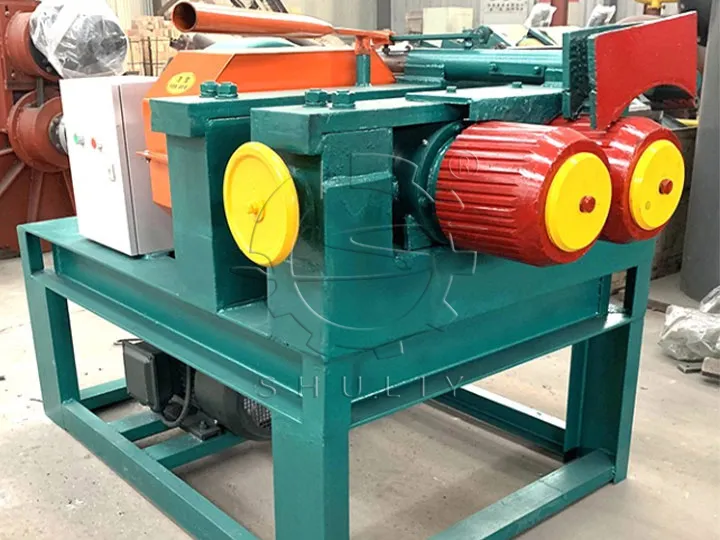

The tire steel wire separator is a machine designed to separate steel wire beads from scrap tyres, for bead sections up to 1200 mm in diameter. It is usually used in conjunction with a tire sidewall cutting machine to separate the steel wire from the rubber of the cut bead section, and is an indispensable part of the waste tyre recycling line.

Jukumu la mashine ya kuondoa waya wa tairi

Hii vifaa vinatumia shinikizo kubwa kwa kutumia rollers mbili zinazozunguka na kubana ili kutenganisha kwa ufanisi waya wa chuma uliowekwa ndani ya bead ya tairi. Waya wa chuma uliotenganishwa unaweza kurejelewa kama chuma kilichorejelewa, wakati sehemu ya goma inaweza kutumwa kwa shredder ya tairi kwa ajili ya usindikaji zaidi, ikiongeza kiwango cha matumizi ya rasilimali kwa ujumla.

Vipengele na faida

- Ufanisi mkubwa wa kujitenga: Nguvu kali ya extrusion inahakikisha utenganisho kamili na safi wa waya za chuma

- Kubadilika kwa upana: Pengo la roller linaloweza kurekebishwa ili kuendana na unene kadhaa wa bead

- Ubunifu wa kudumu: Ukiwa na vifaa vya kuvaa sugu kwa maisha marefu ya huduma

- Muundo wa Compact: Rahisi kufanya kazi na kuokoa nafasi

- Mifano inayoweza kufikiwa: Inapatikana katika mifano tofauti kushughulikia ukubwa mkubwa wa tairi kama inahitajika

Kanuni ya kufanya kazi ya tairi ya waya ya chuma

Mgawanyiko wa waya wa chuma wa tairi una rollers mbili zenye nguvu ya juu. Wakati wa kufanya kazi, bead ya tairi hulishwa kwa mikono kati ya rollers. Mara mashine inapoanza, rollers huzunguka katika maingiliano, kutumia compression kali kwa bead. Shinikiza hutenganisha waya wa chuma kutoka kwa mpira.

Matumizi ya mgawanyaji wa waya wa chuma

- Vituo vya kuchakata taka taka

- Mimea iliyorejeshwa ya uzalishaji wa mpira

- Taka taka ya kuchakata tairi

Vigezo vya kiufundi

- Kipenyo kinachofaa cha tairi: ≤1200mm

- Vifaa vya roller: Chuma ngumu

- Pengo la roller linaloweza kurekebishwa: Inaweza kubadilishwa kwa msingi wa unene wa bead

- Nguvu ya gari: Imesanidiwa kulingana na mfano

- Uwezo wa usindikaji: 120pcs/h (kwa kumbukumbu)