Haben Sie Schwierigkeiten mit Rohstoffen, die zu lang für die direkte Verarbeitung in Ihrer Textilrecycling- oder Faseraufbereitungsanlage sind? Unsere Faser-Schneidemaschine ist speziell dafür ausgelegt, Abfallstoffe, Vliesstoffe und lange synthetische Fasern in kurze, einheitliche Stücke zu schneiden – ideal für die Vorverarbeitung vor dem Öffnen, Kardieren oder Pelletieren. Sie spielt eine entscheidende Rolle bei der Verbesserung der Effizienz und der Qualität des Endprodukts in verschiedenen Recyclingbranchen.

Wir bieten fünf verschiedene Modelle von Faser-Schneidemaschinen an, mit einer Ausstoßkapazität von 300 kg/h bis 5000 kg/h. Die Schnittlänge ist zwischen 5 mm und 300 mm einstellbar, um verschiedenen Produktionsbedürfnissen gerecht zu werden, während die Schnittdicke von 20 mm bis 200 mm reicht, was sie für die Verarbeitung einer Vielzahl von Materialien geeignet macht.

Was ist eine Textilschneidemaschine?

Eine Faser-Schneidemaschine ist ein industrielles Gerät, das verwendet wird, um lange Streifen oder sperrigen Textilabfall in kurze, handhabbare Fasersegmente zu schneiden. Diese Maschine wird häufig vor dem Faseröffnen eingesetzt und ist unerlässlich in Prozessen wie der Produktion von recycelter Baumwolle, der Herstellung von Filz, der Füllung von Spielzeugen, akustischen Materialien für die Automobilindustrie und der Produktion von Isolierung.

Sie wird oft mit Faseröffnern, Förderbändern oder Ballenpressen kombiniert, um eine komplette Recyclinglinie zu bilden.

Arbeitsvideo der Waste Cloth Cutting Machine

Anwendbare Rohstoffe

Unsere Stoffabfall-Schneidemaschine eignet sich zur Verarbeitung einer Vielzahl von weichen oder flexiblen Materialien, einschließlich:

- Abfallkleidung und textile Zuschnitte

- Denimreste, Baumwollstoffe, Mischgewebe

- Lange synthetische Fasern, Polyester, Vliesstoff

- Kokosfasern, Jute, Flachs und Sisalfasern

- Riemen, industrielle Filterstoffe, Garnkugeln

Hauptmerkmale und Vorteile der Faser-Schneidemaschine

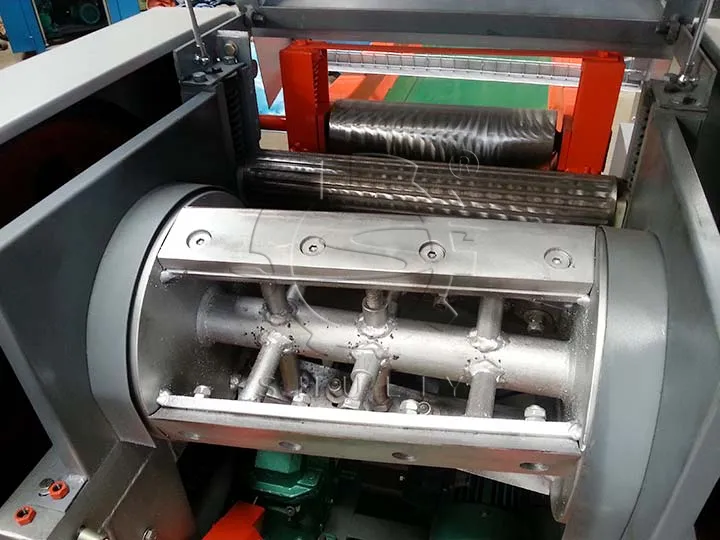

- Effizientes Schneidsystem – Ausgestattet mit hochfesten Legierungs-Klingen für schnelles, gleichmäßiges Schneiden mit langer Lebensdauer

- Einstellbare Schnittlänge – Die Schnittgröße kann gemäß den Anforderungen der nachgelagerten Verarbeitung eingestellt werden

- Kompaktes Design – Platzsparend, ideal für kleine und mittelgroße Recyclinganlagen

- Stabil und wartungsarm – Mit Bandzufuhr und elektrischer Steuerung, einfach zu bedienen und zu warten

- Einfache Integration – Kann in Verbindung mit Faseröffnungsmaschinen, Ballenpressen usw. verwendet werden

Einige Details zur Abfallstoffschneidemaschine

- Kapazität: 300-5000kg/h

- Klingenmaterial: Werkzeugstahl

- Schnittlänge: 5mm-300mm

- Schnittdicke: 20mm-200mm

- Muss alle drei Monate geschärft werden

- Wenn das Material zu klein ist, z. B. 1-2 cm, müssen Sie ein Blasgerät am Ausgang hinzufügen.

Parameter einiger Modelle von Textilschneidemaschinen

| Modell | Kapazität | Leistung | Schnittgröße | Schnittdicke | Abmessungen |

| SL-800 | 500-800kg/h | 7,5+1,5kw | 5—150mm | 30-80mm | 3200*1000*1200mm |

| SL-1200 | 800-1200kg/h | 15+2,2 kW | 5—150mm | 30-80mm | 7000*1500*1500 mm |

| SL-1600 | 1000-3000 kg/h | 18+3 kW | 5–300mm | 30–150mm | 7000*1800*1950 mm |

Häufig gestellte Fragen

F1: Kann die Schnittlänge angepasst werden?

A: Ja, die Schnittgröße kann durch Anpassung der Zuführgeschwindigkeit und der Klingenrotation gesteuert werden.

Q2: Kann ich verschiedene Klingenmaterialien wählen?

A: Absolut. Wir bieten verschiedene Klingenoptionen wie 45# Stahl und Legierungsstahl an, um den Haltbarkeitsanforderungen gerecht zu werden.

Q3: Ist die Faser-Schneidemaschine einfach zu bedienen?

A:Ja. 1-2 Personen können den Stoffschneider für die Recycling von Stoffresten bedienen.

Erhalten Sie Ihre maßgeschneiderte Lösung & Angebot

Suchen Sie eine langlebige und effiziente Faser-Schneidemaschine? Kontaktieren Sie uns jetzt für maßgeschneiderte Empfehlungen.

Wir helfen Ihnen, das richtige Modell basierend auf Ihren Materialien, der erforderlichen Kapazität und dem Standortlayout auszuwählen.