A linha de produção de blocos de gelo seco é uma solução de produção completa e contínua que fornecemos para clientes que necessitam de uma fabricação estável e eficiente de blocos de gelo seco. Desde a pelletização do gelo seco até à prensagem de blocos, seguida de transporte e embalagem, cada etapa da linha é projetada com fiabilidade, facilidade de operação e escalabilidade em mente. Como fornecedor, o nosso foco não está apenas no equipamento em si, mas na adequação desta linha de produção às suas necessidades de capacidade, cenários de aplicação e custos operacionais a longo prazo.

Por que escolher uma linha de produção completa de blocos de gelo seco?

Na nossa comunicação com os clientes, muitas vezes descobrimos que muitos utilizadores inicialmente consideram apenas uma única prensa de blocos de gelo seco. No entanto, na produção real, isto pode levar a problemas como má conexão do processo, custos laborais mais elevados e qualidade inconsistente do bloco.

Por esta razão, geralmente recomendamos uma linha de produção completa de blocos de gelo seco, que integra pelletização, formação de blocos, transporte e embalagem num sistema coordenado. Isto garante um fluxo de material suave, produção estável e melhor controlo geral da produção.

Vídeo de operação da fábrica de gelo seco

Pelletizador de gelo seco: fornecimento de matéria-prima estável para a linha de produção

O papel do processo de pelletização

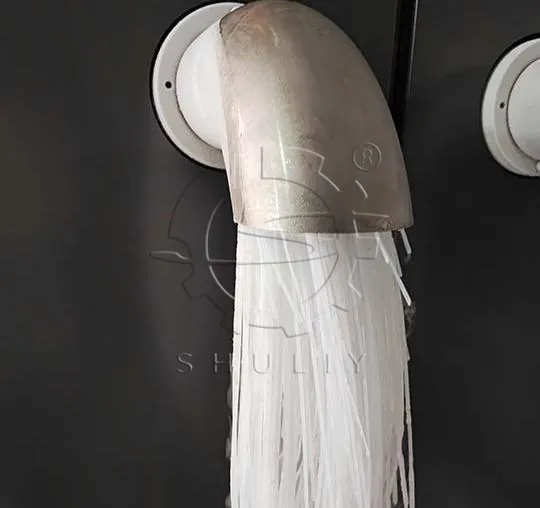

O primeiro passo da fábrica de gelo seco é o pelletizador de gelo seco, que converte CO₂ líquido em pellets de gelo seco uniformes. Este passo tem um impacto direto na densidade do bloco e na qualidade de formação no processo de prensagem subsequente.

Considerações-chave ao selecionar o Pelletizador

- Tamanho uniforme do pellet para uma formação de blocos consistente

- Produção contínua para corresponder à capacidade da prensa de blocos

- Estrutura selada para reduzir perdas por sublimação do gelo seco

Para clientes com diferentes requisitos de capacidade, ajudamos a selecionar o modelo adequado para evitar subdesempenho ou dimensionamento desnecessário.

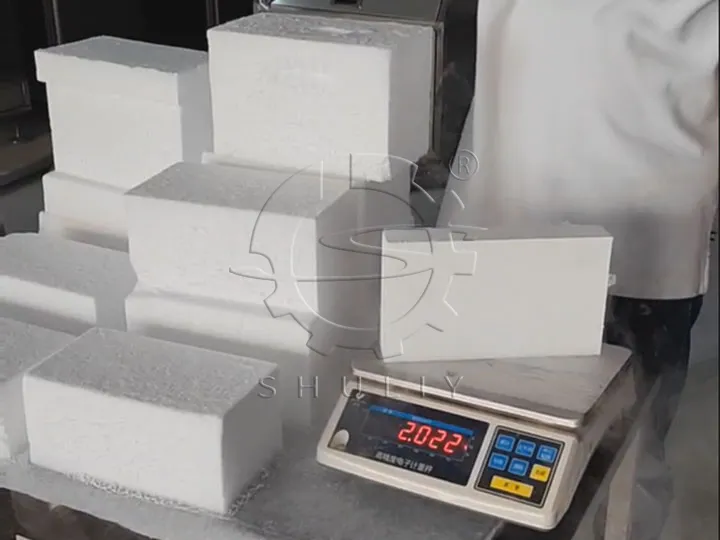

Prensa de blocos de gelo seco: comprimindo pellets em blocos sólidos de gelo seco

