingatia Wakati wa Kuchagua Pelletizer

- Saizi sawa ya pellet kwa uundaji wa mabenzi thabiti

- Matokeo ya mara kwa mara ili kuendana na uwezo wa mashine ya mabenzi

- Muundo wa kufunga ili kupunguza upotevu wa sublimation ya barafu kavu

Kwa wateja wenye mahitaji tofauti ya uwezo, tunasaidia kuchagua mfano unaofaa ili kuepuka utendaji mdogo na kupita kiasi kwa sababu zisizo za lazima.

Kibandika cha Mabenzi ya Barafu Kavu: Kunyanyua Pellet kuwa Mabenzi Imara ya Barafu Kavu

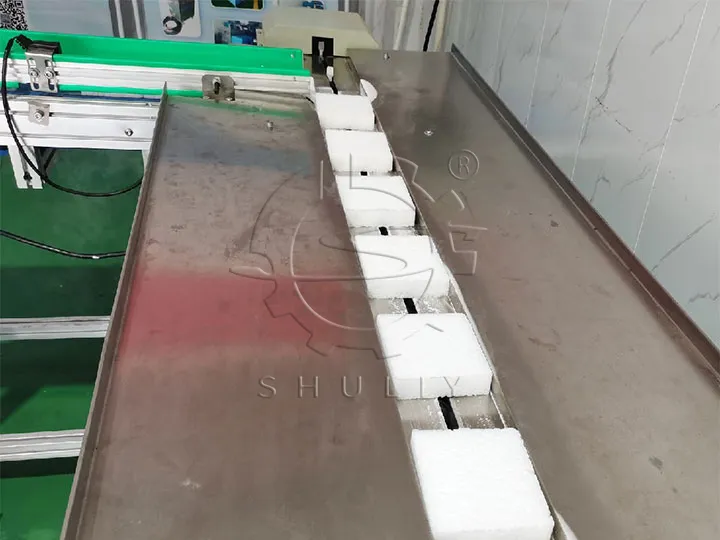

Mchakato wa Kuunda Mabenzi

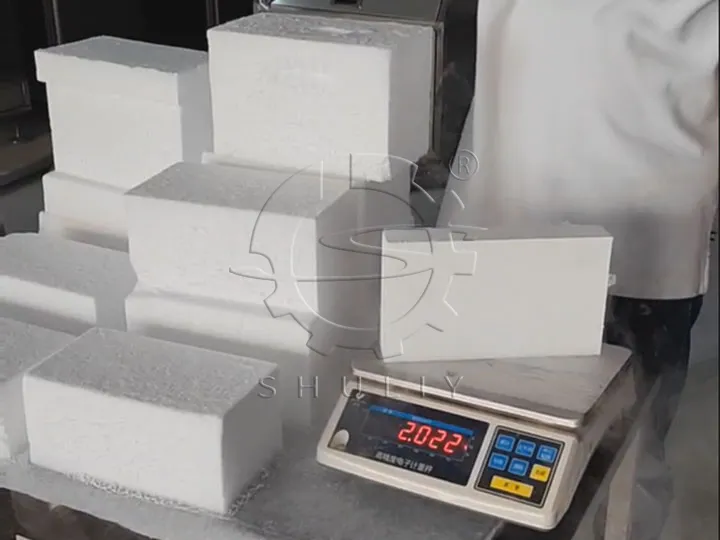

Pellet za barafu kavu zinapelekwa kwenye mashine ya kubandika mabenzi, ambapo zinashinikizwa kwa shinikizo kubwa kuwa mabenzi imara ya barafu kavu. Saizi, unene, na uzito wa mabenzi unaweza kurekebishwa kulingana na mahitaji yako maalum ya matumizi.

Shaka za Wateja Wanaoshiriki

- Mara kwa mara ya unene wa mabenzi

- Rahisi wa kubadilisha mold

- Uwezo wa kubadilika kwa saizi tofauti za mabenzi

Wakati wa kubuni mstari wa uzalishaji wa mabenzi ya barafu kavu, tunathibitisha maelezo ya bidhaa mapema ili kuhakikisha uendeshaji wa muda mrefu wa mabenzi.

