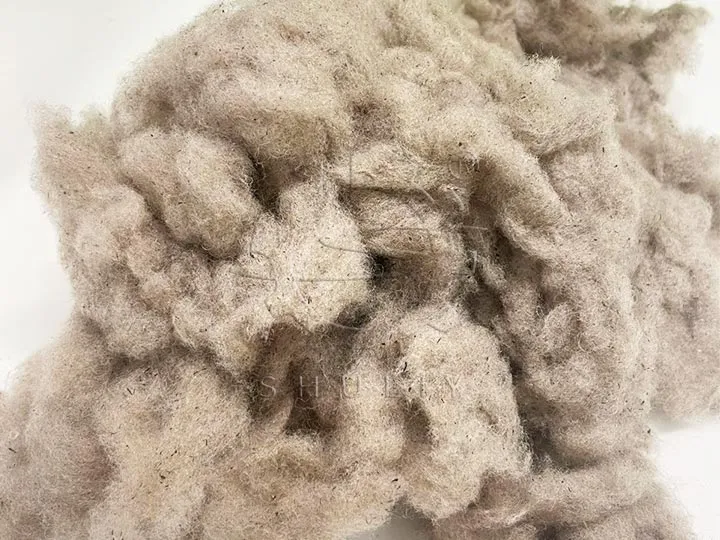

En el reciclaje textil, el procesamiento de algodón reciclado o el proceso de fabricación de rellenos, la materia prima a menudo se presenta en forma de masa, un estado comprimido, difícil de utilizar directamente. Aquí es donde una máquina de apertura de fibra altamente eficiente es esencial. Ofrecemos una gama de máquinas de apertura diseñadas para descomponer una amplia variedad de materiales fibrosos, que son una parte esencial del reciclaje textil.

¿Qué es una máquina de cardado de fibra?

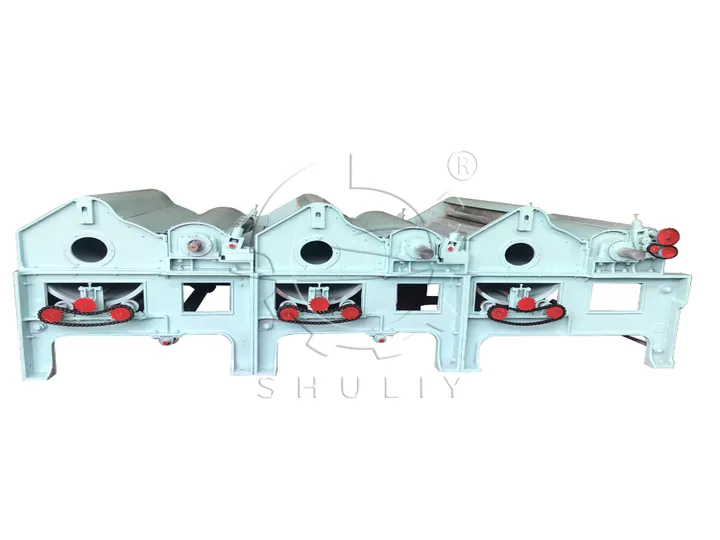

Una máquina abridora de fibras, también conocida como abridor de fibras o máquina de cardado de algodón, es un dispositivo industrial utilizado para abrir y separar materiales fibrosos agrupados o comprimidos, como textiles desechados, retazos de tela, fibras sintéticas, plumas y más. Con rodillos de alta velocidad y un potente sistema de flujo de aire, la máquina descompone eficazmente los paquetes de fibra mientras elimina el polvo y las impurezas ligeras.

Se utiliza típicamente en conjunto con una máquina de corte de fibra, máquina de relleno de algodón, máquina enfardadora de textiles, etc. Se utiliza en el relleno de juguetes, algodón absorbente de sonido, material de aislamiento térmico, interiores de automóviles y otras industrias.

