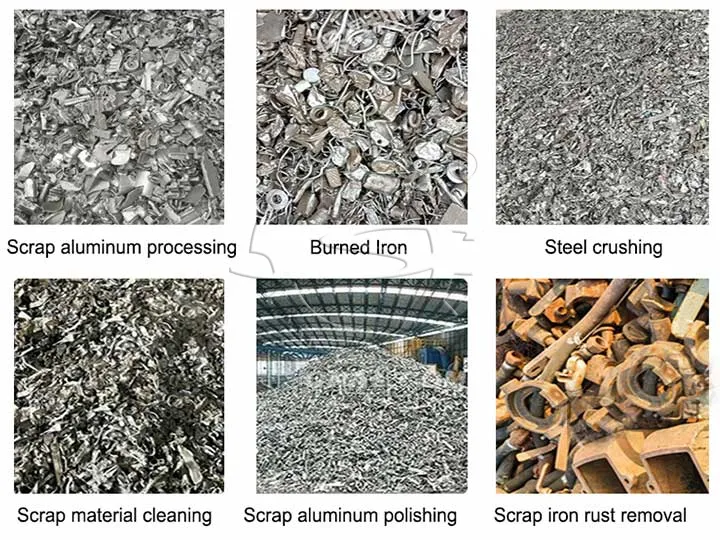

In discussions with customers about metal surface finishing solutions, the scrap metal polishing machine is one of the machines most frequently mentioned. Many customers are not dealing with uniform or standard parts, but rather with burnt iron scrap, crushed materials, scrap aluminum, stainless steel parts, oily and rusty mixed materials.

It is under these practical conditions that the drum-type dry metal grinding and polishing machine proves to be a stable and effective solution for continuous operation.

As an equipment supplier, our focus is not just on machine specifications, but on whether this solution truly matches your material characteristics and processing goals.

Application Scope: Designed for Various Metals and Mixed Scrap Materials

Based on real project experience, this rotary drum polishing machine is mainly used for processing:

- Metal and burnt iron scrap

- Stainless steel parts

- Scrap aluminum, scrap steel, and other non-ferrous metals

- Oily and rusty metal fragments

- Certain non-metallic product parts

The main processing purposes include:

- Deburring

- Rust and oil removal

- Edge rounding

- Surface finishing and bright polishing

For easily deformable workpieces, this scrap metal polishing machine offers a clear advantage. After processing, the parts can maintain their original dimensional accuracy, while surface roughness can be improved by 1–2 grades, which is one of the key reasons customers choose drum-type dry grinding equipment.

This model is especially suitable for medium to large-sized parts requiring surface finishing.

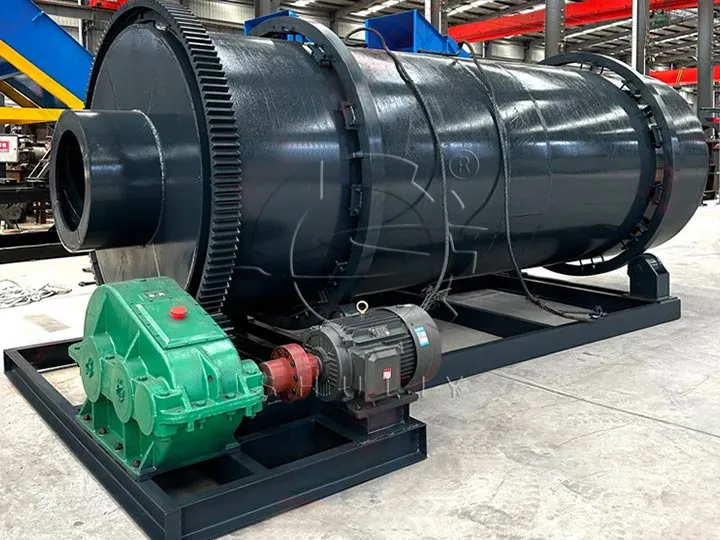

Working Principle: Dry Polishing Through Continuous Tumbling Inside the Drum

During equipment selection, customers often ask how the machine actually works.

This scrap aluminum polishing machine is suitable for metal and scrap aluminum materials with a diameter of less than 400 mm, especially materials with oil and rust on the surface.

The working process is straightforward and reliable:

- An electric motor drives the reducer to rotate the drum

- The drum is equipped with guide liners and turbulence liners

- Materials and grinding media are fed into the drum via a conveyor

- As the drum rotates, materials and media are continuously

- thrown, tumbled, rubbed, and stirred

During this process, the grinding media fully absorb oil stains and rust from the material surface, achieving dry degreasing, rust removal, and polishing without water.

This dry processing method is particularly suitable for applications where wet treatment is not preferred.

Key Structural Features: Built for Stability and Long-Term Operation

From delivery and after-sales experience, we find that customers are most concerned about long-term stability and durability, especially under continuous operation conditions.

High-Strength Ring Gear Structure

- Made of high-strength alloy

- One-piece casting design

- Stable transmission and reliable operation

This structure helps ensure smooth operation and reduces mechanical risks during long-term use.

Wear-Resistant Machine Body

- Manufactured with extra-thick steel plates

- High-standard welding and surface finishing

- Durable structure suitable for heavy-duty materials

This design is particularly important when processing burnt iron, crushed scrap, and scrap steel with high abrasion.

Enlarged Hopper for Uniform Feeding

- Enlarged feeding hopper

- More even material feeding

- Helps avoid unstable output

Uniform feeding plays an important role in achieving consistent polishing results and stable processing capacity.

Integrated Aluminum Thermal Break Recycling Line

In many projects, the scrap metal polishing machine is used as a key unit within an aluminum thermal break crushing and separation line rather than as a standalone machine. It can be combined with metal shredders, crushers, eddy current separators, and dry grinding equipment to form a continuous processing line.

In this system, metal shredding machine and metal crusher handle size reduction, the eddy current separator separates metal from non-metal materials, and the drum polishing machine performs oil removal, rust removal, and surface finishing. This integrated solution improves recycling efficiency and meets factory requirements for stable and automated operation, with line configuration tailored to actual material and capacity needs.

Is This Scrap Metal Polishing Machine Right for Your Application?

If your materials include:

- Metal or burnt iron scrap

- Scrap aluminum, scrap steel, or stainless steel parts

- Oily, rusty, and irregularly shaped materials

- Parts that require surface finishing without dimensional deformation

Then the scrap metal polishing machine is often a practical and reliable option to consider.

If you are planning a metal surface finishing project or an aluminum thermal break recycling line and want to confirm whether this solution matches your material and capacity requirements, feel free to contact us for further discussion.

By sharing your material type, processing volume, and application needs, we can help you evaluate the suitable equipment configuration and provide relevant technical details and project references. We look forward to supporting you with a practical and reliable solution tailored to your actual production conditions.