Lini produksi nampan telur adalah sistem yang sangat efisien dan otomatis yang dirancang untuk produksi massal berbagai produk cetakan pulp, termasuk nampan telur, nampan buah, tempat gelas, penyangga sepatu, dan kemasan dalam untuk produk elektronik. Lini lengkap mencakup beberapa proses, termasuk penggilingan, pembentukan, pemanasan, pengeringan, dan pengangkutan.

Dengan kapasitas output yang berkisar antara 1.000 hingga 8.000 potong per jam, ini memenuhi kebutuhan pelanggan dari berbagai skala produksi. Kami menawarkan berbagai model dan opsi konfigurasi, termasuk sistem semi-otomatis dan otomatis sepenuhnya, semuanya mendukung solusi yang disesuaikan. Baik itu ukuran cetakan, tata letak jalur produksi, atau proses pembentukan, kami menyesuaikan setiap pengaturan dengan kebutuhan spesifik pelanggan, menjadikannya cocok untuk berbagai aplikasi pengemasan.

Fungsi Peralatan Baki Telur

Fungsi utama dari lini produksi baki telur adalah untuk mengubah berbagai jenis kertas bekas menjadi produk cetakan pulp yang praktis. Melalui proses seperti pengolahan pulp, pembentukan, dan pengeringan, sistem ini memanfaatkan kertas sebagai bahan baku.

Ini memprosesnya dengan peralatan otomatis untuk menghasilkan produk jadi yang stabil secara struktural, menyerap guncangan, dan tahan tekanan. Produk-produk ini banyak digunakan dalam kemasan makanan, barang sehari-hari, dan kemasan industri, secara efektif meningkatkan nilai kertas bekas dan menawarkan solusi kemasan cetakan yang dapat diandalkan.

Video Operasi Jalur Produksi Tray Telur

Bahan Baku Termasuk:

- Koran bekas

- Kertas buku

- Kotak kardus

- Serpihan kertas

- Kardus

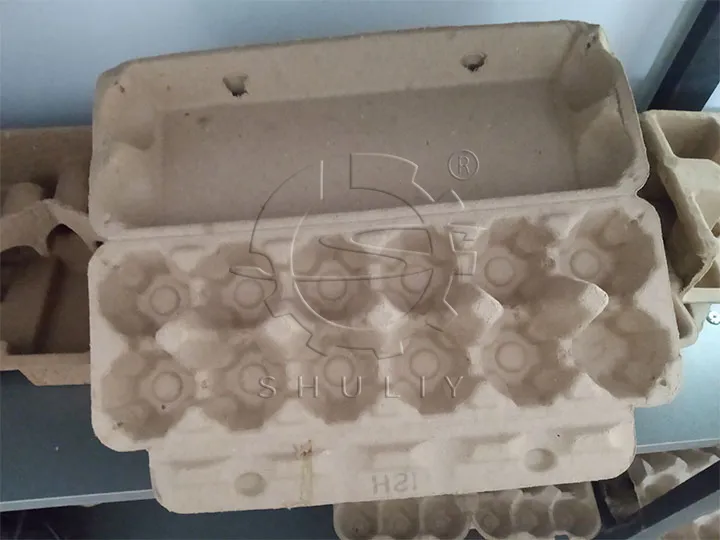

Produk Jadi Termasuk tetapi Tidak Terbatas pada:

- Tempat telur

- Tempat buah

- Dukungan dalam industri

- Tempat gelas

- Tempat botol

- Dukungan sepatu

- Tempat penyangga produk elektronik

Fitur Jalur Produksi Baki Telur

Kompatibel dengan Berbagai Bahan Baku

Dapat menggunakan bahan limbah umum seperti kertas bekas, kardus, dan koran secara langsung—mudah didapat dan hemat biaya.

Beragam Produk Akhir

Mampu memproduksi tidak hanya nampan telur, tetapi juga nampan buah, nampan telur bebek, tempat gelas, nampan botol, dan penyisip kemasan elektronik—satu lini, banyak kegunaan.