Amplia gama de materiales aplicables

Nuestro abre fibras es adecuado para procesar:

- Ropa desechada y retazos de tela

- Poliéster, algodón, lana, lino, yute, fibras sintéticas

- Plumas, espuma EPE, esponja triturada, desechos de juguetes de peluche

- Tejidos no tejidos, fieltro industrial, acolchado reciclado

- Otros materiales fibrosos suaves y compresibles

Características clave y ventajas de la máquina de apertura de fibra

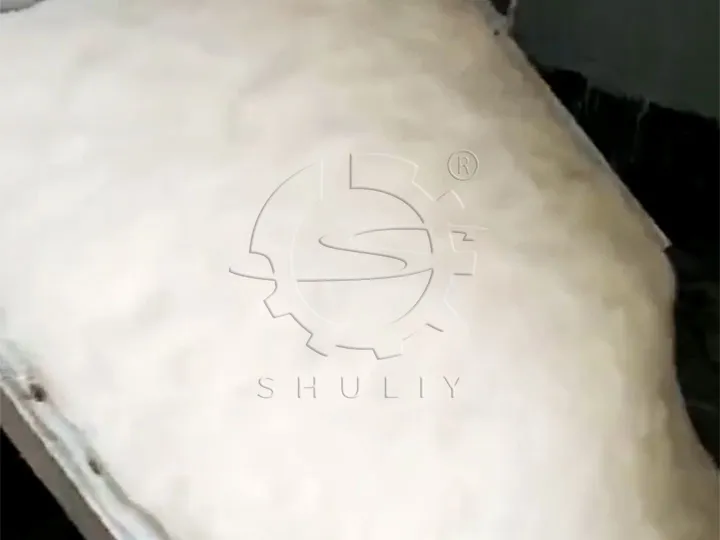

- Eficiencia de Apertura Alta:Un diseño de diente de rack completamente nuevo permite el procesamiento progresivo de materias primas, reduciendo significativamente el daño a las fibras y mejorando enormemente la longitud de las fibras.

- Eliminación de Polvo e Impurezas IntegradaFiltra el polvo fino, fibras cortas e impurezas durante la apertura.

- Configuraciones de Múltiples Rodillos Disponibles: Soporta configuraciones de 2 rollos, 4 rollos y múltiples rollos para diferentes tipos de fibra y profundidades de procesamiento.

- Soporta una variedad de formas de alimentación, para que se puedan elegir diferentes materias primas a voluntad.

Parámetros técnicos de la máquina de apertura de algodón

| Parámetro | Especificación |

| Capacidad de salida | 100 – 350 kg/h |

| Materiales aplicables | Fibra de poliéster, fibra de algodón, retales de tela, plumas, esponja triturada y otras fibras suaves |

| Rodillos de apertura | 1-rollo, 2-rollos, 4-rollos y multi-rollos |

| Potencia del motor | 5.5 – 25.5 kW (dependiendo de la configuración) |

| Principio de funcionamiento | Rodillo dentado de alta velocidad |

| Eliminación de impurezas | Eliminación de polvo primaria + sistema de filtro de malla (opcional) |

| Aplicaciones típicas | Reciclaje textil, relleno de juguetes, producción de algodón regenerado, fabricación de textiles para el hogar |

Vídeo en funcionamiento de la máquina abridora de fibra

Preguntas frecuentes (FAQs) sobre la máquina de apertura de fibra

P1: ¿La máquina dañará las fibras durante la apertura?

A: No. Nuestras máquinas utilizan un espaciado y velocidad de rodillos optimizados para aflojar las fibras sin romperlas, preservando la longitud y calidad de la fibra.

P2: ¿Puede abrir materiales mezclados?

A: Sí. Maneja tipos de fibra mezclados como mezclas de algodón-poliéster, plumas con espuma, etc.

P3: ¿Puede integrarse con otras máquinas?

Absolutamente. Se puede utilizar junto con máquinas de corte de fibra, máquinas de relleno y enfardadoras textiles.

Obtén una cotización gratuita y una solución a medida

¿Buscas una máquina de apertura de fibra duradera y de alto rendimiento para tu línea de reciclaje o de relleno? Contáctanos ahora. Te ayudaremos a seleccionar el modelo ideal según tu materia prima, necesidades de capacidad y diseño de planta.