Гантри-ножницы для металлолома — незаменимое оборудование на современных предприятиях по переработке металла. Они предназначены для резки и обработки громоздкого металлического лома в более мелкие, однородные куски, что облегчает хранение, транспортировку и дальнейшую переработку, такую как плавка или выплавка. Эта машина широко используется на свалках металлолома, сталелитейных заводах и в центрах переработки, где обрабатывают стальные листы, балки I-образного и H-образного сечения, кузова автомобилей, арматуру, трубы и легкие металлические профили.

Для клиентов, стремящихся повысить производительность и сократить ручной труд, гантри-ножницы предлагают автоматизированное и надежное решение.

Что такое гантри-ножницы и как они работают?

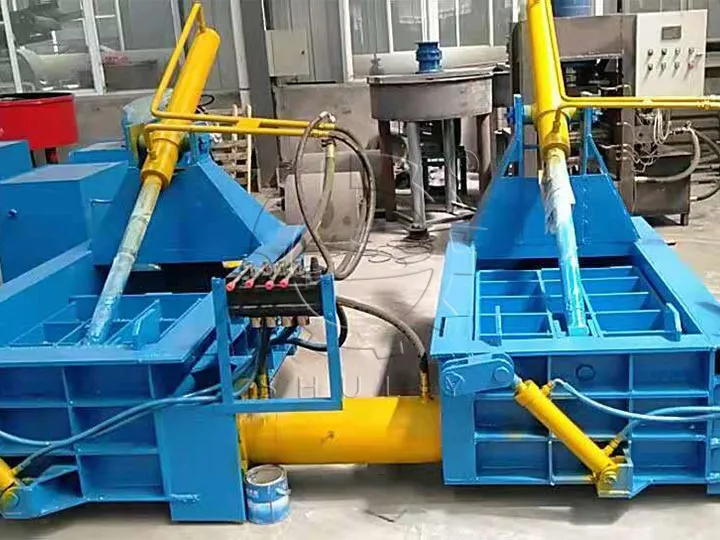

Гантри-ножницы для металлолома, также известные как гидравлическая гантри-ножницы для металлолома, — это мощное оборудование, предназначенное для резки больших объемов металлического лома на более мелкие, более удобные и более плотные куски.

Операционный процесс является образцом эффективности и автоматизации:

- ЗагрузкаЛом металла загружается в длинный просторный бокс для подачи материала с помощью крана-манипулятора или другого оборудования для загрузки.

- УплотнениеГидравлический прессующий цилиндр или зажимная крышка сжимают загруженный лом сбоку или сверху, уплотняя свободный материал для обеспечения чистого и эффективного реза.

- КормлениеАвтоматический механизм подачи — либо прочный двухцепочечный толкатель, либо мощный гидравлический цилиндр — подталкивает уплотненный лом к режущим лезвиям.

- РезкаАктивируются основные цилиндры резки, приводя верхний нож вниз с огромной силой (от 630 до более 2000 тонн), чтобы прорезать металл.

- Повторение циклаСистема автоматически повторяет цикл подачи и резки, непрерывно обрабатывая материал в ящике, пока он не опустеет. Весь процесс может безопасно управляться одним оператором через панель управления ПЛК или беспроводное дистанционное управление.

Видео работы гантри-ножниц для металлолома

Ключевые области применения: где необходимы гидравлические гантри-ножницы?

Универсальность и огромная мощность гантри-ножниц для металлолома делают их ключевым оборудованием в различных отраслях промышленности. Их способность обрабатывать широкий спектр материалов делает их выгодным вложением для:

- Центры переработки металлоломаДля обработки смешанного тяжелого лома, И-образных балок, H-образных балок, арматуры, стальных пластин и транспортных средств на конце срока службы (ELV).

- Стальные заводы и литейные цехаДля измельчения закупленного лома или внутреннего производственного лома до размеров, пригодных для плавки, повышая эффективность плавления и удобство обработки.

- Объекты демонтажа автомобилейИдеально подходит для резки сжатых кузовов и рам автомобилей, упрощая процесс разделения и переработки материала.

- Магазины крупномасштабной металлообработкиДля управления и переработки больших отрезков и скелетных пластин из производственных процессов.

- Проекты демонтажаДля обработки конструкционной стали и другого крупного металлического мусора прямо на месте или на перерабатывающем предприятии.

Преимущества выбора гидравлических гантри-ножниц Shuliy

Сила резки для тяжелых материалов

С ассортиментом моделей с номинальной силой резки от 630 до 2000 тонн (а также доступными большими кастомными моделями) наши гантри-ножницы для металлолома без усилий режут самый жесткий лом. Эта мощь обеспечивает возможность переработки более широкого спектра материалов, увеличивая масштаб и прибыльность операций.