Opsi Output yang Fleksibel

Tersedia dalam berbagai model dengan kapasitas produksi berkisar antara 1.000 hingga 8.000 potong per jam, cocok untuk berbagai skala produksi.

Dapat Disesuaikan dengan Kebutuhan Anda

Cetakan, konfigurasi peralatan, dan tata letak semuanya dapat disesuaikan untuk mencocokkan produk dan kondisi pabrik tertentu.

Pengembalian Investasi yang Cepat

Peralatan yang tahan lama dan dapat diandalkan, dengan permintaan pasar yang tinggi untuk produk akhir, membantu pelanggan memulihkan investasi mereka dengan cepat.

Instalasi & Dukungan Purna Jual

Dilengkapi dengan panduan instalasi yang detail dan layanan purna jual yang kuat untuk memastikan produksi yang lancar dan kinerja yang stabil.

Proses Produksi Tray Telur

1, Tahap Pulping – Tangki Pencampuran Pulp

Kertas bekas dimasukkan ke dalam hydrapulper, di mana ia dipecah menjadi pulp dengan bantuan air. Pulp kemudian masuk ke tangki pencampuran, di mana konsentrasi disesuaikan dan dijaga tetap seragam melalui sistem pengadukan.

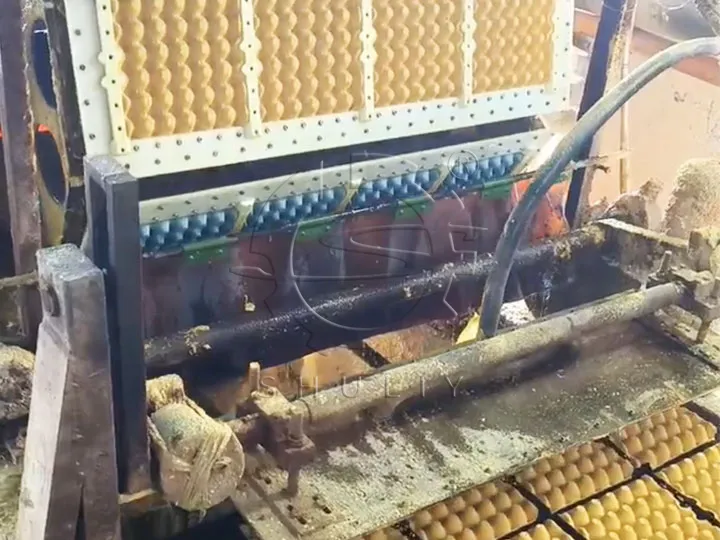

2, Tahap Pembentukan – Mesin Pembentuk Tray Telur

Pulp yang telah disiapkan dikirim ke mesin pembentuk tray telur, di mana ia dibentuk menjadi produk cetakan basah seperti tray telur atau tempat cangkir menggunakan sistem penyedotan vakum dan cetakan pembentuk.

3, Proses Pengeringan – Tiga Cara

Setelah pembentukan, produk pulp basah masuk ke tahap pengeringan untuk menghilangkan kelembapan dan meningkatkan kekuatan. Ada tiga metode pengeringan yang umum, dan pelanggan dapat memilih berdasarkan kebutuhan spesifik mereka:

- Pengering Logam Multi-Lapis

- Ruang Pengering Bata

- Pengeringan Alami dengan Sinar Matahari

Kami dapat merekomendasikan solusi terbaik berdasarkan kondisi lokasi dan anggaran Anda.