Processo de formação de blocos

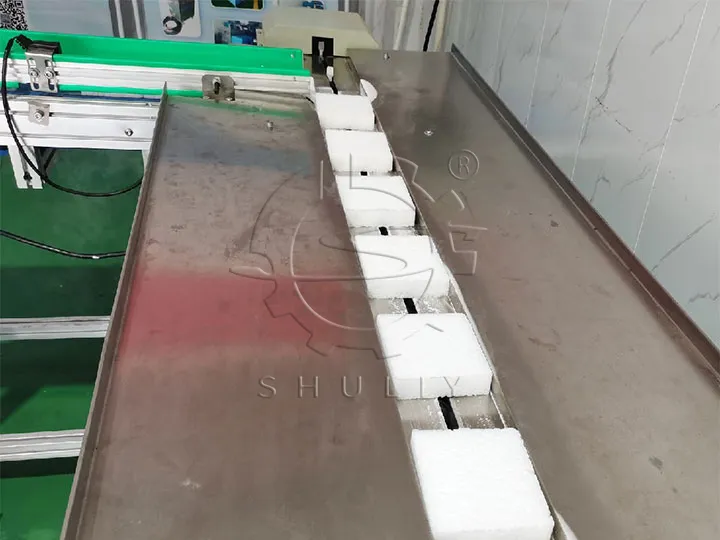

Os pellets de gelo seco são transportados para a prensa de blocos, onde são comprimidos sob alta pressão em blocos sólidos de gelo seco. O tamanho, a espessura e o peso do bloco podem ser ajustados de acordo com as suas necessidades específicas de aplicação.

Preocupações comuns dos clientes

- Consistência na densidade do bloco

- Facilidade de substituição do molde

- Flexibilidade para diferentes tamanhos de blocos

Ao projetar uma linha de produção de blocos de gelo seco, confirmamos as especificações do produto com antecedência para garantir uma operação estável a longo prazo da prensa de blocos.

Sistema de transporte: Ligando cada processo e reduzindo manuseio manual

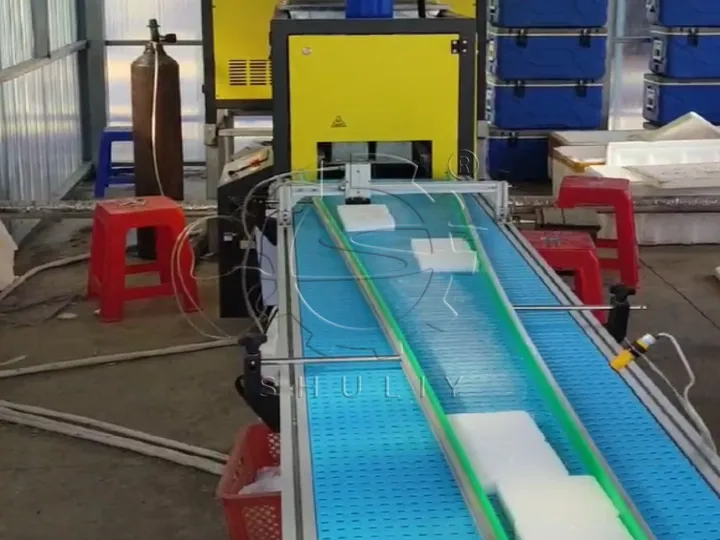

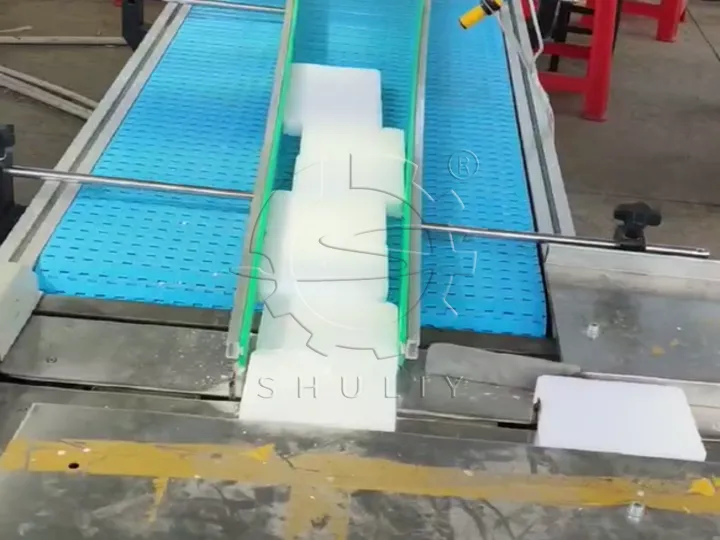

Após a formação do bloco, os blocos de gelo seco são transferidos para a próxima fase através de um sistema de transporte compatível com baixas temperaturas. Embora esta secção não molde diretamente o produto, desempenha um papel importante na eficiência geral da produção.

