Metal crusher is designed for efficient crushing of a wide range of scrap metal materials and can be used as a standalone machine or integrated into a complete metal crushing and sorting line. It is widely applied in scrap metal recycling plants, metal processing centers, steel mill auxiliary facilities, and metal recovery enterprises.

What Is a Metal Crusher Machine

Our aluminum crusher is a hammer-type crushing machine used to reduce scrap metal into small particles or granules through high-speed impact. By using wear-resistant hammers and liners, the machine achieves stable crushing performance for both thin and relatively thick metal materials, while maintaining a consistent discharge size suitable for subsequent sorting or recycling processes.

Wide Range of Applicable Metal Materials

This machine is capable of crushing more than 200 types of metal materials, including but not limited to:

- Flattened vehicle bodies and dismantled car body components

- Light and thin materials that have been sheared or baled, with a density not exceeding 1 t/m³

- Household appliances such as used washing machines, refrigerators, air conditioners, and color steel sheets

- Scrap motorcycle, electric vehicle, and bicycle body parts

- Waste aluminum cans, paint buckets, and scrap aluminum

- Scrap iron sheets, waste steel, scrap iron, mixed scrap metal, broken bridge aluminum doors and windows, and radiators

Both thin materials (such as aluminum cans) and thicker metal components can be processed efficiently. Thin materials are typically crushed into small spherical shapes, while thicker materials are discharged as flakes or small blocks.

Technical Advantages of Our Metal Scrap Crusher

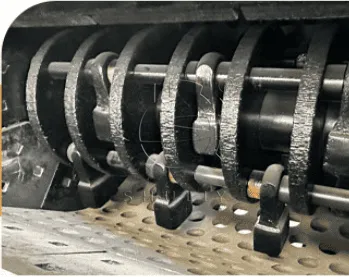

Wear-Resistant Hammers and Screen Plates

The hammer heads and screen plates are cast from alloy steel, providing excellent wear resistance, long service life, and high crushing efficiency.

The hammer thickness and number of hammer claws can be adjusted or replaced according to different material types. When uncrushable materials enter the crushing chamber, the hammers can swing freely, allowing such materials to be discharged through a dedicated outlet. This design effectively reduces the risk of damage to the equipment.

Screens can be customized to control the size of the output material.

Heavy-Duty Rotor and High-Strength Bearings

The machine features a heavy-duty rotor design manufactured with strict machining processes. The rotor bearings are made of cast steel, significantly improving radial strength and ensuring stable operation under continuous high-load conditions.

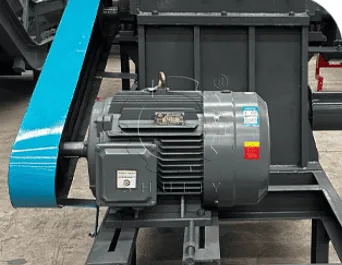

Full Copper-Core Motor

Equipped with a full copper-core motor, the crusher offers low energy consumption, stable power output, and a long service life.

Reinforced Wear-Resistant Machine Body

The machine body is constructed from extra-thick steel plates and processed with high-standard welding and polishing techniques, ensuring a robust structure, durability, and safe operation.

Multiple Safety Protection Systems

The metal crusher is equipped with motor overload protection and a power interlock system. A sealed feeding inlet design effectively prevents material from splashing during operation, enhancing overall safety.

Aluminum Crusher Technical Specifications

This series of metal crushers is available in multiple models, with processing capacities ranging from 600 kg/h to 18,000 kg/h, meeting the production requirements of scrap metal processing projects of different scales. Power rating, rotor speed, and structural configuration vary by model, making the machines suitable for continuous crushing of light metal materials as well as mixed scrap metal.

The standard discharge size ranges from 3–10 mm and can be customized according to the customer’s actual requirements for finished material size. Conveying systems can be installed at both the inlet and outlet to ensure stable and continuous material flow, allowing easy integration with downstream equipment such as magnetic separators, eddy current separators, and metal dry polishing machines.

Flexible Integration into a Metal Crushing and Sorting Line

This metal crusher can operate as a standalone machine or be combined with other equipment to form a complete aluminum scrap crushing and sorting line, such as:

- Metal shredder

- Eddy current separator

- Metal dry polishing machine

Conveyors can be installed at both the feeding and discharging ends of the machine to ensure smooth, continuous material flow throughout the entire production line.

Customized Metal Crusher Solution

As a professional supplier of scrap metal processing equipment, we offer a wide range of metal crushers. Based on your material type, feeding size, target discharge size, and required capacity, we can provide a tailored equipment selection and configuration.

Different models, power ratings, and configurations result in variations in processing capacity and equipment cost. According to your actual operating conditions, we can recommend the most suitable metal crusher model and integrate it with conveyors, metal shredders, eddy current separators, metal dry polishing machines, and other equipment to form an efficient and stable metal crushing and sorting line.

If you are planning a scrap metal recycling project, please feel free to contact us with details of your materials and capacity requirements. We will provide a complete equipment solution, detailed technical specifications, and a reference quotation based on your needs.