Mfumo wa Usafirishaji: Kuunganisha Mchakato Kila na Kupunguza Usafirishaji wa Mikono

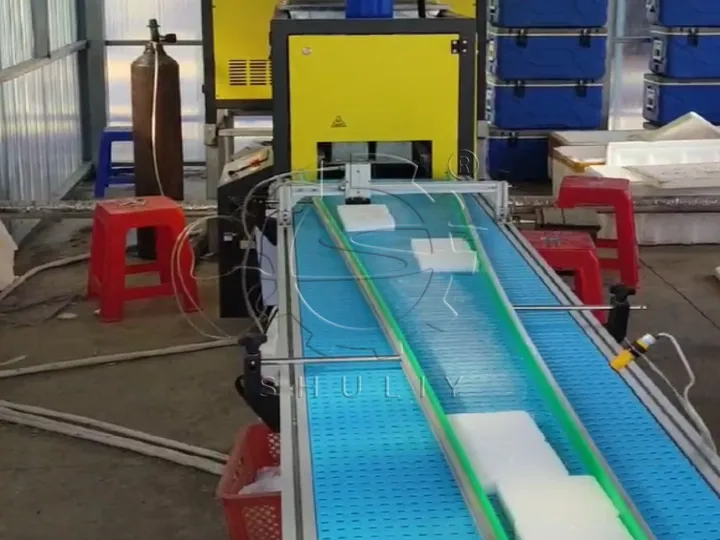

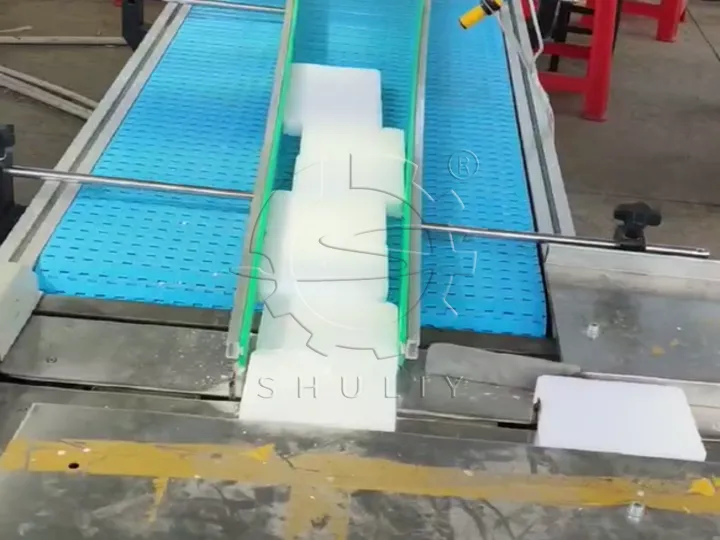

Baada ya kuunda kizuizi, kizuizi cha barafu kavu kinahamishiwa kwa hatua inayofuata kupitia mfumo wa usafirishaji unaolingana na joto la chini. Ingawa sehemu hii haijaunda moja kwa moja bidhaa, ina jukumu muhimu katika ufanisi wa jumla wa uzalishaji.

Manufaa ya Mfumo wa Usafirishaji

- Kupunguza usafirishaji wa mikono na kuboresha usalama

- Muda mfupi wa kuonyeshwa, kupunguza upotezaji wa sublimation

- Muunganisho mzuri na mfumo wa ufungaji

Tunabuni mipangilio ya usafirishaji wa moja kwa moja au wa mzunguko kulingana na nafasi ya warsha yako na hali za tovuti.

