La cizalla de pórtico para chatarra de metal es una pieza esencial de equipo en las plantas modernas de reciclaje de metales. Está diseñada para cortar y procesar chatarra metálica voluminosa en piezas más pequeñas y uniformes, facilitando su almacenamiento, transporte y procesamiento adicional como fusión o fundición. Esta máquina se utiliza ampliamente en patios de chatarra, aceros y centros de reciclaje que manejan placas de acero, vigas en I, cuerpos de automóviles, varilla, tuberías y perfiles metálicos ligeros.

Para los clientes que buscan mejorar la eficiencia de producción y reducir el trabajo manual, una cizalla de pórtico ofrece una solución automatizada y confiable.

¿Qué es una Cizalla de Pórtico y Cómo Funciona?

Una cizalla de pórtico para chatarra de metal, también conocida como máquina cizalla hidráulica para chatarra de metal, es un equipo de alta resistencia diseñado para cortar grandes volúmenes de chatarra de metal en piezas más pequeñas, manejables y densas.

El proceso operativo es un modelo de eficiencia y automatización:

- Carga: La chatarra se carga en la caja de alimentación de material larga y espaciosa usando una grúa de agarre u otro equipo de carga.

- Compactación: Un cilindro hidráulico de prensado o una tapa de sujeción comprime la chatarra cargada desde el lateral o superior, compactando el material suelto para garantizar un corte limpio y eficiente.

- Alimentación: Un mecanismo de alimentación automatizado—ya sea una cabeza de empuje de doble cadena robusta o un cilindro hidráulico potente—empuja la chatarra compactada hacia las cuchillas de corte.

- Corte: Los cilindros principales de corte activan, haciendo que la cuchilla superior descienda con una fuerza inmensa (que va desde 630 hasta más de 2000 toneladas) para cortar el metal.

- Repetición del Ciclo: El sistema repite automáticamente este ciclo de alimentación y corte, procesando continuamente el material en la caja hasta que esté vacía. Todo el proceso puede ser gestionado de forma segura por un solo operador a través de un armario de control PLC o un control remoto inalámbrico.

Video de Trabajo de la Cizalla de Pórtico para Chatarra

Aplicaciones Clave: ¿Dónde es Esencial la Cizalla Hidráulica de Pórtico?

La versatilidad y el inmenso poder de una cizalla de pórtico para chatarra de metal la convierten en una pieza fundamental de equipo en varios sectores industriales. Su capacidad para manejar una amplia gama de materiales la convierte en una inversión rentable para:

- Patios de Reciclaje de Chatarra: Para procesar chatarra pesada mixta, vigas en I, vigas H, barras de refuerzo, placas de acero y vehículos fuera de uso (ELV).

- Acero y Fundiciones: Para reducir el tamaño de la chatarra comprada o de la chatarra de producción interna para que sea apta para el horno, mejorando la eficiencia de fundición y el manejo.

- Instalaciones de Desmantelamiento de Automóviles: Ideal para cortar carrocerías y chasis compactados, simplificando el proceso de separación y reciclaje de materiales.

- Talleres de Fabricación de Metales a Gran Escala: Para gestionar y reciclar grandes recortes y placas esqueletales de procesos de fabricación.

- Proyectos de Demolición: Para procesar acero estructural y otros grandes residuos metálicos directamente en el sitio o en una instalación de procesamiento.

Las Ventajas de Elegir una Cizalla Hidráulica de Pórtico Shuliy

Fuerza de Corte para Materiales de Alta Resistencia

Con una gama de modelos que ofrecen fuerzas de corte nominales de 630 toneladas a 2000 toneladas (y modelos personalizados más grandes disponibles), nuestra cizalla de pórtico para chatarra puede cortar sin esfuerzo a través de la chatarra más dura. Este poder bruto asegura que pueda procesar una variedad más amplia de materiales, aumentando el alcance y la rentabilidad de sus operaciones.

Construcción Robusta y Superior Durabilidad

- Cabezas de Corte de Acero Fundido: Resistente a una presión y desgaste inmensos, asegurando una larga vida útil.

- Diseño Avanzado de Deslizamiento: Nuestros modelos más grandes cuentan con un diseño de deslizamiento de tres lados para la pista del bloque de corte, incrustado con bronce y placas resistentes al desgaste de aleación 55SiCr. Esto reduce la fricción, garantiza un funcionamiento más suave y extiende dramáticamente la vida útil de la máquina.

- Sistema de Lubricación Automatizado: Una bomba automática lubrica con precisión las guías de deslizamiento, minimizando el desgaste y reduciendo los requisitos de mantenimiento.

Alta Eficiencia y Operación Automatizada

- Control PLC y Operación Remota: El avanzado sistema PLC permite ciclos totalmente automáticos o semiautomáticos. El control remoto inalámbrico incluido mejora la seguridad del operador permitiéndole gestionar la máquina desde una distancia segura, lejos de la zona de corte.

- Tiempos de Ciclo Optimizados: Con frecuencias de corte de 3-5 veces por minuto, nuestras máquinas ofrecen un alto rendimiento, permitiéndote procesar más toneladas por hora.