Прочная конструкция и высокая долговечность

- Головки резака из литой сталиВысокая стойкость к огромному давлению и износу, обеспечивая долгий срок службы.

- Передовой дизайн слайдовНаши более крупные модели оснащены трехсторонним слайд-дизайном для дорожки резака, инкрустированным бронзой и износостойкими пластинами из сплава 55SiCr. Это снижает трение, обеспечивает более плавную работу и значительно увеличивает срок службы машины.

- Автоматическая система смазкиАвтоматический насос точно смазывает направляющие, минимизируя износ и снижая требования к техническому обслуживанию.

Высокая эффективность и автоматизация работы

- ПЛК управление и дистанционный пускПередовая система ПЛК позволяет полностью автоматические или полуавтоматические циклы. Включенное беспроводное дистанционное управление повышает безопасность оператора, позволяя управлять машиной на безопасном расстоянии, вдали от зоны резки.

- Оптимизированное время циклаС частотой резки 3-5 раз в минуту наши машины обеспечивают высокую пропускную способность, позволяя перерабатывать больше тонн в час.

- Эффективные системы подачиМы предлагаем как двухцепочечное подающее устройство с толкателем для стандартных применений, так и гидравлический цилиндр для наших самых мощных моделей, обеспечивая стабильную и надежную подачу материала.

Универсальные модели для вашего масштаба операций

Мы понимаем, что каждая операция уникальна. Наши гантри-ножницы для металлолома доступны в различных размерах и конфигурациях, чтобы идеально соответствовать вашим потребностям — от средних площадок до крупнейших сталелитейных заводов. Независимо от того, нужен ли вам компактный бункер подачи длиной 6 метров или массивный 8-метровый бункер с более широким резовым проемом, у нас есть подходящая модель.

Наши модели гантри-ножниц: технический обзор

Чтобы помочь вам выбрать подходящие портальные ножницы для металлолома, вот сравнительная сводка наших популярных моделей. Обратите внимание, что спецификации могут быть настроены.

| Характеристика | Модель-630 | Модель-800 | Модель-1500(цепная подача) | Модель-2000(цилиндровая подача) |

| Максимальная сила резки | 630 тонн | 800 тонн | 1500 тонн | 2000 тонн |

| Размер бункера для материала (ДШВ) | 6000*1500*800 мм | 8000*1800*1200 мм | 8000*2400*1000 мм | 8000*2100*900 мм |

| Ширина реза | 1600 мм | 1800 мм | 2500 мм | ≤ 2200 мм |

| Суммарная мощность двигателя | 130 КВт | 180 КВт | 290,7 КВт | 425 КВт |

| Метод подачи | Двойная цепная подача | Двойная цепная подача | Гидравлический цилиндр для проталкивания | Гидравлический цилиндр для проталкивания |

| Система охлаждения | Принудительная воздушная система охлаждения | Принудительная воздушная система охлаждения | Система водооборотного охлаждения | Принудительное водяное охлаждение |

| Система управления | ПЛК + дистанционное управление | ПЛК + дистанционное управление | ПЛК + дистанционное управление | ПЛК + дистанционное управление |

Это краткое изложение ключевых спецификаций. Для полного технического паспорта свяжитесь с нами.

Другое оборудование для переработки металла

В операциях по переработке металлов, помимо использования портальных ножниц для резки металлолома, многие клиенты также выбирают другое оборудование для дальнейшего повышения эффективности обработки.

- Для крупного и рыхлого металлолома сначала можно использовать металлоломный шредер, чтобы раздробить его на меньшие куски, что облегчает сортировку и переплавку.

- Если целью является уменьшение объема лома для облегчения хранения и транспортировки, то пресс для металлолома могут сжимать лом стали, алюминия, меди и других металлов в плотные тюки, снижая логистические расходы.

Эти машины работают автономно и могут быть приобретены отдельно в зависимости от конкретных потребностей, помогая клиентам более эффективно обрабатывать различные виды металлолома.

Почему стоит сотрудничать с Shuliy Machinery?

- Экспертные консультации: мы работаем с вами, чтобы понять ваши потребности в переработке и рекомендовать идеальную конфигурацию машины.

- Качественное производство: мы соблюдаем строгие стандарты контроля качества, чтобы поставлять оборудование, которое надежно, эффективно и рассчитано на работу в самых суровых промышленных условиях.

- Глобальная поддержка: мы предлагаем комплексное послепродажное обслуживание, включая установку, обучение и наличие запасных частей, чтобы обеспечить работу вашего оборудования на максимальной мощности.