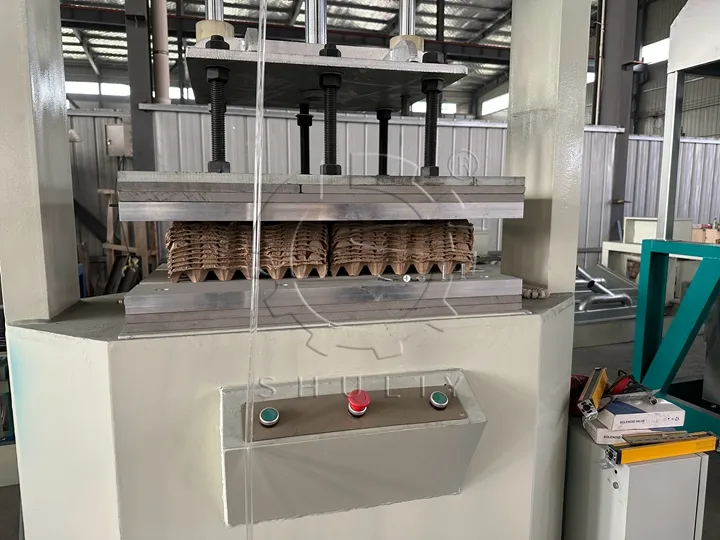

4, Penekanan Panas (Opsional) – Mesin Penekan Panas

Untuk produk berkualitas lebih tinggi seperti sisipan kemasan industri atau tray premium, proses penekanan panas tambahan dapat ditambahkan untuk membuat produk lebih halus, lebih tahan lama, dan terlihat lebih baik.

5, Penumpukan Produk Jadi (Opsional)

Setelah pengeringan, produk jadi dapat ditumpuk secara otomatis menggunakan sistem penumpuk, mengurangi tenaga kerja dan meningkatkan efisiensi pengemasan.

Parameter Teknis Pabrik Pembuatan Tray Telur

| Barang | Deskripsi Spesifikasi |

| Jenis Bahan Baku | Koran bekas, kardus, kertas buku, papan kertas, potongan tepi. |

| Jenis Produk Akhir | Tempat telur, tempat buah, pemegang cangkir, tempat botol, sisipan sepatu, kemasan dalam elektronik, dll. |

| Kapasitas Produksi | 1.000–8.000 pcs/jam (opsional) |

| Jumlah Cetakan | Cetakan tunggal / Cetakan ganda / Multi-cetakan (berdasarkan konfigurasi) |

| Bahan Cetakan | Paduan aluminium / Cetakan tembaga / Baja tahan karat (dapat disesuaikan) |

| Metode Pembentukan | Pembentukan dengan hisap vakum |

| Metode Pengeringan | Jalur pengeringan logam / Ruang pengeringan bata / Pengeringan sinar matahari alami (opsional) |

| Mode Operasi | Sepenuhnya otomatis |

| Kebutuhan Tenaga Kerja | 3–5 pekerja |

| Peralatan Opsional | Mesin press panas, stacker, mesin kemasan, dll. |

Di atas adalah spesifikasi dari lini produksi baki telur, jika Anda memerlukan parameter kustom lebih lanjut (seperti gambar cetakan, tata letak lini produksi, dll.), kami dapat memberikan solusi desain individu sesuai dengan ukuran pabrik pelanggan dan kebutuhan produk jadi.

Apa yang Bisa Kami Tawarkan

- Solusi produksi tray telur lengkap dari bahan baku hingga produk akhir

- Gambar tata letak dan skema listrik

- Dukungan instalasi di lokasi atau jarak jauh dan pelatihan operator

- Kustomisasi cetakan untuk ukuran dan desain tray yang berbeda

- Layanan purna jual cepat dan pasokan suku cadang

Hubungi Kami untuk Proposal yang Disesuaikan

Kami menawarkan solusi lini produksi baki telur yang disesuaikan dengan volume produksi, tata letak fasilitas, dan anggaran Anda. Silakan hubungi kami melalui email, telepon, atau situs web kami untuk menerima penawaran yang disesuaikan dan dokumentasi teknis. Kami siap mendukung proyek kemasan cetakan pulp Anda dengan peralatan dan layanan yang andal.