- Sistemas de Alimentación Eficientes: Ofrecemos tanto alimentación con cabeza de empuje de doble cadena para aplicaciones estándar como empuje con cilindro hidráulico para nuestros modelos más potentes, asegurando una alimentación de material constante y fiable.

Modelos Versátiles para Adaptarse a Su Escala Operativa

Reconocemos que cada operación es única. Nuestra cizalla de pórtico para chatarra incluye una variedad de tamaños y configuraciones para adaptarse perfectamente a sus necesidades específicas, desde patios de tamaño mediano hasta los mayores aceros. Ya sea que necesite una caja de alimentación compacta de 6 metros o una caja masiva de 8 metros con una apertura de corte más amplia, tenemos un modelo que se adapta.

Nuestros Modelos de Cizalla de Pórtico: Una Visión Técnica

Para ayudarle a identificar la cizalla de pórtico para chatarra adecuada para sus necesidades, aquí tiene un resumen comparativo de nuestros modelos populares. Tenga en cuenta que las especificaciones se pueden personalizar.

| Característica | Modelo-630 | Modelo-800 | Modelo-1500 (Alimentación por Cadena) | Modelo-2000 (Alimentación por Cilindro) |

| Máxima Fuerza de Corte | 630 Toneladas | 800 Toneladas | 1500 Toneladas | 2000 Toneladas |

| Tamaño de Caja de Material (LWH) | 6000*1500*800 mm | 8000*1800*1200 mm | 8000*2400*1000 mm | 8000*2100*900 mm |

| Ancho de Corte | 1600 mm | 1800 mm | 2500 mm | ≤ 2200 mm |

| Potencia Total del Motor | 130 KW | 180 KW | 290.7 KW | 425 KW |

| Método de Alimentación | Empuje de Doble Cadena | Empuje de Doble Cadena | Empuje del Cilindro Hidráulico | Empuje del Cilindro Hidráulico |

| Sistema de Refrigeración | Refrigeración por Aire Forzado | Refrigeración por Aire Forzado | Refrigeración por Ciclo de Agua | Refrigeración por Agua Forzada |

| Sistema de Control | PLC + Control Remoto | PLC + Control Remoto | PLC + Control Remoto | PLC + Control Remoto |

Este es un resumen de las especificaciones clave. Para una hoja de datos técnicos completa, por favor contáctenos.

Otro Equipo de Reciclaje de Metales

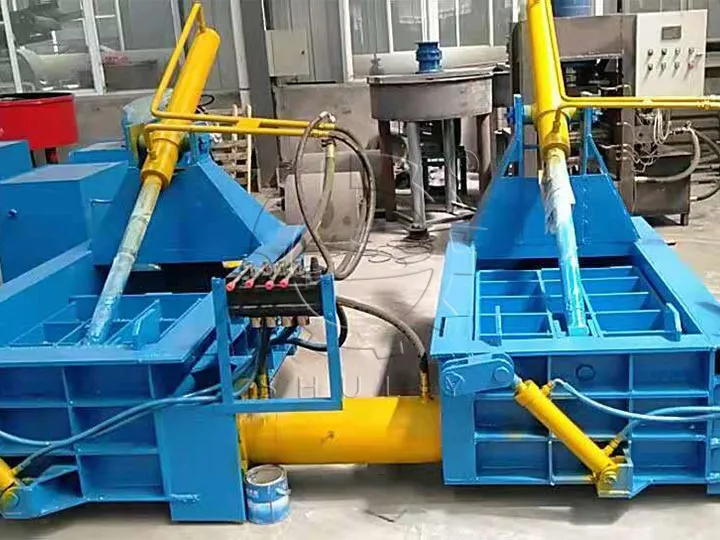

En las operaciones de reciclaje de metales, además de utilizar una cizalla de pórtico para chatarra para cortar materiales de chatarra, muchos clientes también eligen otro equipo para mejorar aún más la eficiencia del procesamiento.

- Para chatarra metálica voluminosa y suelta, se puede utilizar primero un triturador de metales para descomponerla en piezas más pequeñas, facilitando la clasificación y la fusión.

- Si el objetivo es reducir el volumen de chatarra para facilitar su almacenamiento y transporte, un prensa de chatarra metálica puede comprimir chatarra de acero, aluminio, cobre y otros metales en fardos densos, reduciendo los costes logísticos.

Estas máquinas operan de forma independiente y se pueden comprar por separado según las necesidades específicas, ayudando a los clientes a manejar diferentes tipos de chatarra de manera más eficiente.

¿Por qué asociarse con Shuliy Machinery?

- Consulta de Expertos: Trabajamos con usted para entender sus necesidades de procesamiento y recomendar la configuración de máquina perfecta.

- Manufactura de Calidad: Nos adherimos a estrictos estándares de control de calidad para ofrecer maquinaria que sea confiable, eficiente y construida para soportar los entornos industriales más duros.

- Soporte Global: Ofrecemos un soporte integral postventa, incluyendo instalación, capacitación y disponibilidad de piezas de repuesto, para asegurar que su equipo opere al máximo rendimiento.