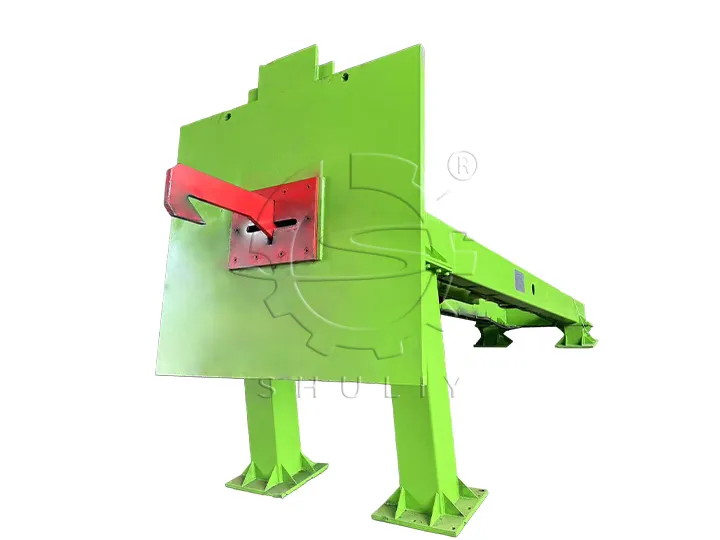

OTR debeader ni mashine yenye nguvu na maalum iliyoundwa kutoa nyuzi nzito na ngumu za chuma kutoka sehemu ya bead ya matairi makubwa ya OTR (off-the-road). Ni hatua muhimu ya kwanza katika urekebishaji wa matairi ya OTR, ikisaidia kutenganisha chuma chenye thamani kutoka kwa mpira huku ikipunguza kuvaa na tear kwenye mashine zinazofuata.

Maombi na Kazi

Hii vifaa vinafaa kwa matairi makubwa kutoka kwa malori ya madini, magari ya uhandisi, na magari ya usafirishaji mazito. Matairi haya yana nyuzi za chuma zenye nguvu ambazo zinahitaji kuondolewa kabla ya kusagwa au kupunguzwa kwa ukubwa zaidi.

Hii OTR debeader imeundwa kutoa bead nzima ya chuma kwa mara moja, ikiacha muundo wa tairi kuwa salama kwa hatua inayofuata ya urejeleaji.

Kanuni ya Kazi ya Mashine ya OTR Debeader

- Opereta anaweka tairi la OTR kwenye mfumo wa hook.

- Mfumo wa hydraulic unadhibiti hook ya chuma kushika tairi kwa nguvu.

- Mara baada ya kuimarishwa, mfumo wa kuvuta unawashwa.

- Mashine inatoa nguvu kubwa ya hydraulic kutoa pete ya waya ya chuma kutoka eneo la bead ya tairi.

- Waya ya chuma iliyotengwa inaweza kukusanywa kwa ajili ya urejeleaji, na tairi inaendelea kwa ajili ya usindikaji zaidi.

Video ya Kazi ya Mashine ya Kuchora Waya ya Tairi la OTR

Vigezo vya kiufundi

| Kipengee | Vipimo |

| Urefu wa mashine | Meta 4 |

| Nguvu | 22+3kw |

| Vikt | 9500kg |

| Kushughulikia ukubwa wa tairi | 1800-4000mm |

| Uwezo wa uzalishaji | Dakika 2 kwa wakati |

Wasiliana nasi kwa Suluhisho Kamili

Tunatoa suluhisho zilizobinafsishwa kwa mistari ya kuchakata matairi ya OTR, pamoja na debeaders, dismantlers, shredders, separators za chuma, na mashine ya kusaga mpira.

Wasiliana nasi sasa kwa vipimo, bei, na miundo ya mpangilio iliyoundwa kwa ajili ya mradi wako.