蛋托生产机器是纸浆成型生产线的核心组件。它通过真空吸附到模具上将纸浆成型为蛋托、水果托、杯架等产品。该机器操作简单,自动化程度高,适合各种规模的工厂。它广泛应用于食品包装、农业、工业缓冲等领域。

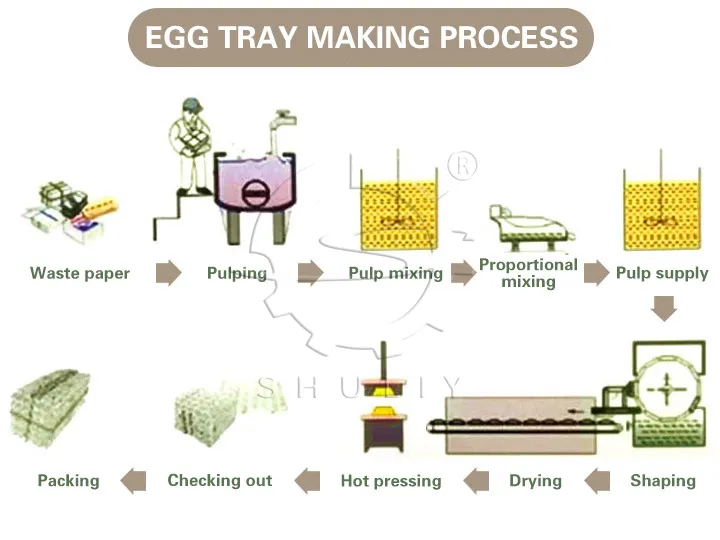

工作原理与生产过程

蛋托生产机器使用真空成型原理:

浆料通过供料泵输送到成型模具。通过真空吸力,浆料均匀附着在模具表面,形成湿托盘。湿托盘随后通过转移模具转移到干燥区。此过程是自动化且高效的。

生产流程:

废纸浆化 → 纸浆过滤与混合 → 成型 → 脱水与转移 → 干燥 → 成品堆放

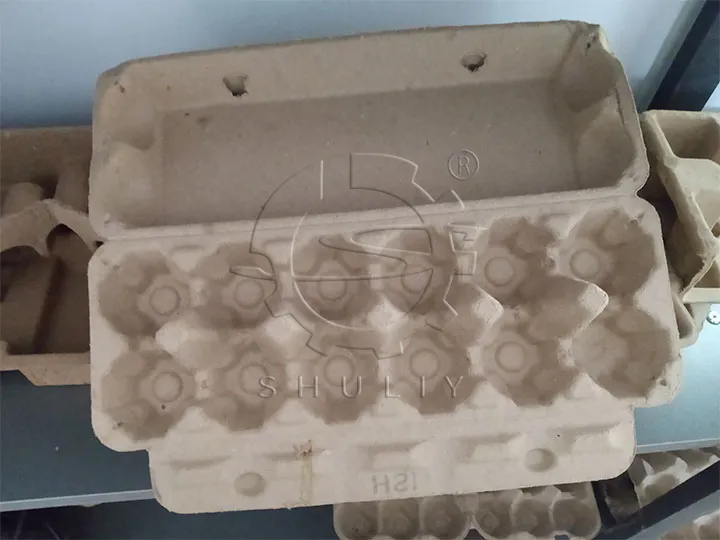

产品应用与模具灵活性

蛋托机可以通过简单更换模具生产多种成型纸浆产品,包括但不限于:

- 蛋托(鸡蛋、鸭蛋等)

- 杯架,水果托盘,瓶托盘

- 鞋垫,电子包装托盘

- 工业缓冲托盘,医疗包装

模具定制可满足各种产品形状、尺寸和用途。

蛋托生产机器的优势

- 高生产效率产量范围从每小时1,000到7,000个;多种型号可供选择

- 全自动化集成纸浆供应、转模和干燥系统,实现自动化操作

- 灵活的模具更换支持铝或铜模具定制,以适应不同产品类型

- 耐用结构重型钢框架确保持久性能

出售蛋托成型机

我们提供多种蛋箱制造机出售,旨在满足不同的生产能力和工厂条件。从小规模的手动设备到全自动高产系统,我们为您的业务提供合适的解决方案。

单面机器:3×1,4×1

这些是小规模蛋托生产机器,适合初创企业或产能有限的生产。

- 容量适合每小时1000–2000个

- 优点投资少,操作简单

- 推荐干燥:由于产量较低,建议自然阳光干燥

- 最佳适用适合小型蛋托工厂或有足够开放空间的农村地区

四面机器:3×4,4×4

这些模型非常适合中等规模的生产,相比单面蛋托成型机,提供了更高的效率和稳定的性能。

- 产能:2000–3000 个/小时

- 优点:更高的产量,可靠的操作

- 干燥选项:自然干燥 / 砖窑 / 金属干燥线

- 最佳选择:寻求干燥效率和灵活性的中型工厂

八面蛋托生产机器

这是大规模操作的热门选择,该机器提供显著更高的产量,并且需要更先进的干燥系统。

- 产能:4000–7000 件/小时(根据配置而异)

- 推荐干燥:砖窑或金属干燥线

- 最佳选择:订单量稳定且有长期生产计划的工厂

十二面蛋托机器

设计用于高产量、工业规模生产,该机器通常用于大型设施。

- 产能:7000–8000 个/小时

- 推荐干燥:金属干燥线,以实现快速、一致的干燥

- 最佳选择:拥有先进工厂设置的高产量制造商

无论您需要一台用于手动操作的小型机器,还是一台具有集成干燥的全自动蛋托制造厂,我们都可以帮助您选择最合适的型号。今天就联系我们,获取机器推荐、布局设计和定制报价。

让我们帮助您使用可靠的设备和专业的支持来启动或扩展您的蛋托生产。

为什么选择我们?

- 超过10年的纸浆成型机械制造经验

- 多种型号现货,快速交货

- 已出口到多个国家,可靠性经过验证

- 提供安装支持、技术指导和售后服务

- 根据您的工厂布局和产能量身定制完整的生产线设计

常见问题解答(FAQ)

Q1:机器可以处理哪些原材料?

答:主要是废纸板、报纸和纸板。这些材料在成型之前会被加工成纸浆。

Q2:模具尺寸可以定制吗?

答:是的。我们支持根据客户样品或图纸定制模具设计。

Q3:每台机器需要多少操作员?

答:一般来说,自动生产线只需3-4名操作员即可。

Q4:你们提供完整的生产线吗?

答:是的。我们提供包括制浆、成型、干燥、热压和堆叠在内的完整解决方案。