Mfumo wa Ufungaji: Kuboresha Uwezo wa Hifadhi na Usafirishaji

Jukumu la Ufungaji katika Mstari wa Uzalishaji wa Kizuizi cha Barafu Kavu

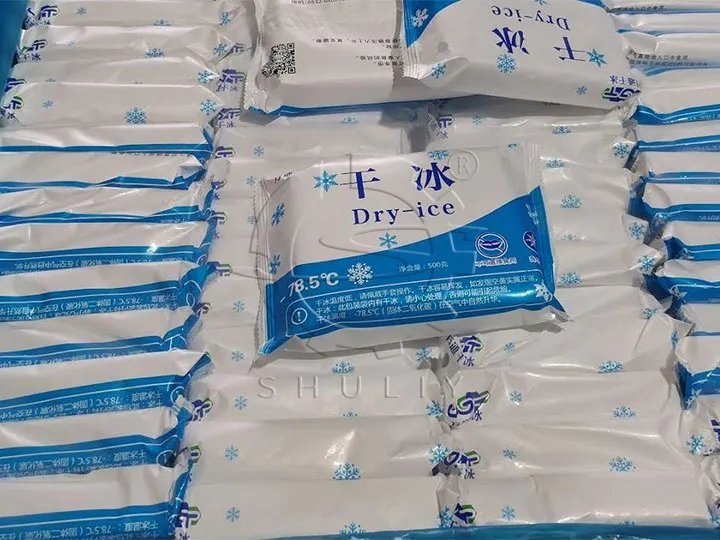

Mara kizuizi cha barafu kavu kinapoundwa, kinapaswa kufungashwa haraka iwezekanavyo ili kupunguza sublimation. Mfumo wa ufungaji unaweza kuwekwa kama ufungaji wa semi-automated au wa msaada wa mkono, kulingana na mahitaji yako ya kiutendaji.

Nyanja za matumizi za kawaida

- Usafirishaji wa mnyororo baridi kwa chakula

- Hifadhi ya baridi ya dawa

- Kupooza viwandani na usafi

Tunasaidia wateja kuchagua suluhisho la ufungaji linalofaa kulingana na hali zao maalum za matumizi.

Manufaa Makubwa ya Mstari wa Uzalishaji wa Kizuizi cha Barafu Kavu

Kutoka kwa mtengenezaji wa mashine za barafu kavu, mstari mzuri wa uzalishaji wa kizuizi cha barafu kavu unapaswa kutoa:

- Mchakato wazi wa mtiririko na vifaa vinavyolingana vizuri

- Uwezo unaoweza kupanuliwa kwa miradi tofauti

- Operesheni rahisi na matengenezo rahisi

- Vipengele muhimu vilivyoundwa kwa matumizi ya joto la chini, kwa muda mrefu

Hizi pia ni pointi kuu tunazingatia wakati wa kupanga mistari ya uzalishaji kwa wateja wetu.

Ni kwa nani Mstari huu wa Utengenezaji wa Barafu Kavu Unafaa?

Mstari wa Uzalishaji wa Kizuizi cha Barafu Kavu ni hasa unafaa ikiwa wewe:

- Panga uzalishaji wa kizuizi cha barafu kavu wa muda mrefu na wa kuendelea

- Hitaji la ukubwa wa kizuizi na unene unaoendelea

- Taka kupunguza uwekezaji wa kazi na kuboresha ufanisi

- Unajiandaa kupanua uwezo au kuingia kwenye masoko mapya ya matumizi

Wasiliana Nasi kwa Mstari wa Uzalishaji wa Kizuizi cha Barafu Kavu Uliobinafsishwa kwa Mahitaji Yako

Kila mteja ana malengo tofauti ya uzalishaji, hali za nafasi, na bajeti. Badala ya kutoa mfano wa kudumu, tunazingatia kutoa mstari wa uzalishaji wa kizuizi cha barafu kavu unaolingana na mahitaji halisi yako.

Wasiliana nasi leo kujadili uwezo wako wa lengo, specifications za kizuizi cha barafu kavu, na nyanja za matumizi. Tutakusaidia kujenga suluhisho la uzalishaji wa kizuizi cha barafu kavu linalofaa na la kuaminika.