Vantagens do sistema de transporte

- Redução do manuseio manual e aumento da segurança

- Tempo de exposição mais curto, minimizando perdas por sublimação

- Conexão suave com o sistema de embalagem

Projetamos layouts de transportadores retos ou de curva com base no espaço do seu atelier e condições do local.

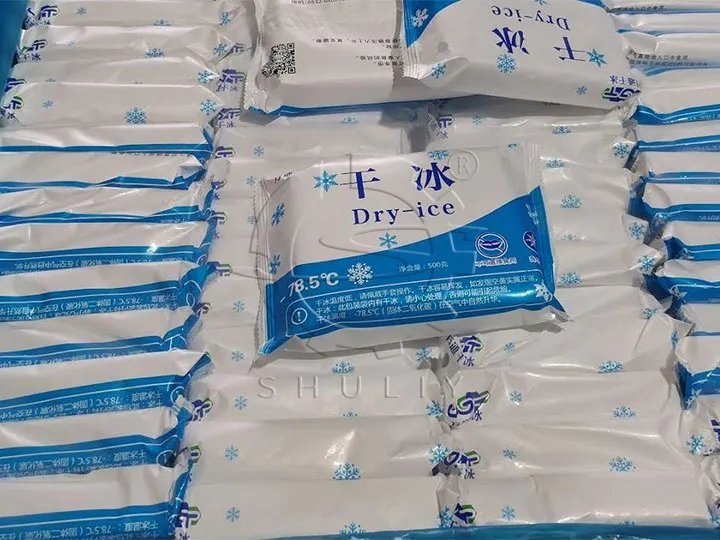

Sistema de Embalagem: Melhorando a eficiência de armazenamento e transporte

O papel da embalagem na linha de produção de blocos de gelo seco

Após a formação dos blocos de gelo seco, devem ser embalados o mais rapidamente possível para reduzir a sublimação. O sistema de embalagem pode ser configurado como semi-automático ou com assistência manual, dependendo das suas necessidades operacionais.

Campos de aplicação típicos

- Transporte de cadeia de frio para alimentos

- Armazenamento frigorífico farmacêutico

- Resfriamento e limpeza industrial

Ajudamos os clientes a selecionar soluções de embalagem adequadas com base nos seus cenários de aplicação específicos.

Vantagens gerais da linha de produção de blocos de gelo seco

Do ponto de vista de um fornecedor de máquinas de gelo seco, uma linha de produção de blocos de gelo seco bem projetada deve oferecer:

- Fluxo de processo claro com equipamento bem ajustado

- Capacidade escalável para diferentes tamanhos de projeto

- Operação simples e manutenção fácil

- Componentes principais projetados para uso a baixas temperaturas e a longo prazo

Estes também são os pontos principais que focamos ao configurar linhas de produção para os nossos clientes.

Para quem é adequada esta planta de fabricação de gelo seco?

A linha de produção de blocos de gelo seco é especialmente adequada se você:

- Planeamento para produção contínua e a longo prazo de blocos de gelo seco

- Requerer tamanho e densidade de bloco consistentes

- Quer reduzir a entrada de mão-de-obra e melhorar a eficiência

- Estão a preparar-se para expandir a capacidade ou entrar em novos mercados de aplicação

Fale connosco para uma linha de produção de blocos de gelo seco adaptada às suas necessidades

Cada cliente tem objetivos de produção, condições de espaço e considerações orçamentais diferentes. Em vez de oferecer um modelo fixo, focamos em fornecer uma linha de produção de blocos de gelo seco que corresponda às suas necessidades reais.

Contacte-nos hoje para discutir a sua capacidade alvo, especificações do bloco de gelo seco e áreas de aplicação. Ajudaremos a construir uma solução prática e fiável de produção de blocos de gelo seco.